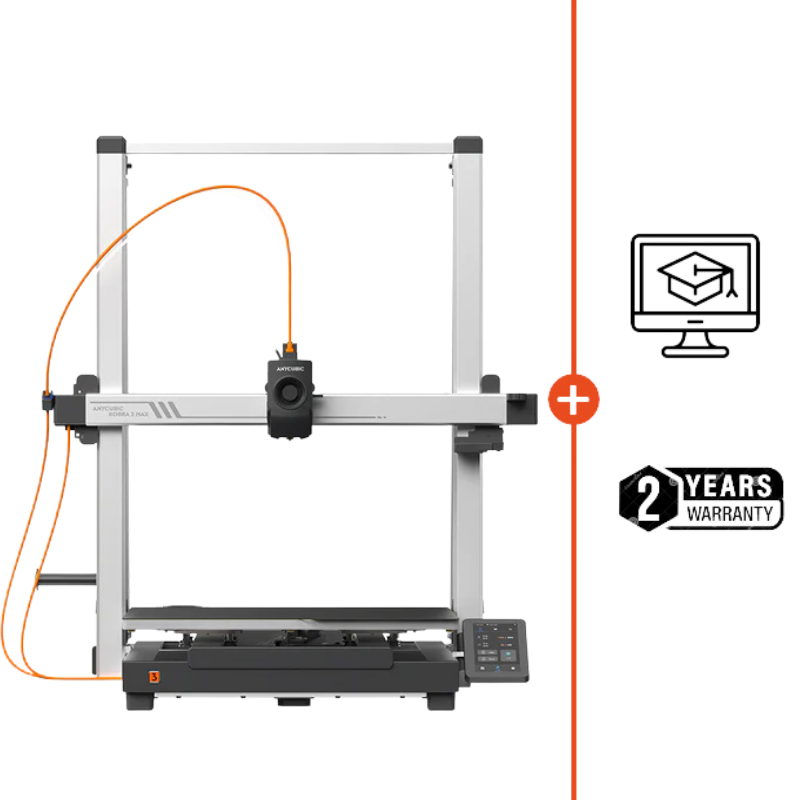

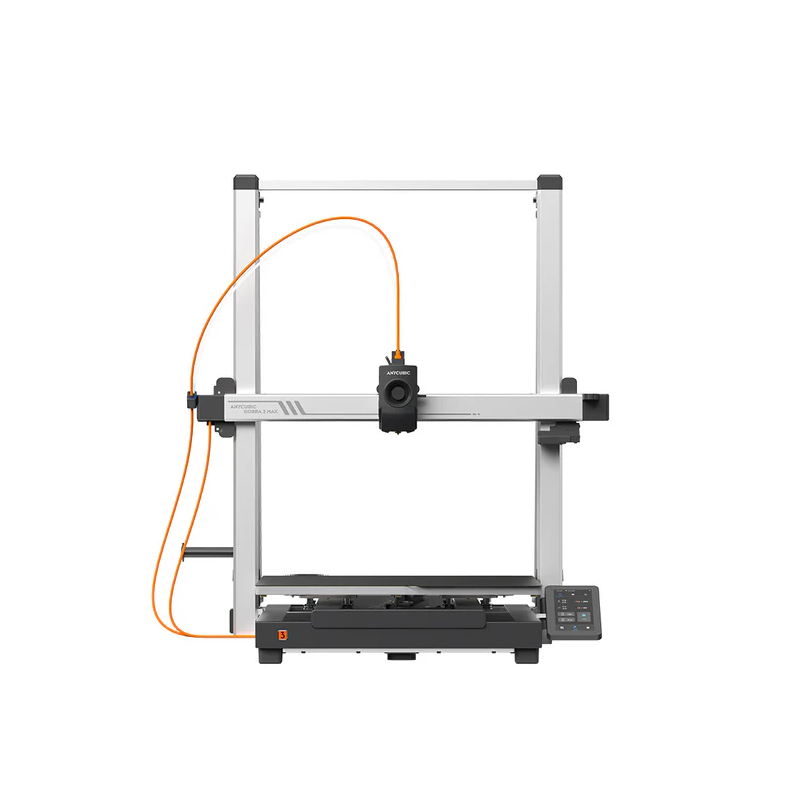

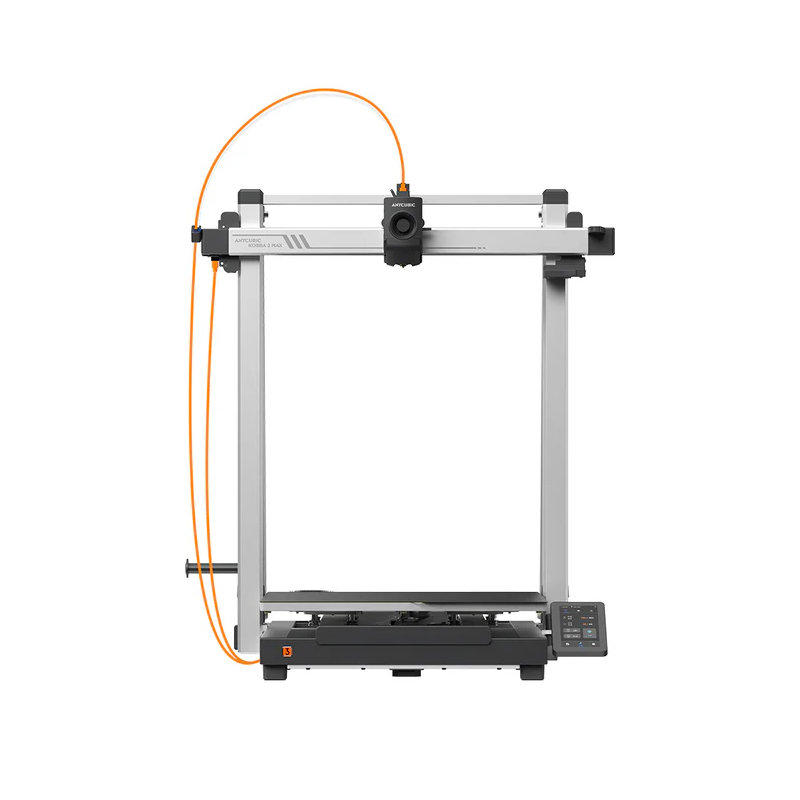

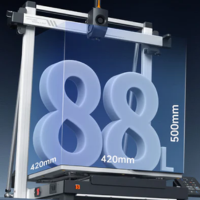

Anycubic Kobra 3 Max is a high-speed, large-format 3D printer, designed for those seeking both precision and efficiency. With an impressive print volume of 420 x 420 x 500 mm, it enables large projects to be completed in a single print.

Automatic leveling, anti-shift motors, and intelligent filament management ensure easy operation and reliable performance.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

