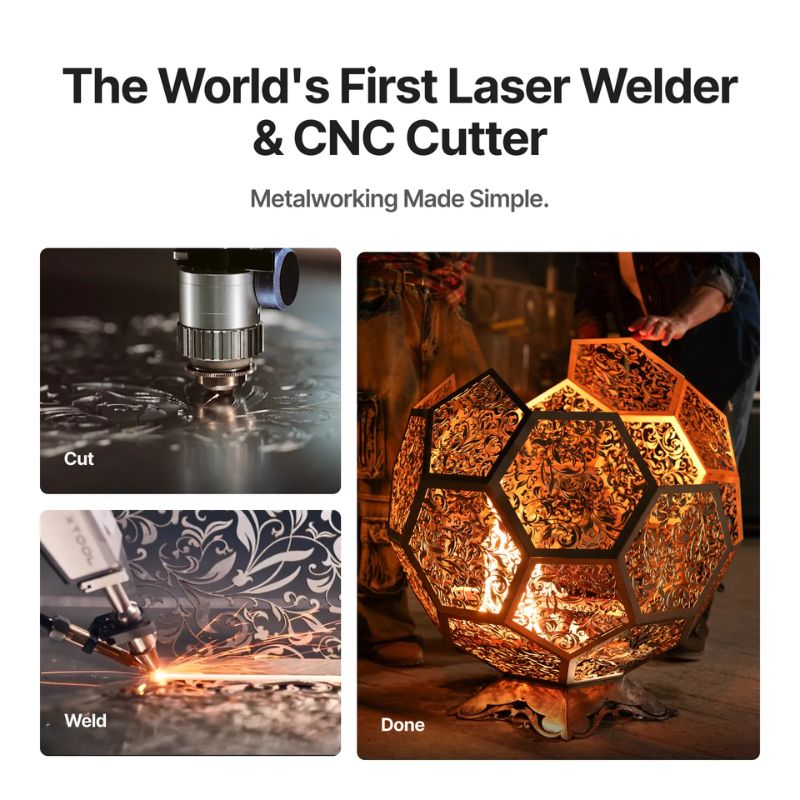

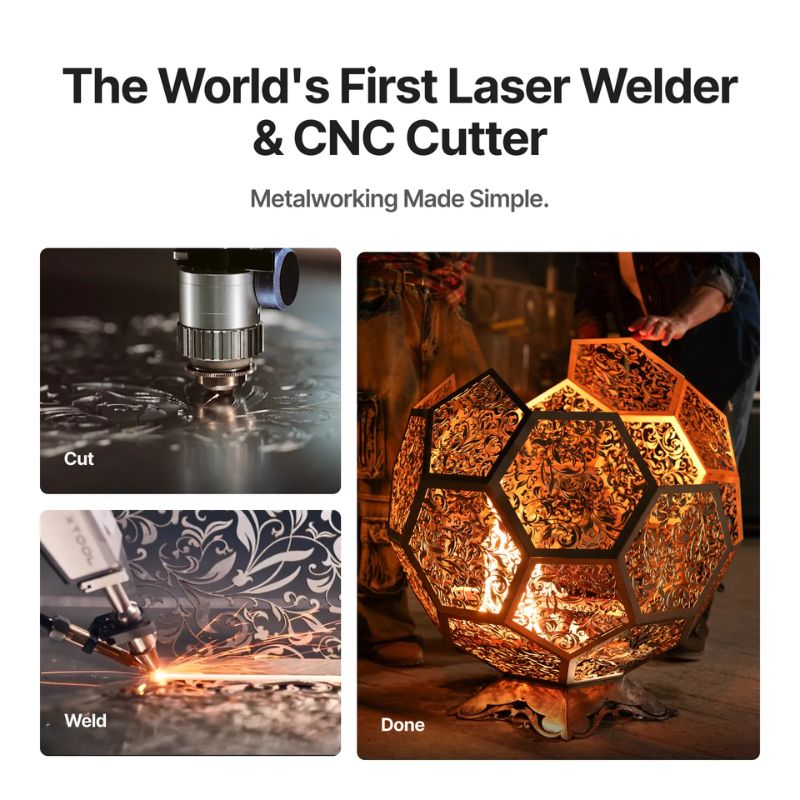

The xTool MetalFab 1200W combines high-power laser welding and precision CNC cutting in a single professional machine.

A complete industrial solution for working with steel, stainless steel, aluminum and more. Achieve precise welds, high-quality cuts, and efficient cleaning for finished parts in less time.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

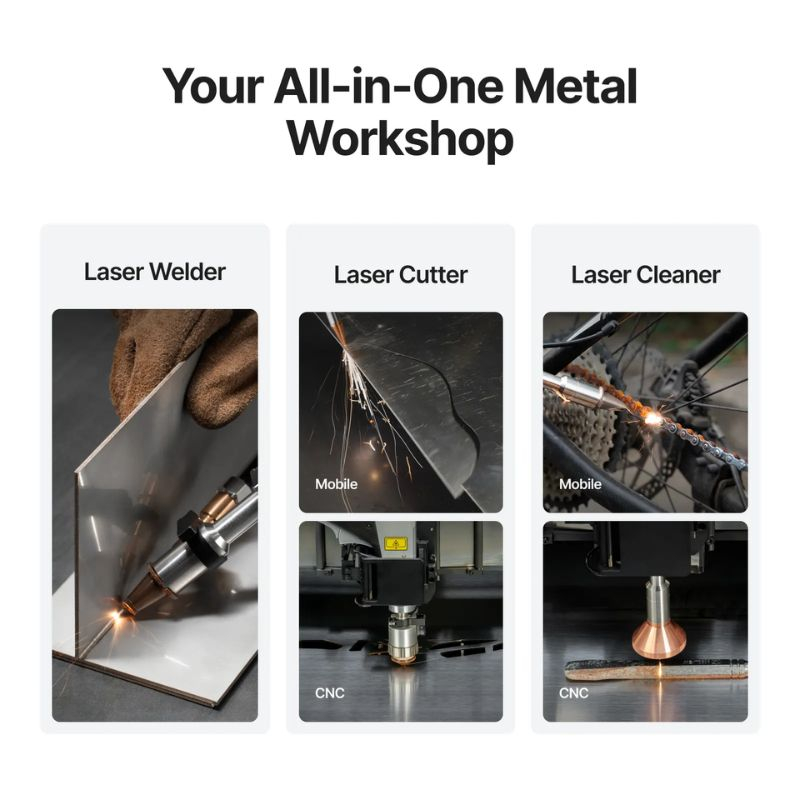

The xTool MetalFab 1200W is an all-in-one machine that combines laser welding, CNC cutting, and cleaning. Designed for metal professionals, it offers power, precision, and flexibility.

