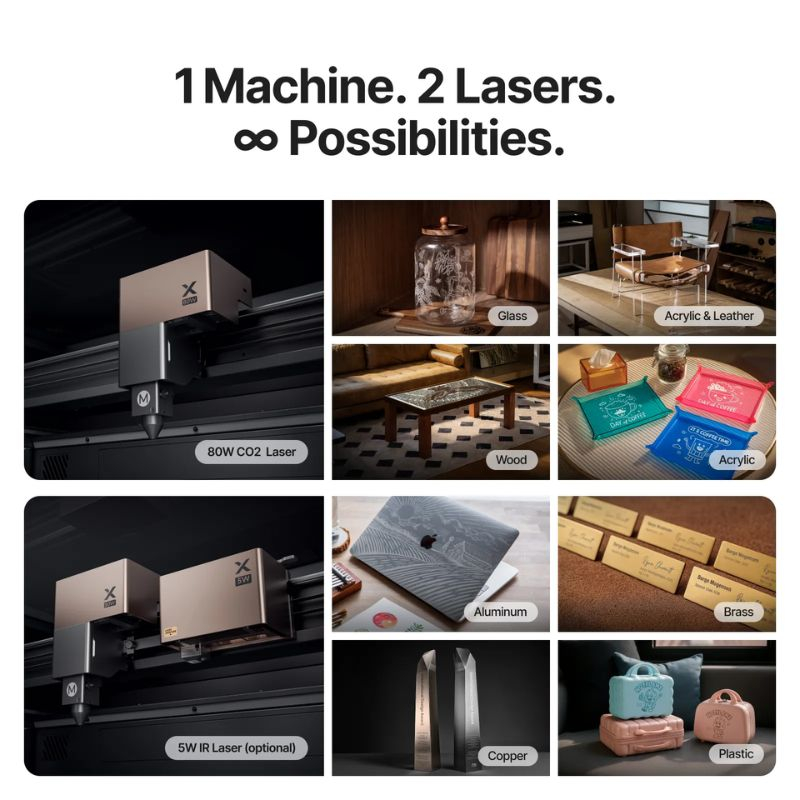

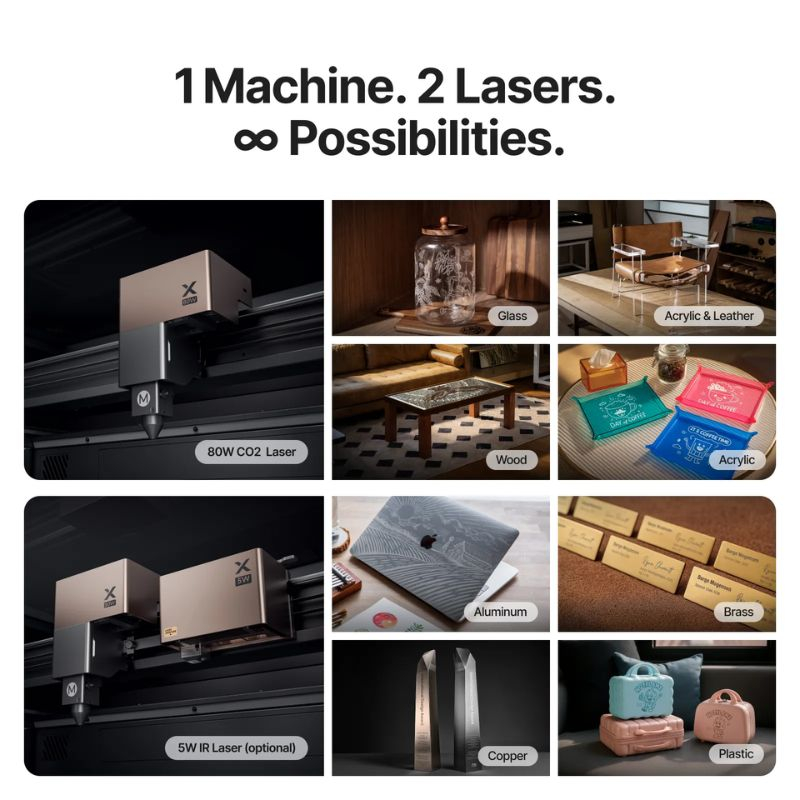

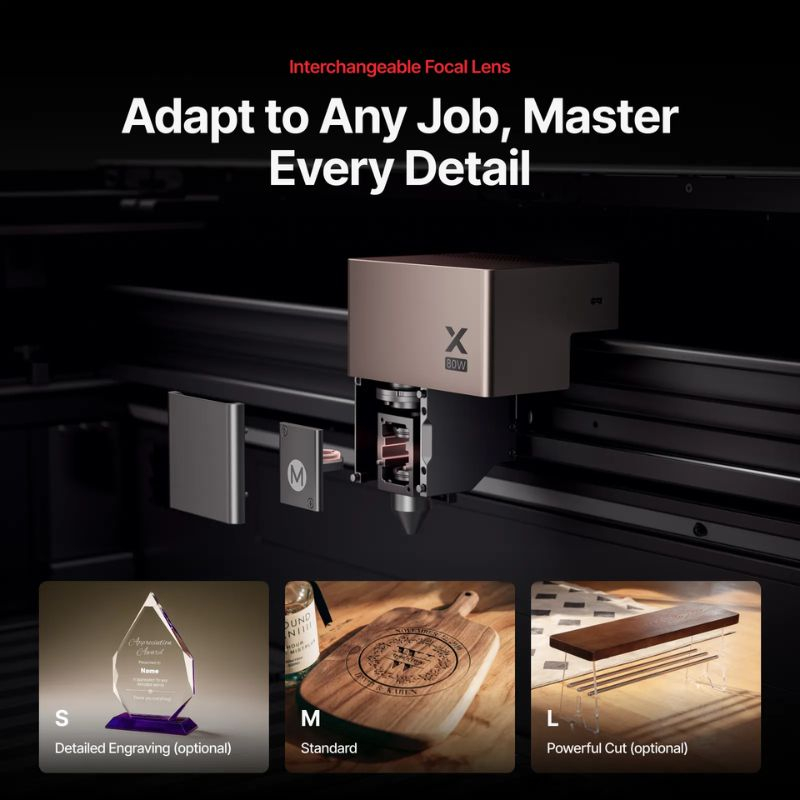

The xTool P3 is an 80W CO₂ laser engraver and cutter designed for professionals, makers, and small businesses. Its large working area (915 × 458 mm) makes it suitable for processing big pieces or handling batch production.

Clean cuts up to 20 mm in solid wood and a speed of 1200 mm/s ensure high productivity and precision. Equipped with autofocus and a dual-camera system with LiDAR, it simplifies positioning and guarantees reliable operation.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The xTool P3 is positioned as a bridge between desktop machines and full industrial laser systems. With 80W of CO2 power, a large working area, and advanced automation features, it is aimed at small businesses, creative studios, and makers seeking productivity and reliability without the need for heavy-duty equipment.