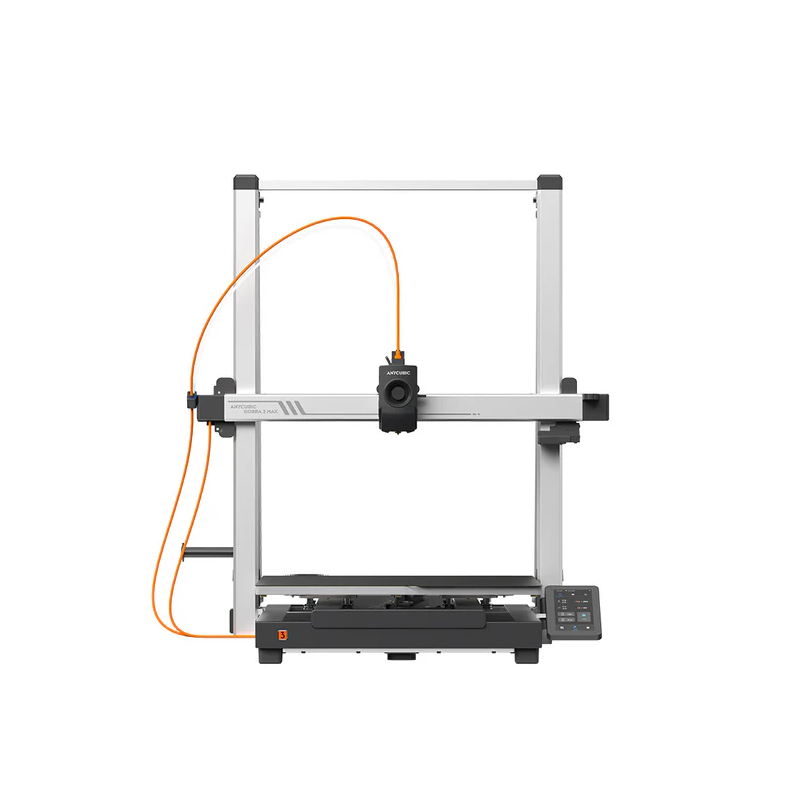

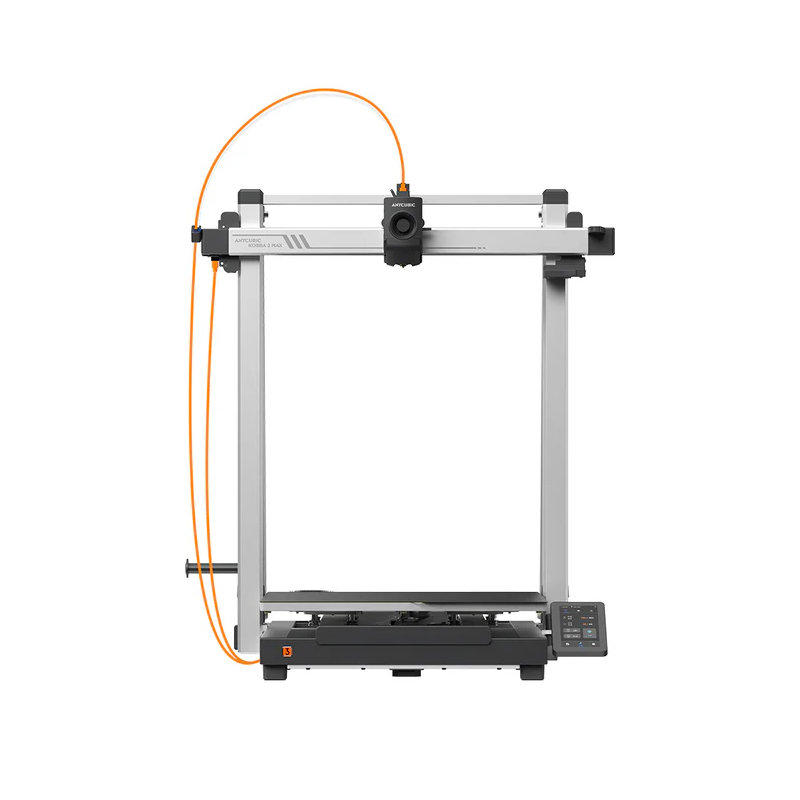

The Anycubic Kobra 3 Max is designed for projects that cannot compromise on build volume or precision. A 420×420×500 mm platform enables the printing of large-scale objects such as full prototypes, mechanical components, or decorative elements in one go. Every component is built for reliability: LeviQ 3.0 auto-leveling, anti-skip motor, and advanced filament management. Time efficiency and consistent results are ensured alongside surface quality and dimensional accuracy.

With 420×420×500 mm, large and tall models can be printed in a single run. This eliminates assembly steps, reduces adjustments, and saves time on repeated productions.

.png)

A maximum speed of 600 mm/s allows simple prints or infill to be completed much faster. In practice, a recommended 300 mm/s ensures the right balance between speed, quality, and stability.

.png)

LeviQ 3.0 auto-leveling with Z-offset, anti-skip motors on the Y-axis, and filament features such as anti-tangle and auto-replenishment minimize manual intervention and production downtime.

.png)

The 800 W AC bed heats from 25 °C to 60 °C in ~125 seconds, speeding up preparation for large parts while ensuring uniform temperature.

.png)

The standard 0.4 mm nozzle is included, while 0.2 / 0.6 / 0.8 mm options are supported. This flexibility allows for fine detail or faster extrusion depending on project needs.

.png)

Supports PLA, PETG, ABS, and TPU with 1.75 mm filament. Suitable for functional parts, mechanically stressed prototypes, or objects requiring flexibility.

.png)

With a max acceleration of 10,000 mm/s², inertia control and resonance compensation (“input shaping”) reduce vibration and oscillation artifacts on large movements.

.png)

The internal Kobra OS is optimized for this machine. A color touchscreen simplifies local adjustments. The “Anycubic Slicer Next” and mobile app offer smooth integration for file transfer, monitoring, and multicolor management via ACE Pro.

The supplied Anycubic Slicer Next software and mobile app enable remote control and advanced preparation. Features include color change management (purge objects), preview, advanced print parameters, and in-print monitoring. Material profiles are easily accessible even for beginners, while still allowing expert-level fine tuning.

After many hours of printing, the Kobra 3 Max proves outstanding for large builds. Elements taller than 40 cm required no assembly. Once properly leveled, the bed stability is excellent, although the weight and vibrations require a sturdy setup. Overall, it stands out among large-format 3D printers for its price-to-volume ratio, especially valuable in prototyping workshops and small-batch production.

420 x 420 x 500 mm

100 microns

600 mm/s

PLA, ABS , PETG, Flexible

Specifications for Anycubic Kobra 3 Max

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites