The Raise3D Pro3 3D printer follows in the footsteps of the Pro2 with many new features, including a system of independent extrusion heads, automatic bed leveling, and an integrated Air Manager for controlling airflow and temperature inside the 3D printer.

The Raise3D Pro3 is designed for product development, rapid prototyping, and form validation. It can also be used for production of finished parts and small series. Its material compatibility allows printing parts with very interesting mechanical properties.

This 3D printer fits perfectly into your production cycles and will make you more agile. Its integrated ecosystem allows you to manage the manufacturing of your 3D parts in real time.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

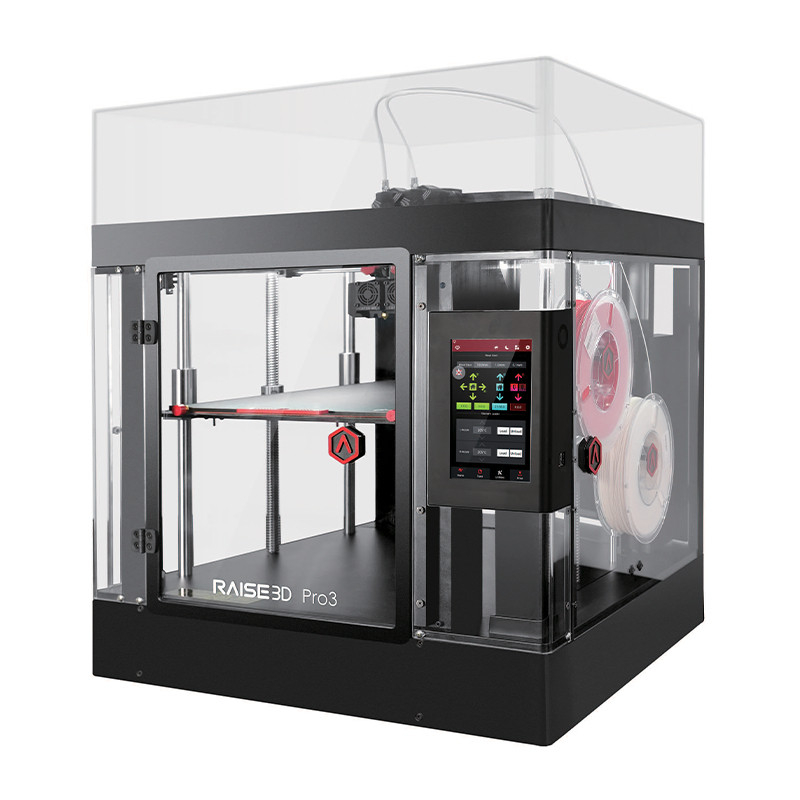

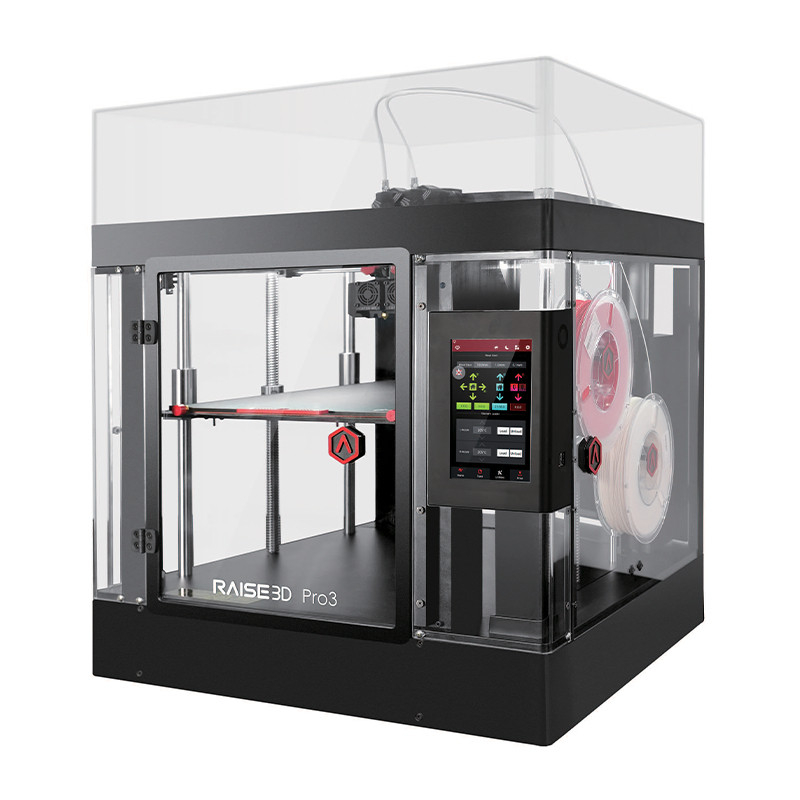

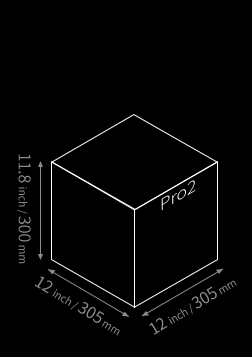