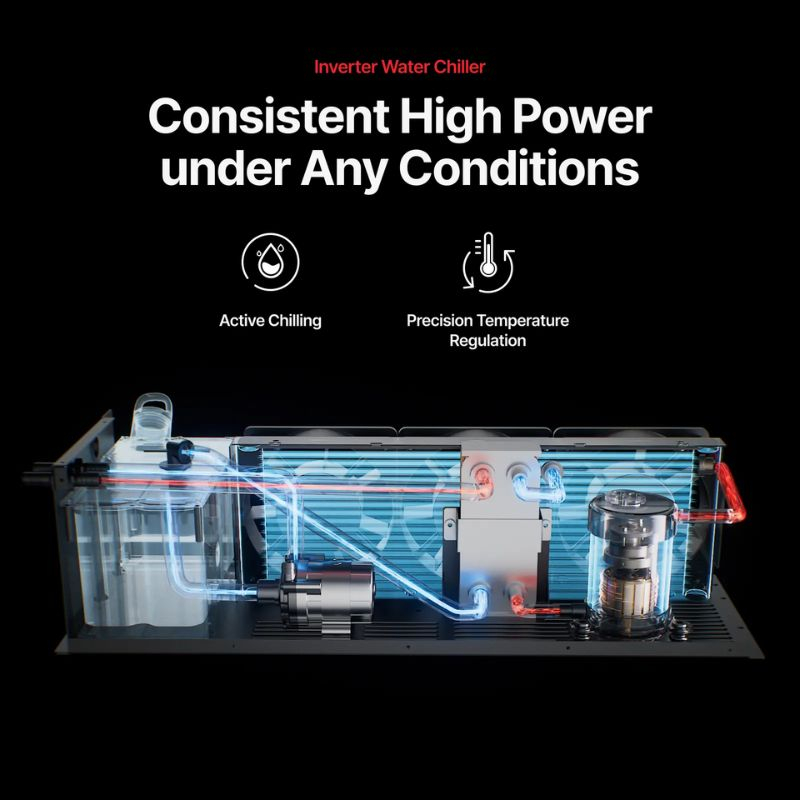

A robust frame ensures precision even at high speeds, while the integrated water-cooled system extends the lifetime of the laser tube. User-friendly software and multiple smart sensors make it easy to use, even in demanding production workflows.

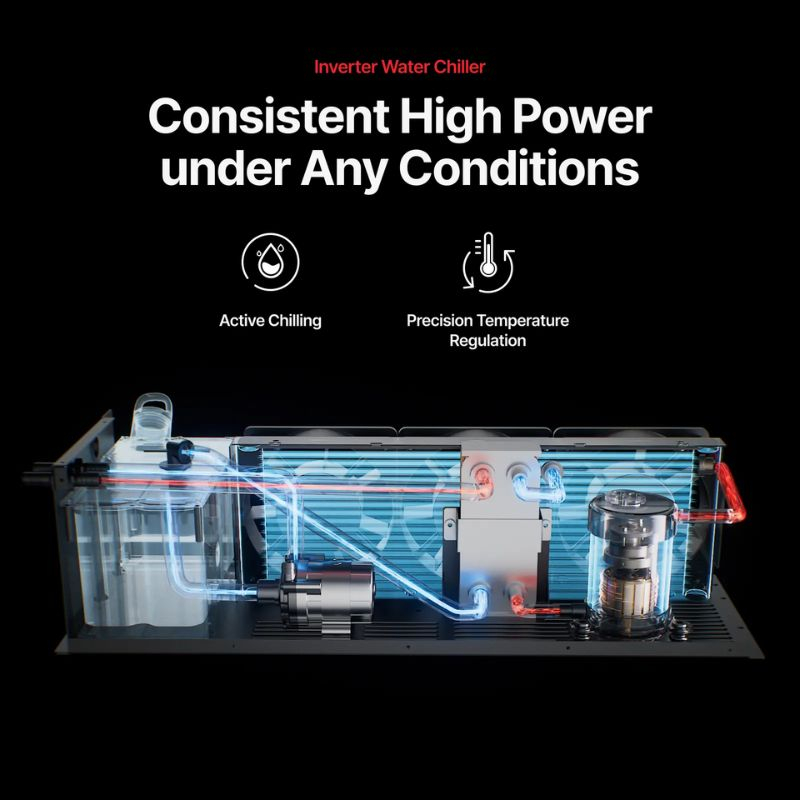

A continuous 80W output is delivered with stability ensured by an integrated inverter chiller.

This allows for long sessions without performance loss.

Capable of cutting up to 20 mm solid wood or 25 mm acrylic in a single pass.

Thinner materials are processed quickly, with no excessive burning and sharp edges maintained.

A 915 × 458 mm workspace provides enough room for large panels, oversized unique pieces, or multiple parts in a single setup.

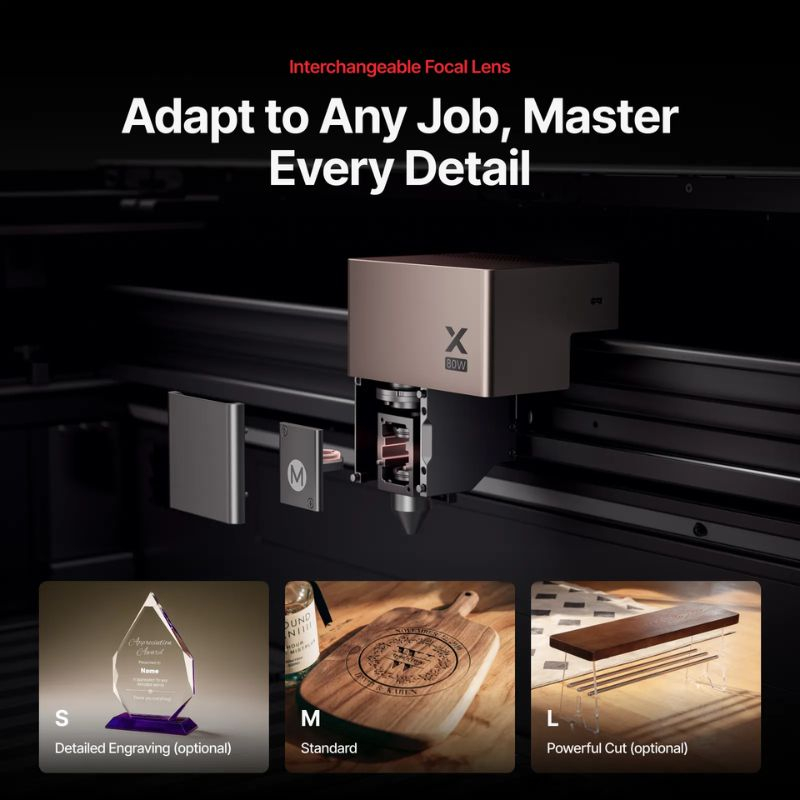

A 5W infrared laser source will soon be available as an option for the xTool P3.

This add-on will enable engraving of materials that CO2 lasers struggle with, such as anodized metals and certain technical plastics.

Powerful motors and a rigid frame enable speeds of up to 1200 mm/s, ensuring high productivity while maintaining fine detail accuracy.

The X-axis acceleration reaches 19,600 mm/s² for rapid movement.