Thanks to its advanced technology, you gain efficiency while achieving flawless finishes on a wide range of metals.

The xTool MetalFab 1200W brings together the power of a laser welding unit and the precision of a CNC cutter in a single mobile solution. It meets the demands of modern workshops requiring productivity, mobility, and high accuracy.

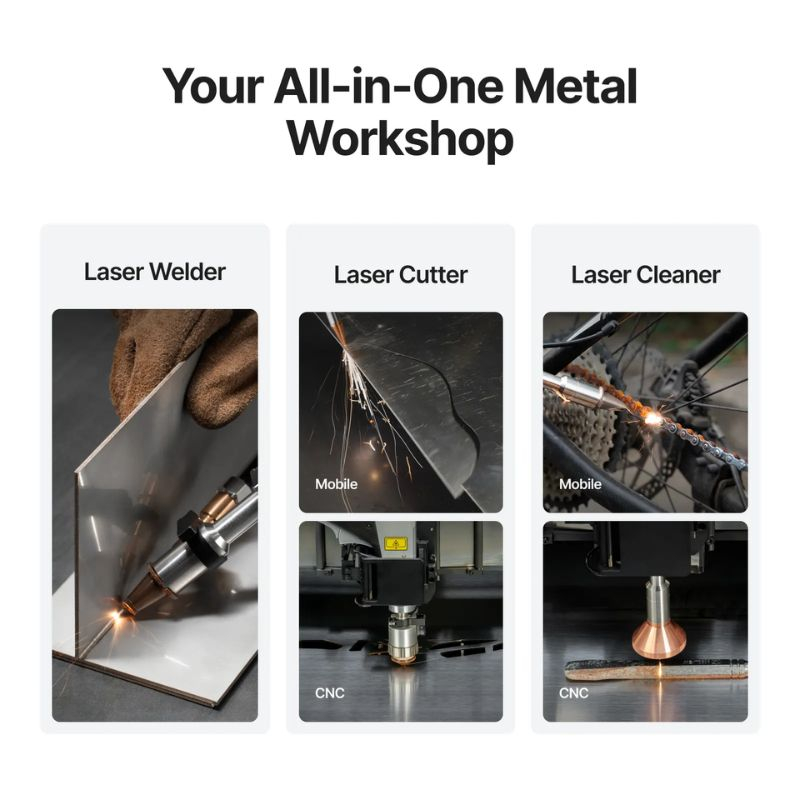

Weld, cut, and clean without switching equipment — that’s what the xTool MetalFab enables. Instantly switch between modes to maximize your production time and minimize handling.

