- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

-

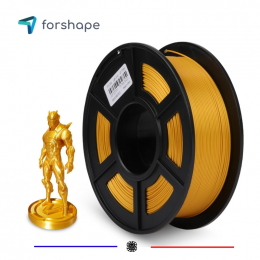

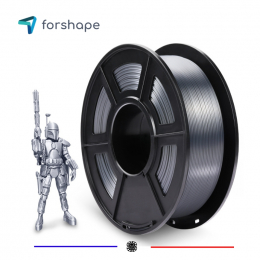

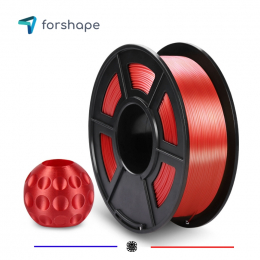

Silk & Silk PLA Filament

The Silk PLA filament provides a glossy and satin finish, perfect for decorative prints. Easy to print, it retains the benefits of standard PLA while enhancing the parts with a silky and uniform visual rendering, without post-processing.

Active filters

Polylite Dual Silk PLA Aubergine Lime-Magenta - 1.75mm - 1 kg

- -20%

Polylite Dual Silk PLA Banquet Gold-Magenta - 1.75mm - 1 kg

- -20%

Polylite Dual Silk PLA Beluga Silver-Blue - 1.75mm - 1 kg

- -20%

Polylite Dual Silk PLA Chameleon Yellow-Blue - 1.75mm - 1 kg

- -20%

Polylite Dual Silk PLA Sovereign Gold-Purple - 1.75mm - 1 kg

- -20%

- -20%

Silk & Silk PLA Filament

The Silk PLA filament, sometimes referred to as Silk PLA, stands out for its unique visual finish: a satin shine and a surface smoothness rarely achieved with standard materials. Its composition is based on a PLA base enriched with additives that modify the diffusion of light on the surface of the piece, thus creating this characteristic "silk" effect.

Technical Properties

Superior aesthetic finish: Silk PLA is perfectly suited for the creation of presentation objects, figurines, trophies or decorative elements. Its shine partially masks the printing layers, making the surface visually smoother.

Printing ease: It prints with the simplicity of a standard filament, at low temperature (190–220 °C), without the need for a high heated bed.

Good inter-layer adhesion: The fluidity of the material promotes a solid and regular bond, reducing the risks of delamination.

Universal compatibility: It is suitable for the majority of printers, without the need for a closed enclosure or specific conditions.

Limits and Precautions

Reduced mechanical resistance: Silk PLA is primarily an aesthetic material. Its slightly modified structure for shine makes it less rigid than standard PLA.

Sensitive to heat: It softens beyond 55–60 °C; therefore, it is not recommended for parts exposed to high temperatures.

Bed adhesion: The very smooth surface may require the use of an adhesive or bed-tape to ensure the hold of the first layer.

Printing Tips

- Nozzle temperature: 200 – 215 °C depending on the brand and shade.

- Bed: 50–60 °C recommended, but not mandatory.

- Speed: between 40 and 60 mm/s to maintain the shine.

- Cooling: moderate to high to avoid stringing and enhance the sharpness of the contours.

- Storage: Keep away from moisture, as Silk PLA is sensitive to water absorption.

Why choose Silk PLA?

The Silk PLA filament is primarily chosen for its aesthetic value. It allows for the production of exhibition objects, decorative items or visual communication pieces with a professional finish, without the need for painting or polishing. Easy to handle and compatible with most printers, it is an excellent alternative for those looking to enhance their prints with a high-end look and a silky finish.