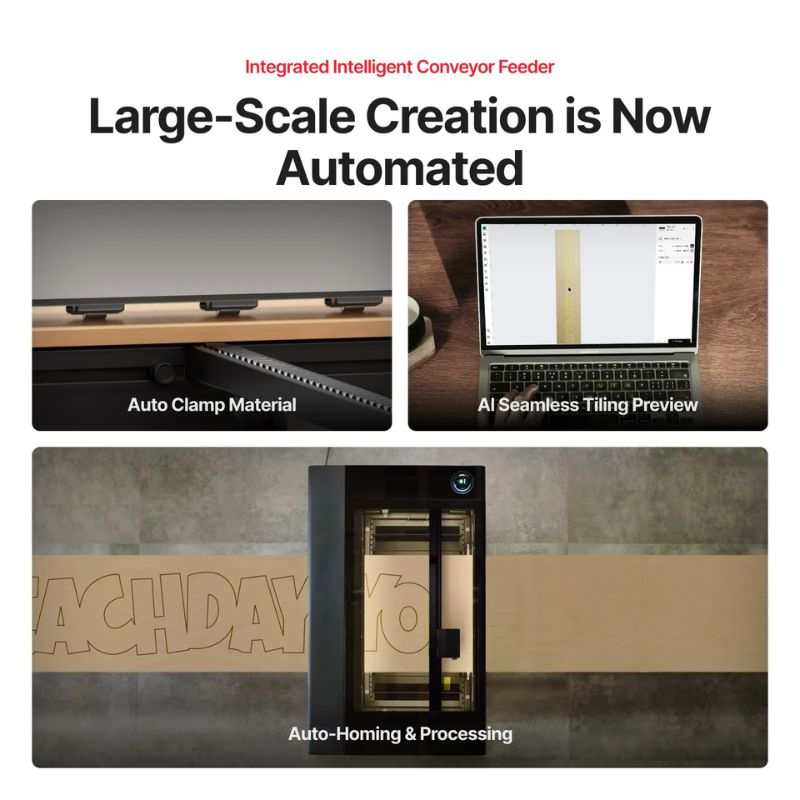

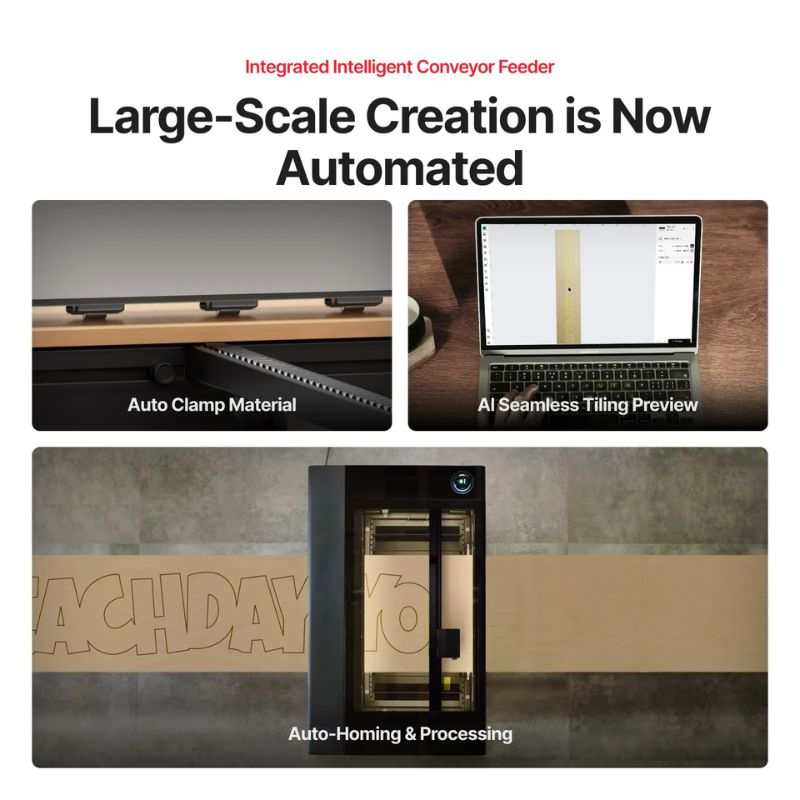

A compatible conveyor is available for automatic material feeding.

Long pieces or roll-fed jobs can be processed continuously, without manual intervention.