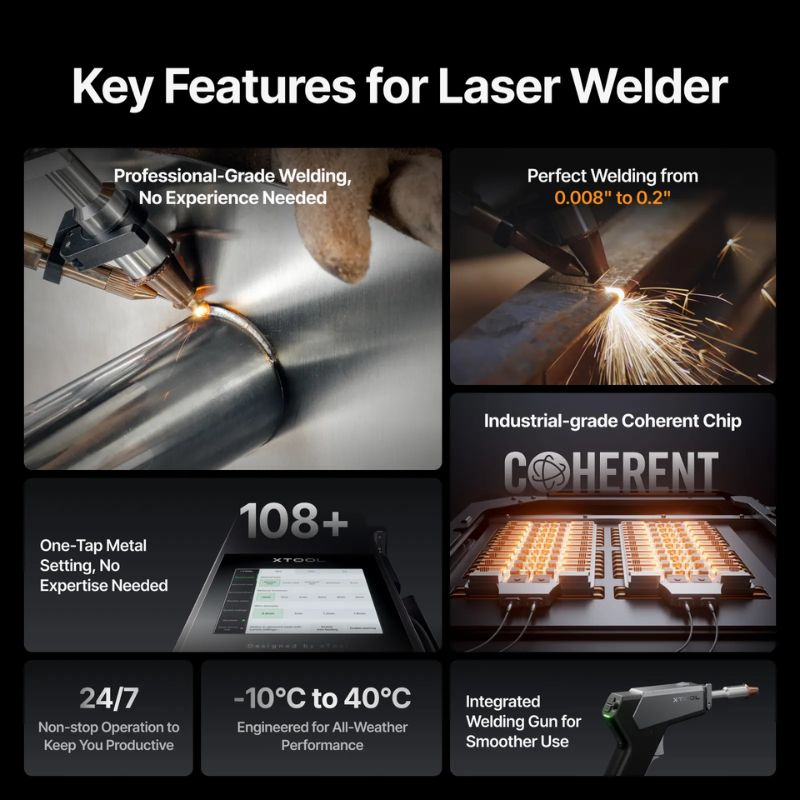

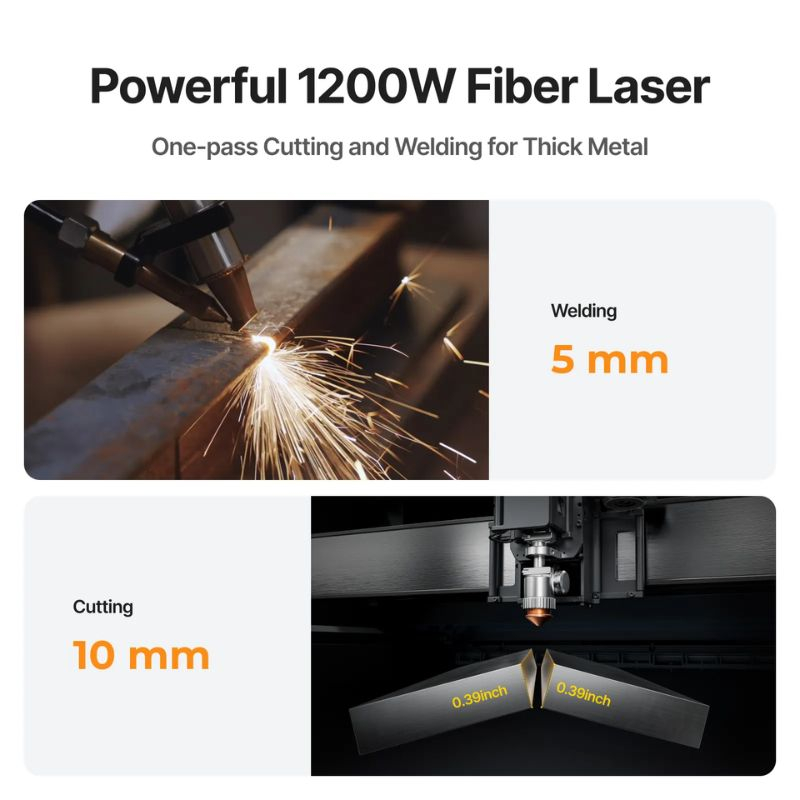

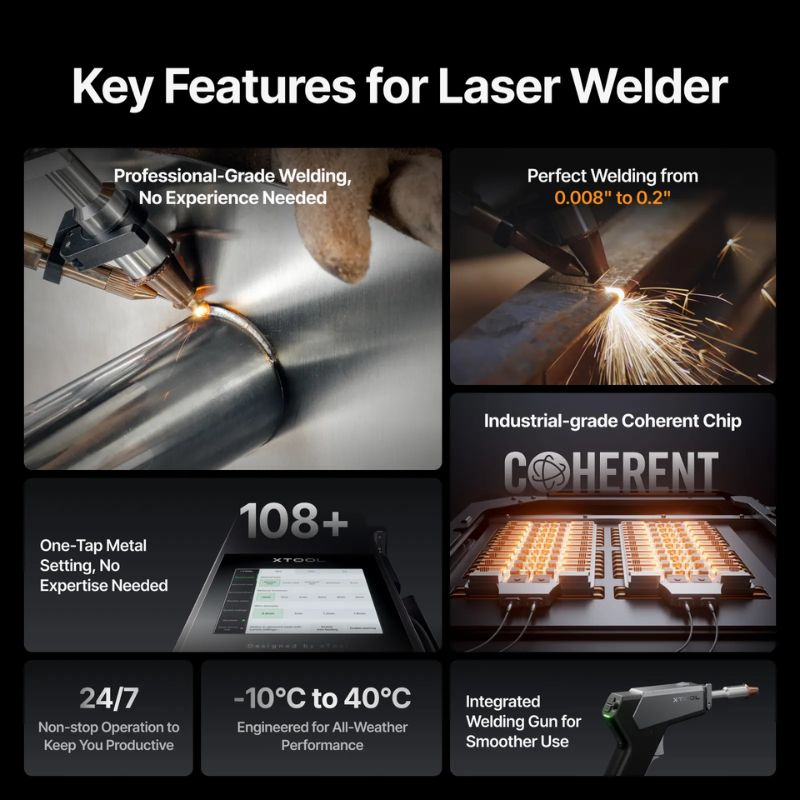

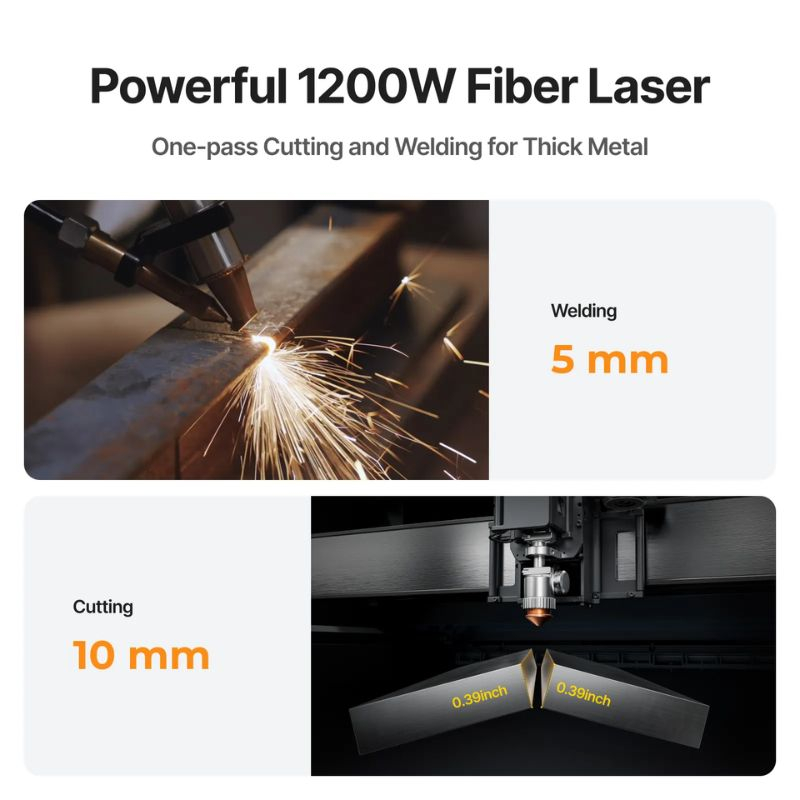

Equipped with a 1200W fiber laser, the MetalFab enables strong, clean, and fast welds, even on thick parts.

The mobile design makes it ideal for on-site work or use in tight spaces.

Achieve strong, clean, and consistent welds with industrial-grade precision in a single pass.

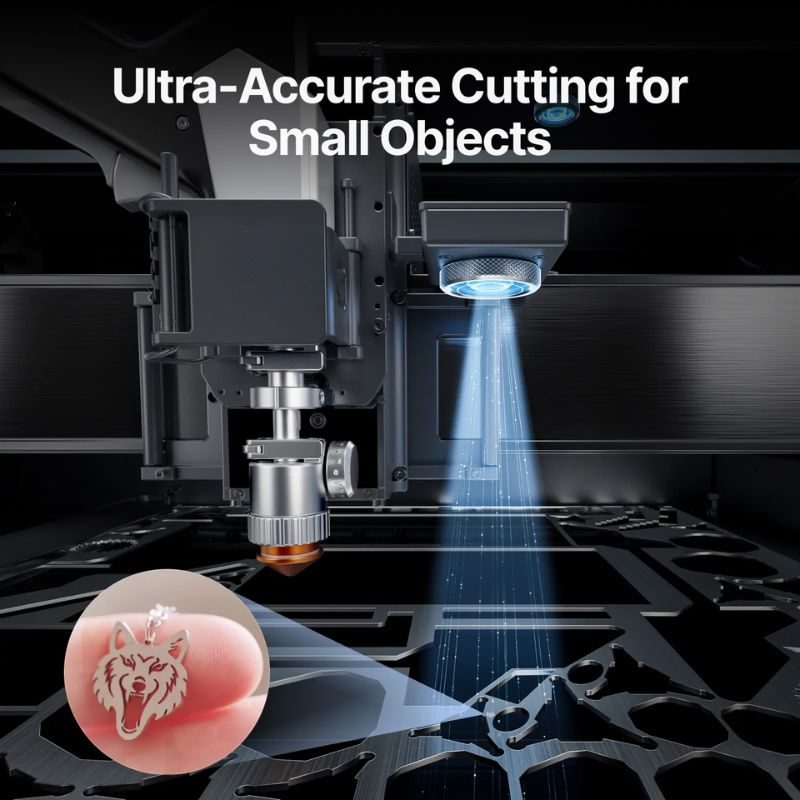

Even beginners can achieve professional results thanks to optimal beam control, minimizing the treated area with 0.05 mm precision.

