- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

-

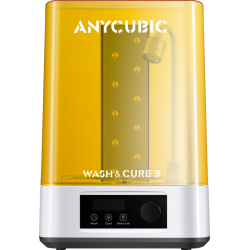

Resin washing and curing stations

Active filters

Resin washing and curing stations

3D resin polymerization is a crucial step in the 3D printing process using stereolithography (SLA), DLP, or LCD technologies. It refers to the transformation of a photosensitive liquid resin into a solid object under the effect of a light source, usually UV.

Mastering this polymerization phase is essential to ensure the quality, durability, and precision of printed parts.

What is 3D resin polymerization?

3D resin polymerization is based on a chemical reaction triggered by light. During printing, each layer of resin is exposed to UV light that initiates curing (or photopolymerization).

This phenomenon is made possible by the photoinitiators contained in the 3D resin, which react to a specific wavelength, typically between 365 and 405 nm.

Primary vs post-curing polymerization

- Primary polymerization: occurs during printing. Each layer is partially cured immediately after exposure to light, but remains slightly soft to allow proper adhesion between layers.

- Post-curing: once printing is complete, the object must be cleaned (usually with isopropyl alcohol), then fully cured in a UV chamber or a post-curing station. This step helps achieve the optimal mechanical and thermal properties of the material.

Why is polymerization so important?

Proper polymerization ensures:

- uniform hardening of the part

- excellent dimensional stability

- enhanced mechanical properties (strength, rigidity, flexibility… depending on the resin type)

- biocompatibility in the case of dental or medical resins

- optimized surface finish for aesthetic or functional parts

Which equipment is used for post-curing?

To ensure complete polymerization, it is recommended to use suitable equipment:

- Professional UV chambers: they provide uniform UV exposure and controlled temperature for effective curing.

- Combined wash and cure stations: they simplify post-processing by integrating cleaning and curing into a single device.

Conclusion

3D resin polymerization is not limited to the printing step; it is a key factor in the success of your prints.

Well-cured resin ensures optimal performance, greater durability, and an impeccable finish. For professional results, it is essential to use quality post-processing equipment and follow the resin manufacturer’s recommended settings.