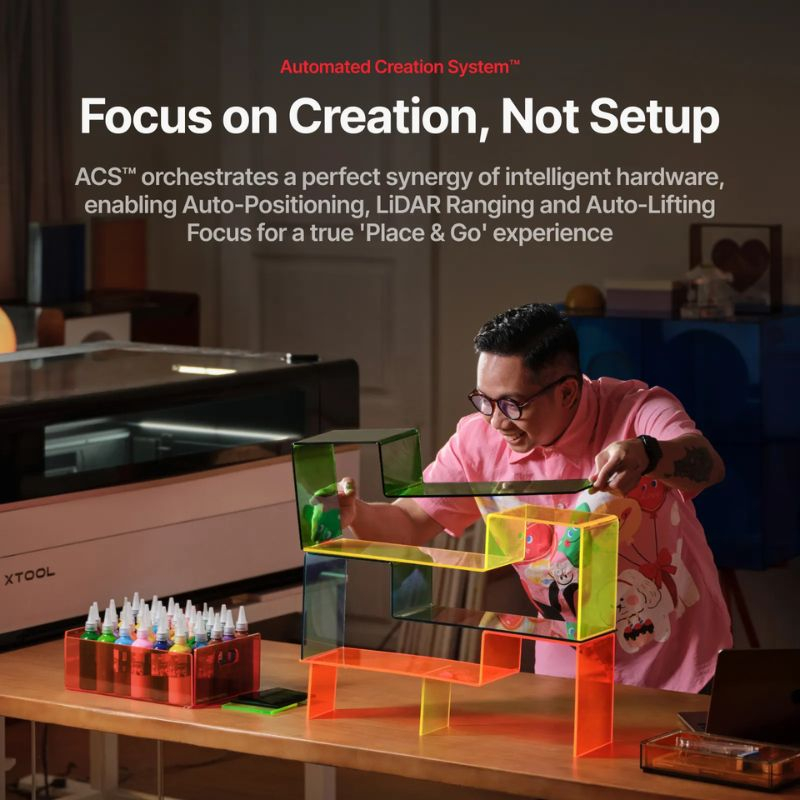

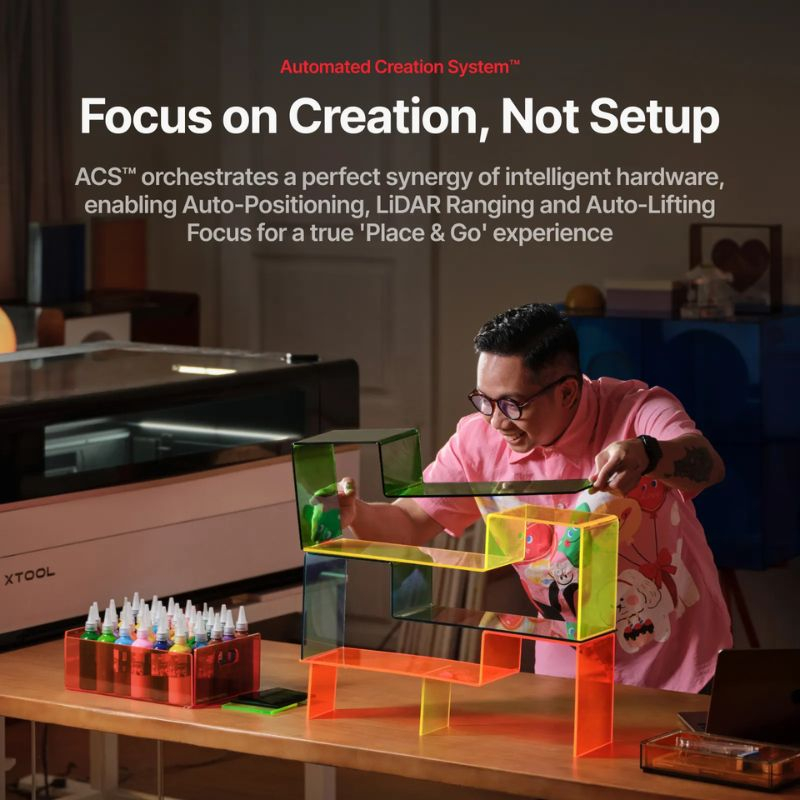

The ACS™ provides a fully automated workflow. Cameras, telemetry, and motion control work together to eliminate tedious manual adjustments.

Positioning, calibration, and focusing are all handled automatically.

A dual-camera vision system combines a 16 MP panoramic camera for distortion-free overviews with a macro camera that reaches 0.02 mm accuracy.

Large panels and miniature parts are both aligned with precision.

The integrated LiDAR system instantly measures distances with precision.

Each material is automatically focused, ensuring consistent cutting and engraving depth with no user input.

The AutoLift base automatically adjusts the working height up to 220 mm, removing the need for manual setup.

Guided by LiDAR measurements, it ensures constant focus, even on taller objects.