The laser cleaning module features a 10 mm width to easily remove oxidation, rust, and impurities.

The nozzle activates cleaning only on contact, ensuring safety and efficiency.

Cleanly cut metal (up to 5 mm) on-site, even in narrow or hard-to-reach areas.

The high-precision laser beam ensures a burr-free cut, with no excessive heat or splatter.

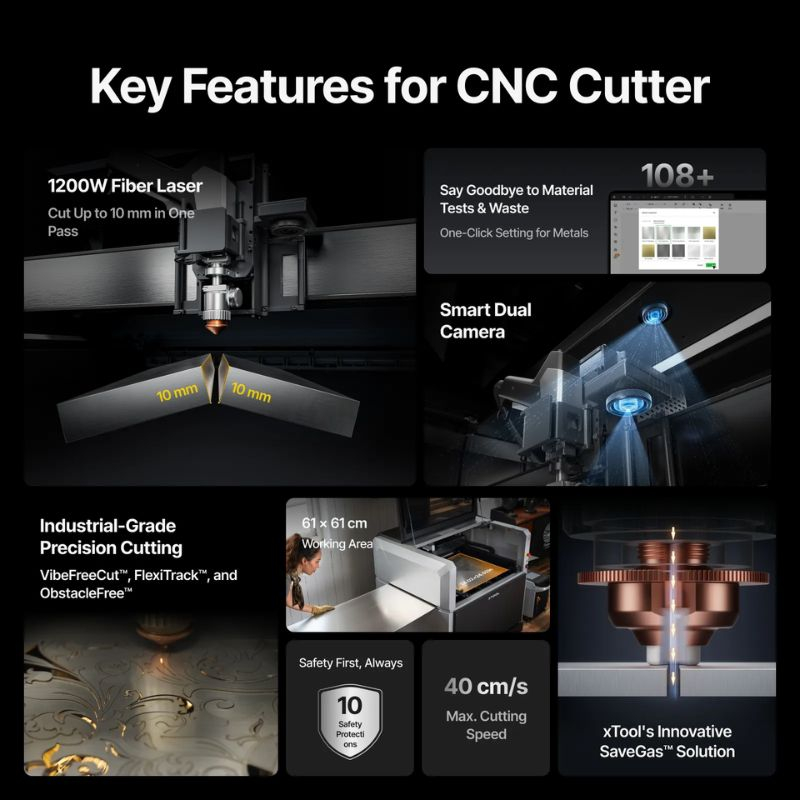

The xTool MetalFab features a high-precision CNC table for complex and automated cuts. Easily create technical or decorative metal parts.

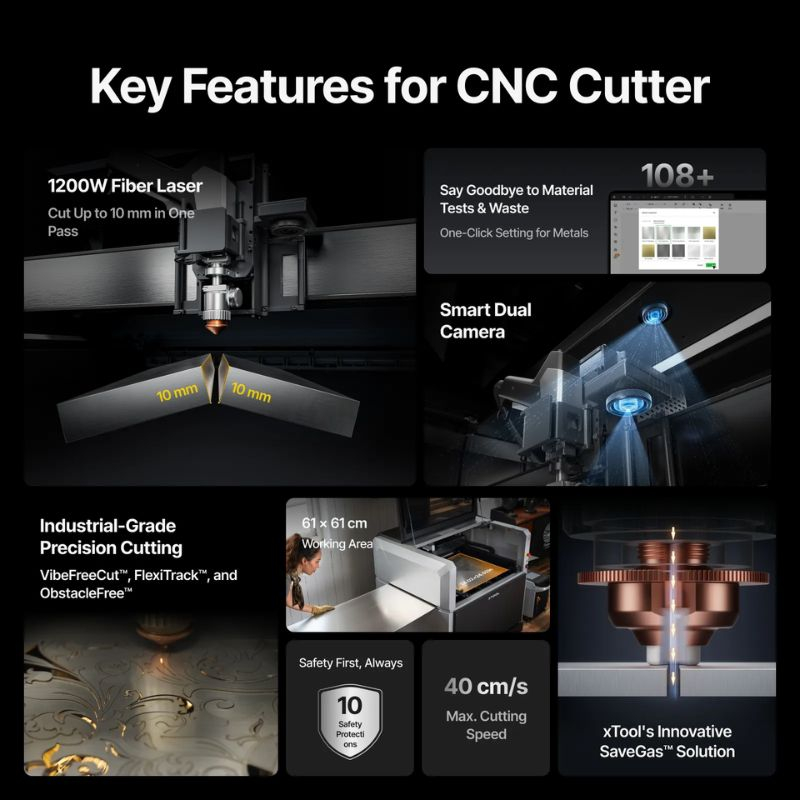

With industrial-grade precision, this machine cuts metal (up to 10 mm) exactly according to your measurements and designs, within a 610 x 610 mm working area.

Clean cuts, no rework required — ensuring maximum productivity and a professional finish.

The automated cleaning function efficiently removes paint, rust, and grime.

With a speed of 1.57 IPS, you save time and achieve excellent surface quality — no manual effort required.

