- -35%

- Made In France

- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

-

Medical / Antibacterial

Active filters

Medical / Antibacterial

The medical filament category includes materials that meet specific standards related to the healthcare or medical field.

These filaments, with different properties, are classified according to current regulations for varying levels of contact with skin or mucous membranes. You will also find filaments with antibacterial properties, capable of limiting or eliminating the spread of viruses.

These so-called medical filaments generally comply with the class I requirements (non-measuring and non-sterile), meaning these 3D filaments are suitable for non-invasive, non-intrusive, and mostly therapeutic, accessory, or educational medical device applications.

Classification of medical filaments

As with filaments suitable for food contact, maintaining certification throughout your transformation process (here, 3D printing) is your responsibility. For class I devices or accessories, a simple declaration may suffice.

All other applications in classes Ia(s) / Ia(m), II, III require a file submission before any commercialization or certification. Note that PEEK-type filaments are not compatible with all 3D printers. This inert plastic used in implantology is outside the scope. It is important to assess the feasibility of your therapeutic or medical project carefully.

Filaments with antibacterial or virucidal properties have a real active effect. Integrating active particles into your PLA filaments or flexible filaments acts effectively against viruses. The manufacturer Nanovia even claims 99.9% virus destruction within 4 hours. These filaments were developed after the COVID-19 crisis and, certified ISO 21702, now meet health and safety standards.

Why choose a medical filament?

The medical world is highly regulated, and any application linked to this field includes stricter requirements than other work environments. Any object considered a medical device, even without that intent, must meet various standards.

Choosing your medical filament should be done carefully and pragmatically. Choosing a filament with favorable or certified properties is essential.

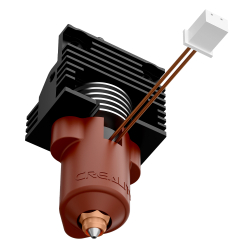

Available in 1.75 mm and 2.85 mm, with varying levels of technicality, our selection of medically oriented spools requires special attention to the condition of your equipment. Perform a thorough and careful cleaning of your extrusion system and avoid contaminating the material during processing. Also, consider using a steel nozzle!