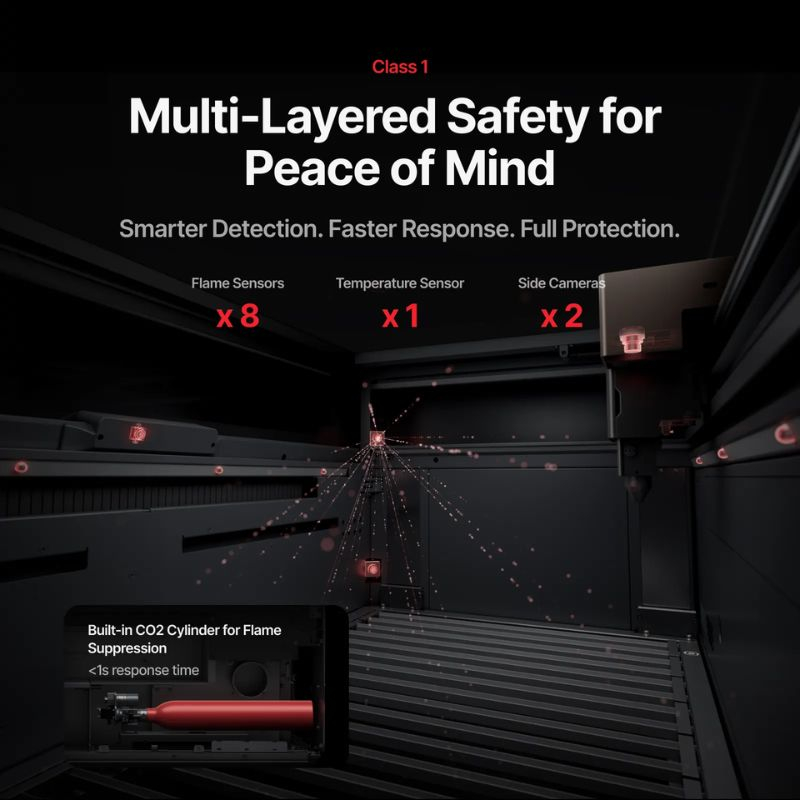

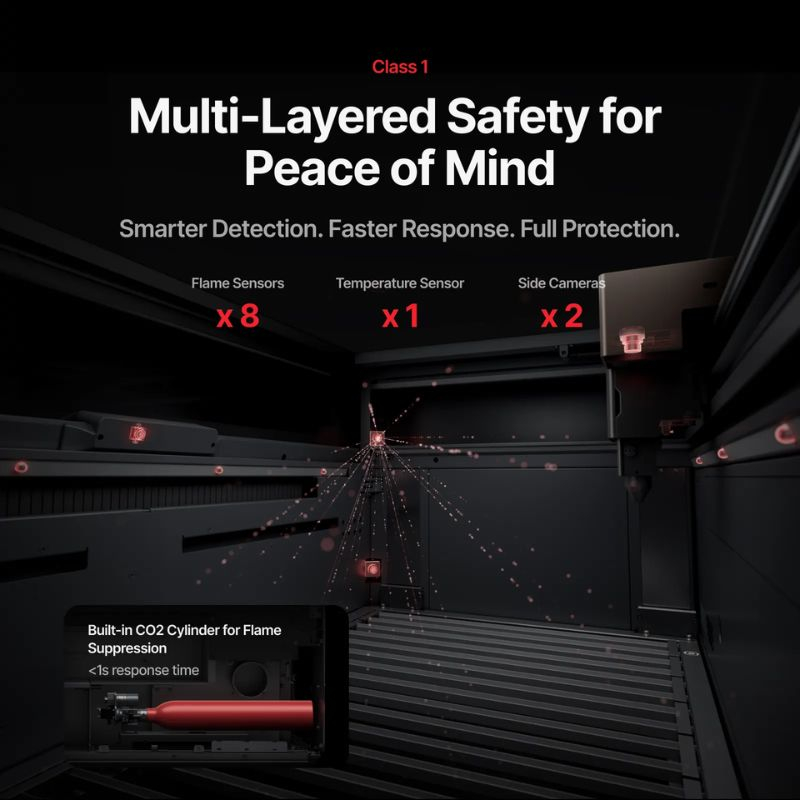

A fully enclosed Class 1 housing includes flame, overheating, and particle detection with an integrated fire protection system.

Automatic shutdown is triggered in case of anomalies to protect the operator.