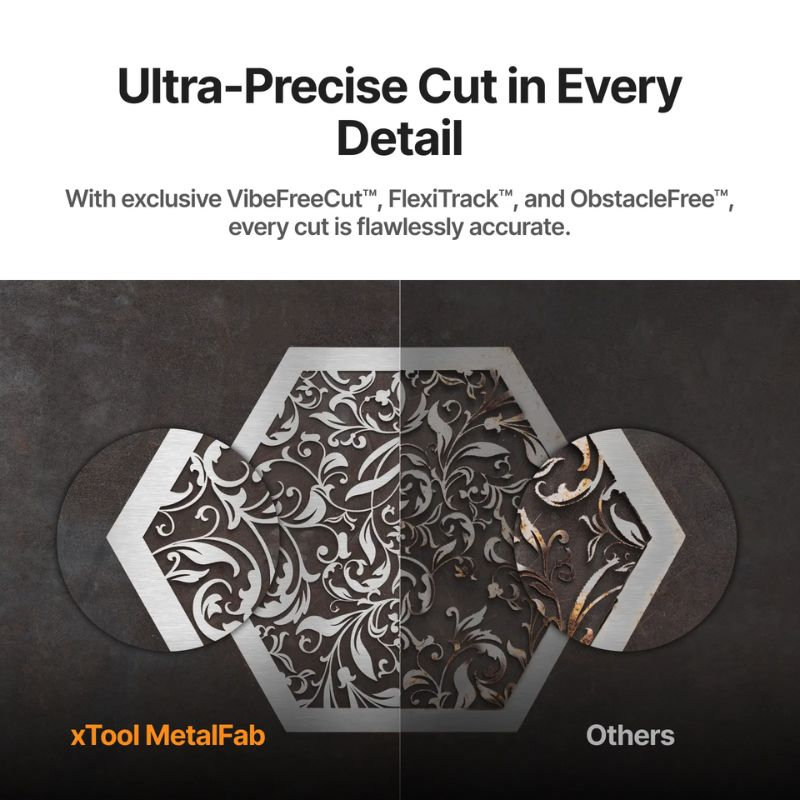

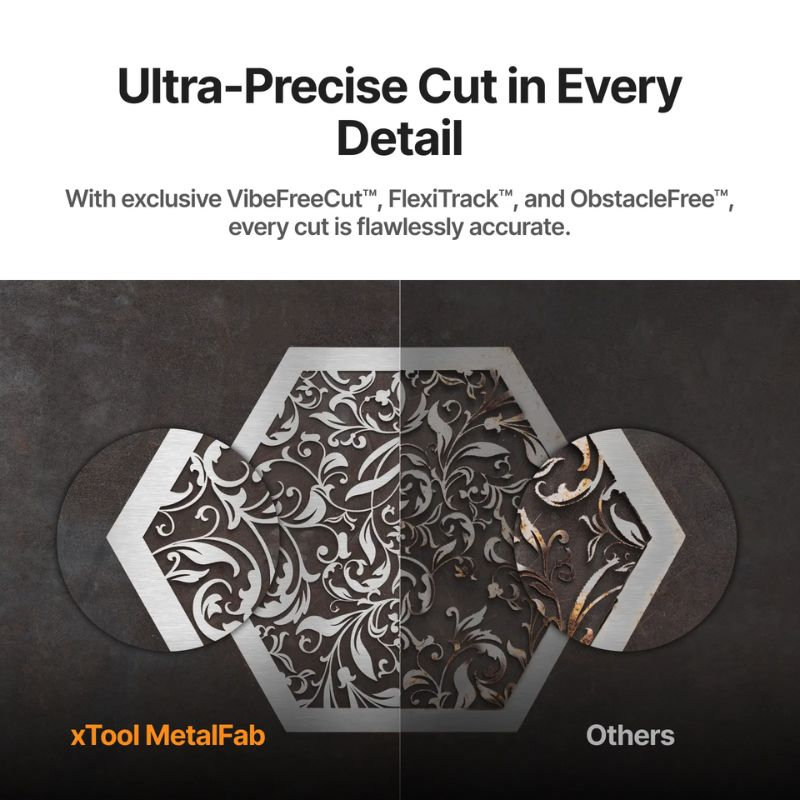

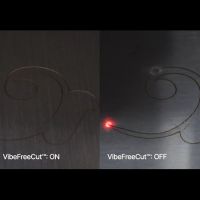

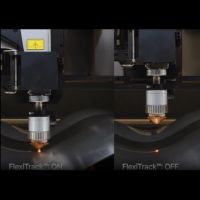

The MetalFab includes three key innovations: VibeFreeCut™, FlexiTrack™, and ObstacleFree™. These work together to provide precise, smooth, and safe cutting, no matter the design.

This technology automatically neutralizes vibrations during cutting, ensuring a stable and accurate path, even for long cuts or harder materials.

FlexiTrack™ automatically adjusts the laser height in real time based on the material, maintaining perfect focus at all times.

The result: clean, consistent cuts with no risk of blur or misalignment.

An intelligent algorithm anticipates and avoids mechanical obstacles during cutting.

This reduces interruptions, protects the equipment, and ensures smooth cutting without human intervention.

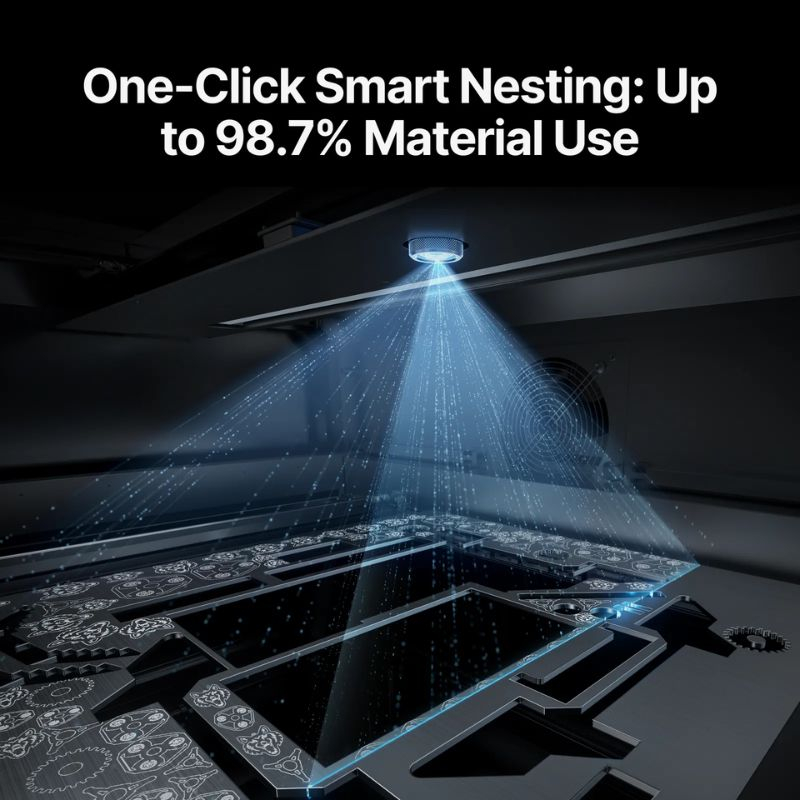

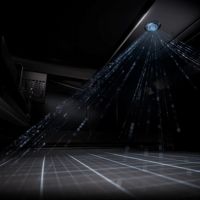

The advanced vision system simplifies alignment, preview, and material optimization. Gain speed and accuracy with minimal handling.

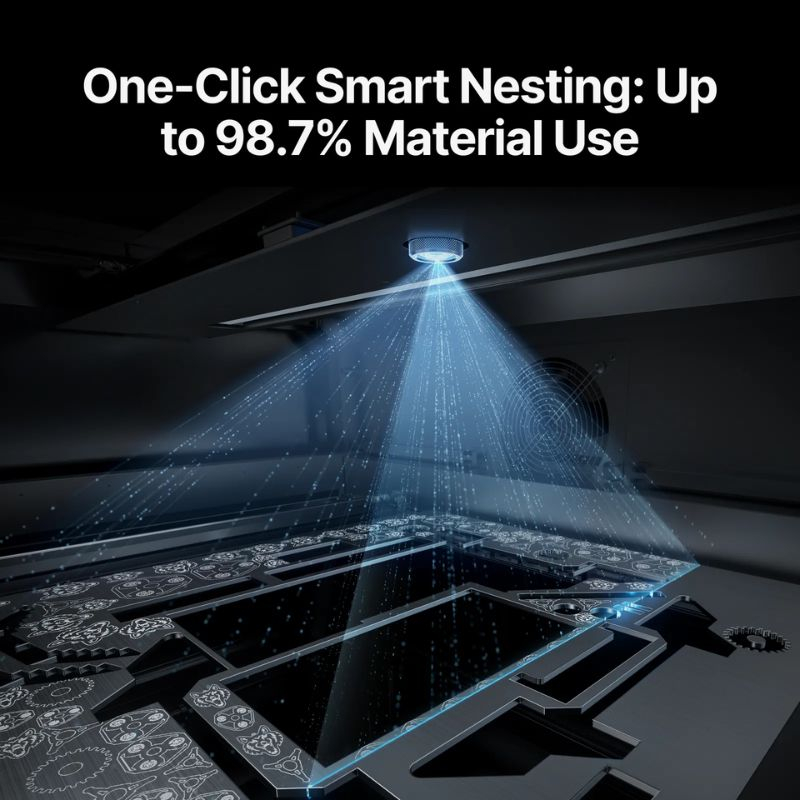

With its 16MP panoramic camera and built-in AI, the machine automatically optimizes the layout of shapes to be cut.

This maximizes material usage and reduces waste.

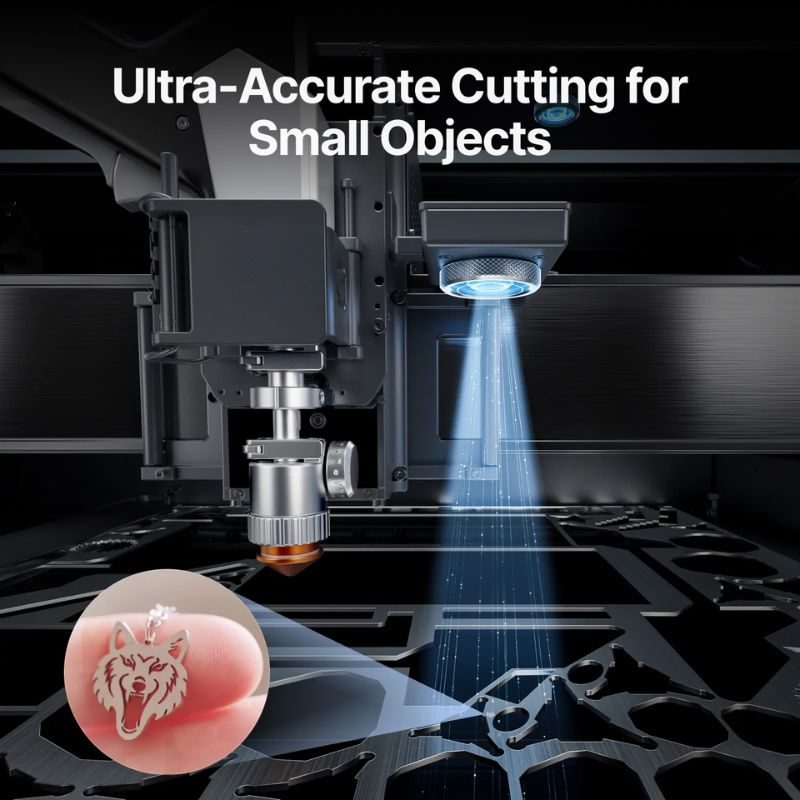

The proximity camera offers ultra-precise positioning with an error margin below 0.2 mm.

Ideal for small objects or parts requiring perfect alignment.

