- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

-

- 3D printers

- 3D Filaments

-

3D resins

-

-

3D-Scanner

-

-

Machine tools

-

-

Accessories

-

-

-

Transparent DIY enclosure Creality Ender-3 V3 SE, Ender-3 S, Ender-3 S1 Pro

Regular price €115.00 Price €92.00

-

Spare parts

-

- 3D Packs

- Refurbished

Filter By

Price

-

€32.00 - €35.00

- 🎯 Services dedicated to professionals

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14-day return

Food contact

Active filters

Food contact

Filaments that comply with the American FDA or European CE food-grade standards allow for direct contact of the specified filaments with food. Intrinsically, some materials such as PETG or PP have food-grade properties. Some filament manufacturers have maintained this characteristic by producing according to these standards.

As with any application in the food sector, these standards are valid for the raw filament on the spool. The transformation process through 3D printing automatically transfers responsibility.

Indeed, users of 3D printed parts that come into contact with food must take responsibility for adhering to the standard practices of this environment. As long as your entire process follows the best practices already established in the food industry, there is no risk of contamination or pollution.

In practice, using food-safe (FDA) filament should go hand in hand with a dedicated 3D printer. Using multiple materials on the same machine can lead to contamination, even if your filament is food-safe.

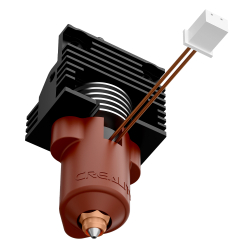

It is essential to ensure that your entire extrusion system is clean — from the drive mechanism, through the Bowden tubes, to the nozzle. In this context, it is recommended to use a steel nozzle instead of the traditional brass one.

3D filaments suitable for food contact are often technically advanced and mechanically strong. PETG is rigid yet durable, while PP is semi-flexible, tear-resistant, and bendable. These PP filaments are commonly used in bottles and packaging, as they provide sealing and impact resistance even in thin objects.

How to choose a food-safe filament?

Despite some materials having inherent food-safe properties, it is important to check the technical or safety data sheets for FDA and/or CE compliance.

Some manufacturers guarantee continued food contact compliance because they commit to maintaining good manufacturing practices.

Remember that filament production itself is already a transformation process. The same applies to you as a new processor of this pre-shaped raw material.

Which food-contact (FDA) filament to choose?

We strongly recommend focusing on European-made filaments for these applications, ideally certified with the CE mark in addition to FDA. Otherwise, color and available diameter may also influence your choice.