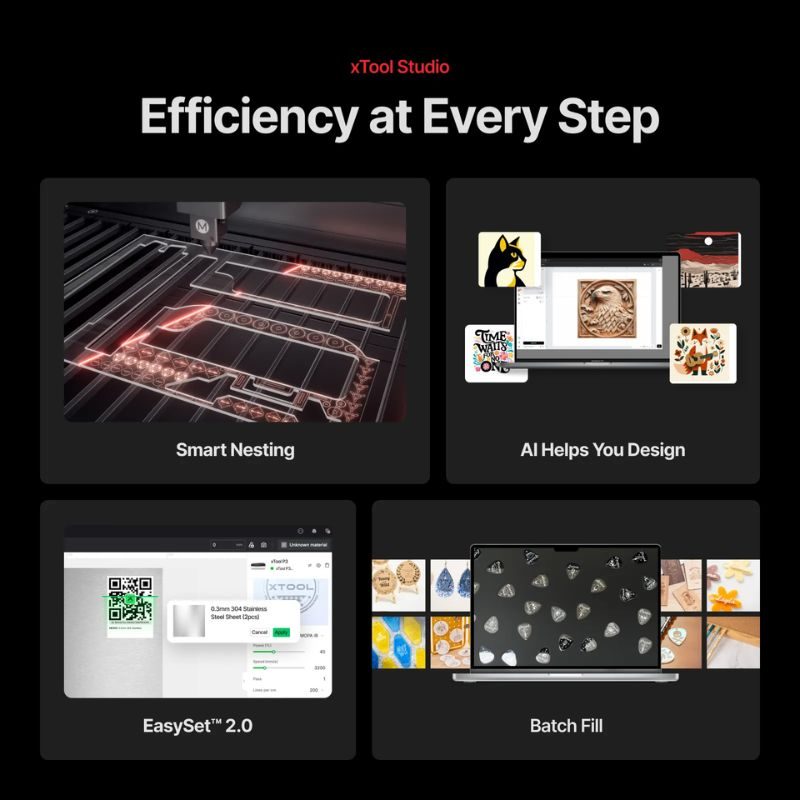

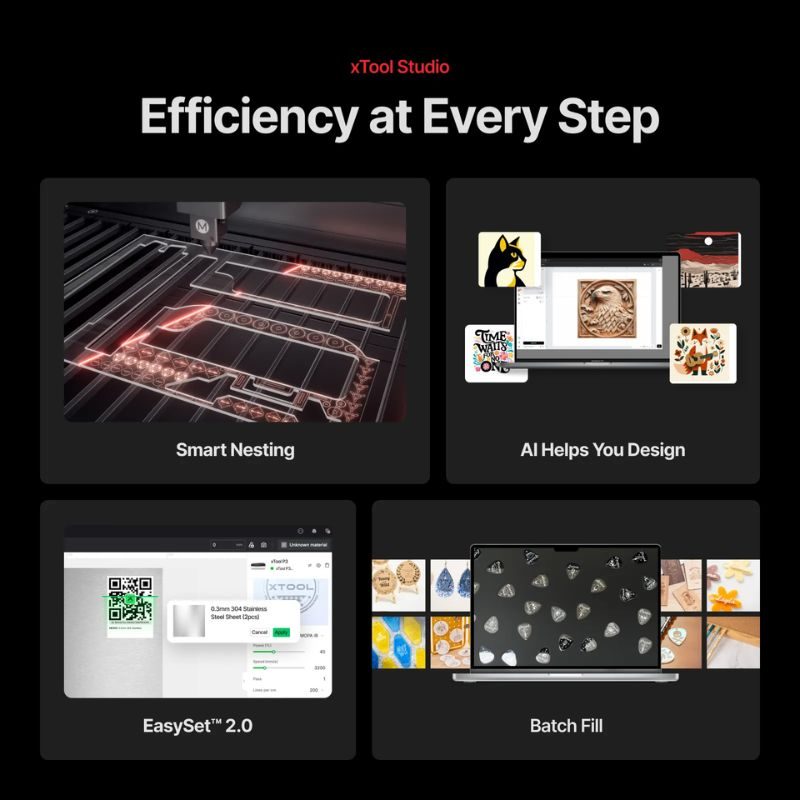

The software includes automatic material recognition via camera, drag-and-drop functions to place designs, and auto-nesting to maximize workspace efficiency.

Repetitive tasks can be streamlined with batch processing, boosting productivity and profitability in production workflows.

The xTool P3 stands out with its 80W CO2 power and large working area, making it an ideal solution for professional workshops and small businesses. Its cutting ability is remarkable, handling up to 20 mm solid wood or 25 mm acrylic in a single pass while maintaining clean, consistent edges.

Its real strength lies in automation: autofocus with the AutoLift base, conveyor for continuous operation, and a vision system (cameras + LiDAR) that makes piece positioning simple. The engraving speed of up to 1200 mm/s is fully usable thanks to a rigid frame that minimizes vibrations.

Designed for smooth and safe production, with Class 1 housing and multiple sensors, the xTool P3 offers a rare balance: a powerful and reliable machine accessible without stepping into expensive industrial equipment.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

1200 mm/s

Specifications for xTool P3

Technology / Product

Machine tools

Software