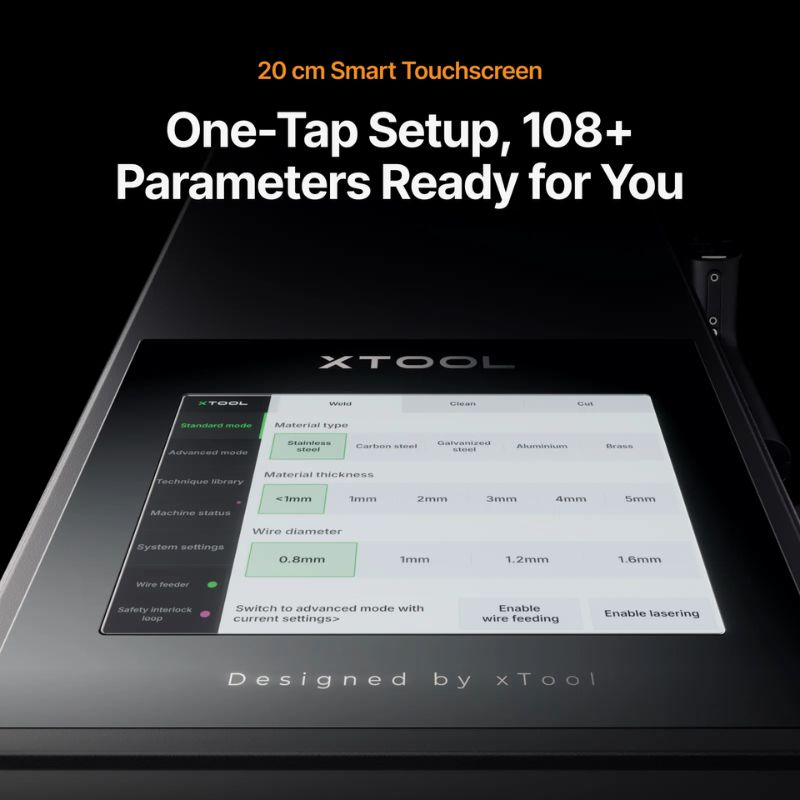

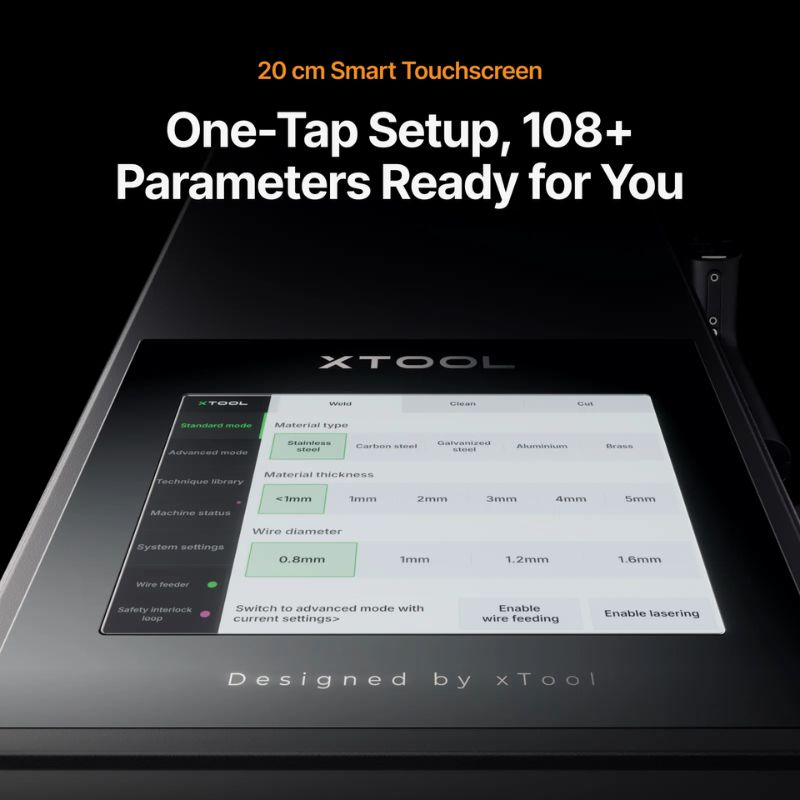

The MetalFab is designed to be easy to use and safe. Its touchscreen and multiple safety features make working pleasant and stress-free.

The 8-inch touchscreen allows easy navigation between modes.

Over 100 materials are preconfigured. Settings can be manually adjusted and saved for quick reuse.

An emergency stop button and safety sensors (closure detection, fans, temperature, etc.) protect the user in case of anomalies.

The system instantly interrupts the process to prevent any incident.

Despite its power, the machine remains mobile and easy to integrate into any workshop, large or small.

Wheels and handles facilitate movement, and the interface simplifies settings even for beginners.

With its intelligent software, the xTool MetalFab becomes a true extension of your creativity. Every feature is designed to simplify and automate key steps in your workflow.

Select your material and its settings are automatically applied. The xTool MetalFab can process the following metals: stainless steel, aluminum, brass, carbon steel, galvanized steel, titanium, nickel alloy, magnesium.

No more tedious testing: save time and reduce errors.

Describe your idea, and the artificial intelligence generates visuals ready to be cut.

This is an ideal solution to quickly go from idea to realization.

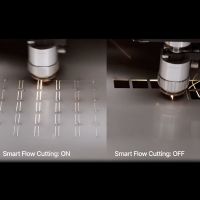

This mode automatically connects identical segments to avoid unnecessary movements.

Result: faster cutting, reduced machine wear, and improved overall efficiency.

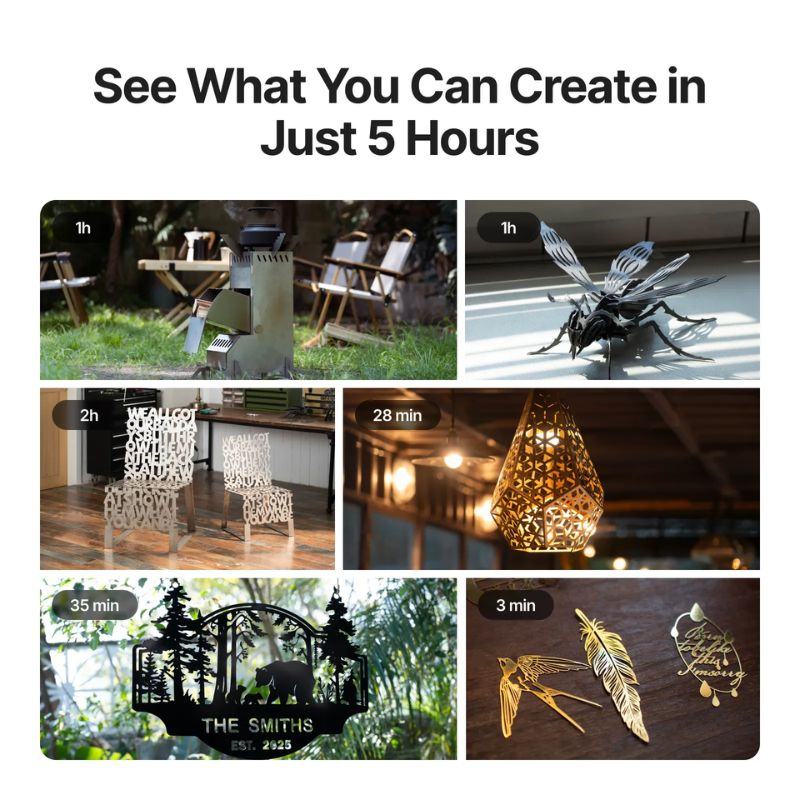

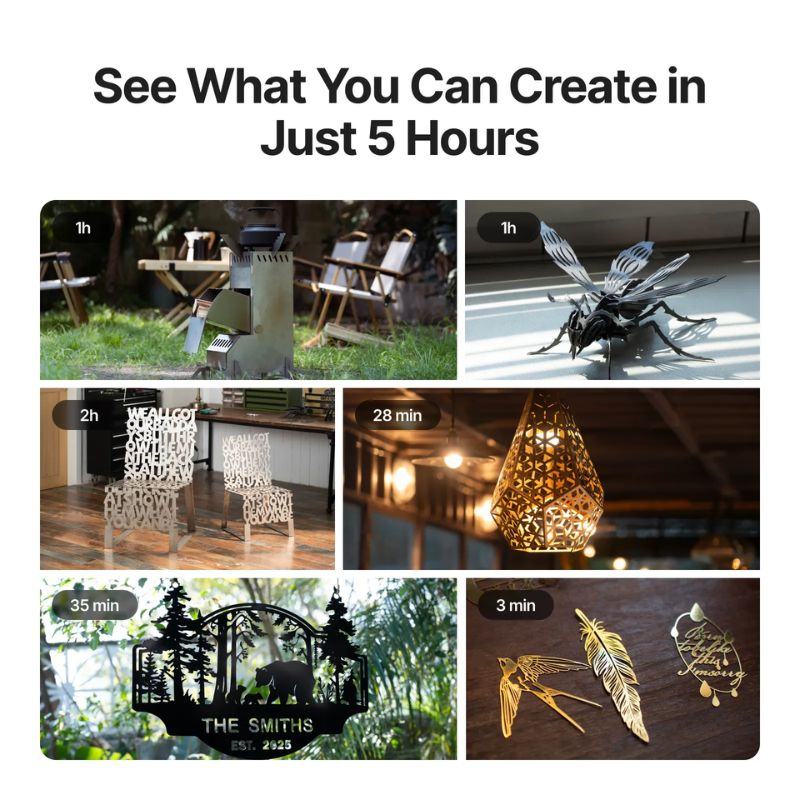

The xTool MetalFab 1200W adapts to both industry and craftsmanship. It meets the needs of manufacturers, repairers, and creators aiming to produce quickly, well, and sustainably.

From metal structures to part repairs, to furniture or design object creation: the versatility of the xTool MetalFab 1200W opens up an almost unlimited range of applications.

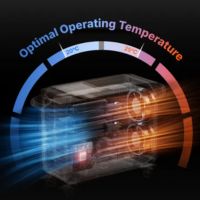

With industrial-grade materials, a Coherent chip, an intelligent cooling system, and advanced thermal management, the machine operates from -10°C to +40°C without overheating.

Its lifespan exceeds 10,000 hours.

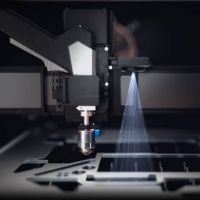

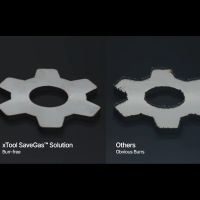

The xTool-developed SaveGas™ nozzle is designed to improve cutting efficiency while drastically reducing gas consumption.

Paired with the xTool Air Compressor and Air Dryer, this solution allows for optimized airflow management during metal material cutting.

Thanks to its ceramic ring that seals the nozzle tightly against the metal surface, the SaveGas™ nozzle ensures better directed and more efficient air pressure.

Result: to cut 4 mm stainless steel with a burr-free finish, the required pressure is only 87 PSI (0.6 MPa), compared to 174 PSI (1.2 MPa) in classic nitrogen cutting. This represents a gas saving of up to 50% without compromising cut quality.

By combining precision, energy efficiency, and consumable reduction, the SaveGas™ solution offers a considerable competitive advantage for cutting and welding workshops.

It enables extended use with a controlled budget while ensuring high finish quality on metals such as stainless steel.

The MetalFab 1200W is a powerful, versatile, and cost-effective tool designed to last. It combines the key functions of a complete metal workshop into a single piece of equipment.

By combining welding, cutting, and cleaning, you reduce equipment, labor, and production costs. It is a strategic investment to optimize every minute of work.

Benefit from professional after-sales support, readily available parts, and a solid warranty. As an official xTool reseller, Polyfab3D supports you over the long term.

The xTool MetalFab 1200W is clearly aimed at advanced users seeking a high-power laser welding machine capable of processing thick metals with remarkable efficiency. Thanks to its 1200W power, it guarantees strong and deep welds as well as ultra-precise CNC cutting, even on the most demanding materials.

It is the ideal machine for companies, craftsmen, and creators aiming for high production volumes or intensive applications. Its speed, precision, and all-in-one system (welding, cutting, cleaning) make it a premium solution perfectly suited for advanced manufacturing environments.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

1. What types of metals can be cut or welded with the xTool MetalFab?

The xTool MetalFab is designed to work with a wide range of metals: stainless steel, aluminum, brass, carbon steel, galvanized sheet metal, titanium, nickel alloys, and magnesium. It enables precise and reliable cutting and welding of these materials.

2. What is the difference between the 800W and 1200W versions?

The 1200W version offers higher capabilities, with welding up to 5 mm on stainless steel and carbon steel, compared to 4 mm for the 800W. For manual cutting, the 1200W also reaches 5 mm, while the 800W is limited to 3 mm. With the CNC table, the 1200W cuts up to 10 mm of carbon steel and 5 mm of stainless steel, whereas the 800W reaches 8 mm and 3 mm respectively. In terms of design, the 1200W includes an external wire feeder, while the 800W integrates the wire directly into the torch for lighter handling.

3. What gases should be used for welding, cutting, and cleaning?

For welding, high-purity nitrogen or argon (>99.99%) is used, especially argon for titanium. For cutting, depending on the material and desired result, you can use compressed air, nitrogen, argon, or oxygen. Cleaning is effectively done with compressed air, but nitrogen or argon provide a shinier finish without oxidation marks.

4. Can you engrave with the xTool MetalFab?

Yes, the MetalFab also allows laser engraving on stainless steel, titanium, galvanized sheet metal, and coated metals such as anodized aluminum. However, be cautious with highly reflective surfaces like copper, which could damage the laser beam.

5. What are the power supply requirements?

The xTool MetalFab operates on a 200–240V power supply with a maximum consumption of about 4200W (21A). It is recommended to have a dedicated circuit with appropriate protections. Necessary cables are provided, but an electrician is required for installation.

6. Is it easy to use, even for beginners?

Yes, the MetalFab is designed to be accessible: its handling is intuitive, even for users with no welding experience. The 8-inch touchscreen interface offers over 100 predefined settings. The lightweight torch (550 g) and quick tool changes improve comfort and efficiency.

400 mm/s

Métal, Stainless steel, Aluminium, Brass, Carbon steel, Galvanized sheet, Titanium, Nickel alloy, Magnesium

Specifications for xTool MetalFab Laser Welder and CNC Cutter 1200W

Technology / Product

Machine tools

Specific equipment

Installation / Prerequisites