The Bambu Lab H2S Laser Full Combo 10W is a versatile and high-performance machine that integrates different technologies: multi-color 3D printing, laser engraving and cutting, digital cutting, and drawing.

It combines precision, speed, and reliability, while offering remarkable ease of use thanks to its numerous sensors and automated management systems.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Bambu Lab H2S Laser Full Combo 10W is a true all-in-one digital workshop. Combining high-speed 3D printing, 10W laser engraving and cutting, as well as assisted cutting and plotting tools, it delivers a complete and powerful solution for creators and professionals.

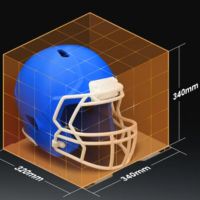

Its built-in intelligence streamlines alignment, calibration, and project management, while its robust design and large build volume (340 x 320 x 340 mm) make it possible to produce ambitious and precise parts.

Designed for professionals and DIY enthusiasts alike, the H2S Laser Full Combo 10W combines productivity, reliability, and safety. With advanced features such as Air Assist, the Bird’s Eye camera, and smart sensors, it ensures consistent quality while simplifying workflows.

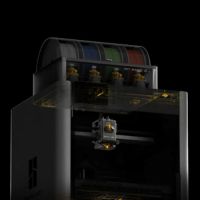

Its compatibility with the AMS 2 Pro unlocks multi-material and multi-color printing, while the laser module expands creative possibilities across a wide range of materials. A complete machine built to innovate without limits.

The Bambu Lab H2S Laser Full Combo 10W features a 10W laser module capable of delivering sharp engravings and cutting plywood up to 5 mm thick.

Its Air Assist system continuously cools the cutting area, minimizing burn marks and enhancing finishing quality.

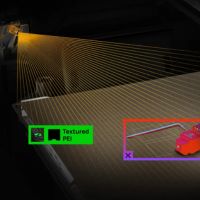

The BirdsEye camera combined with real-time tracking provides positioning accuracy down to 0.3 mm. The Print & Cut feature automatically aligns cutting paths with printed graphics for flawless precision.

Meanwhile, the Auto Arrangement tool optimizes the layout of cut pieces, making use of leftover material and reducing waste.

The H2S Laser Full Combo 10W includes several safety systems: laser-protection windows, a door sensor that instantly shuts down the laser, an emergency stop button, and an audible alarm.

It is also equipped with flame detection sensors that can identify fire hazards and trigger an immediate alert. The chamber is built with fire-resistant materials, ensuring passive protection and reducing risks from high operating temperatures.

Pairing the H2S Laser Full Combo 10W with the AMS 2 Pro allows users to combine rigid and flexible materials in a single print. This makes it possible to create hinges, seals, and complex functional parts that traditional processes cannot achieve.

It also enables alternating between high-performance polymers and standard plastics, reducing costs while reinforcing critical areas.

Multicolor printing management via the AMS 2 Pro makes the process seamless and efficient.

Color transitions are fully automated, enabling the creation of detailed, aesthetic, and personalized models without manual intervention or wasted time.

The Vision Encoder, sold separately, provides ultra-precise calibration with a 5-micron optical system.

It dynamically corrects printhead movements, ensuring dimensional accuracy and consistent quality across the entire build plate.

The Auto Hole/Contour Compensation system minimizes dimensional deviations during printing, delivering fits comparable to machined parts.

This makes mechanical assemblies more reliable and reduces the need for post-processing corrections.

With a build area of 340 × 320 × 340 mm, the H2S Laser Full Combo 10W supports the creation of large-format parts, whether in 3D printing or laser engraving, significantly expanding creative potential.

The printer reaches 350°C at the nozzle and maintains a 65°C heated chamber.

This advanced thermal capacity ensures strong layer adhesion and high-quality prints with technical polymers such as PEEK, PEI, and reinforced nylon.

The next-generation hotend delivers up to 40 mm³/s, ensuring smooth, fast extrusion.

With its clip-on nozzle system, maintenance is quick and tool-free, enabling rapid nozzle swaps in seconds.

The DynaSense extruder uses a precision PMSM motor, capable of analyzing torque and resistance in real time.

It dynamically adjusts filament feeding, detects anomalies, and prevents clogging risks.

The printer includes an AI-powered camera with a macro lens that continuously detects filament deposition issues.

Errors are identified and corrected quickly, reducing print failures and improving reliability.

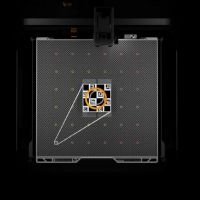

Before every job, the H2S Laser Full Combo 10W performs a full check: build plate inspection, nozzle recognition, and working condition analysis, ensuring optimal preparation.

A network of 23 sensors monitors filament parameters: speed, tension, precise positioning, thermal conditions, and extrusion pressure.

This advanced management, enabled by the AMS 2 Pro, anticipates issues and increases print success rates.

A closed-loop system constantly monitors heating elements, automatically adjusting parameters to ensure stability and extend component lifespan.

The Adaptive Airflow system intelligently regulates internal and external circulation via adjustable vents.

It ensures effective ventilation, filters fumes, and maintains optimal conditions for both laser engraving and 3D printing.

The H2S Laser Full Combo easily connects via Wi-Fi to your computer or smartphone.

The Bambu Lab app lets you start, monitor, and manage prints remotely, giving you full control and flexibility over your workflow.

The Bambu Studio slicing software is fully optimized to leverage the features of the H2S Laser Full Combo.

It automatically adapts settings according to filament type, speed, and precision needs, ensuring optimal results from the very first print.

The Bambu Lab H2S Laser Full Combo 10W stands out as a true all-in-one solution, bringing together high-performance 3D printing, laser engraving, digital cutting, and plotting. Its versatility makes it an ideal choice for both passionate makers and demanding professionals.

The 10W blue laser delivers sharp engravings and clean cuts on wood, leather, opaque acrylic, and more, while the generous build volume (340 × 320 × 340 mm) supports large-scale projects. With its advanced technologies, precision is consistent, and print failures are minimized.

The H2S Laser Full Combo 10W also integrates Bambu Lab’s key innovations: smart sensors, real-time camera monitoring, automatic calibration, and AMS 2 Pro compatibility for multi-material and multi-color projects. Reliability, safety, and automation make it a complete machine capable of turning any idea into a finished creation.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

340 x 320 x 340 mm

10 microns

1000 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Composites, PVA, ASA, PP, PLA-CF, PET-CF, PA-CF

Specifications for Bambu Lab H2S Laser Full Combo 10W

Technology / Product

Extrusion

Heated bed

Machine tools

Specific equipment

Software

Installation / Prerequisites