The Raise3D Pro3 is a large-format 3D printer offering a fully usable build volume of up to 300x300x300mm. Its new system of interchangeable hotends simplifies maintenance of your printer and allows you to switch materials very quickly to start new prints.

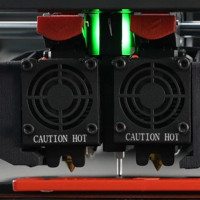

This dual extrusion 3D printer features a robust and sturdy frame that provides high stability during printing. This ensures high-quality parts thanks to its exceptional precision.

Its large build volume and reliability make the Raise3D Pro3 a high-performance and professional 3D printer. Its broad compatibility with standard and technical materials allows you to print parts for varied applications and demanding technical requirements.

The Raise3D Pro3 adapts well to your workspace and meets your technical requirements. With numerous latest innovations from the brand, it promises to tackle your technical challenges.

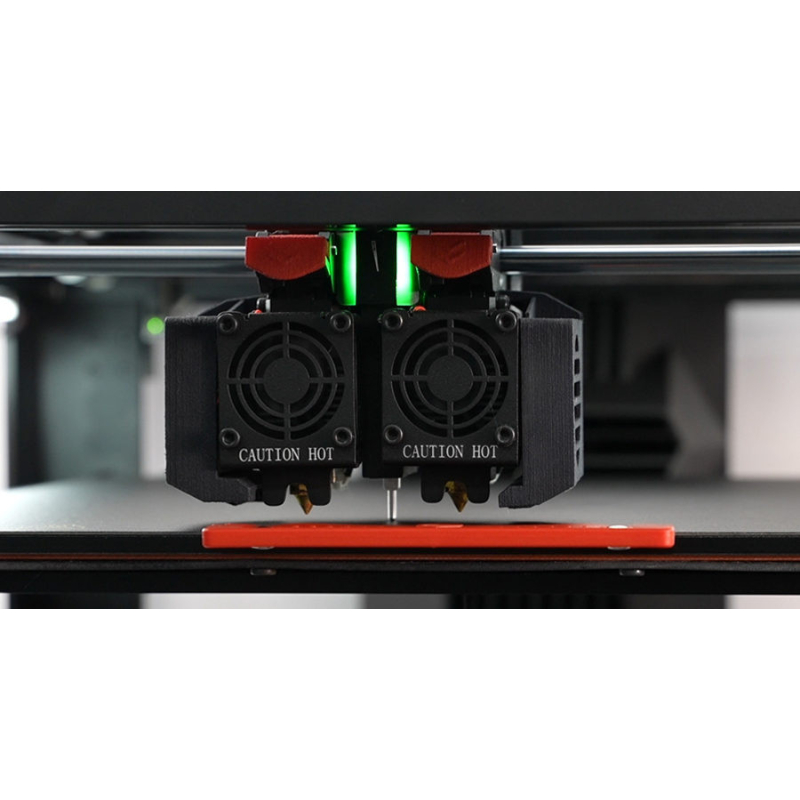

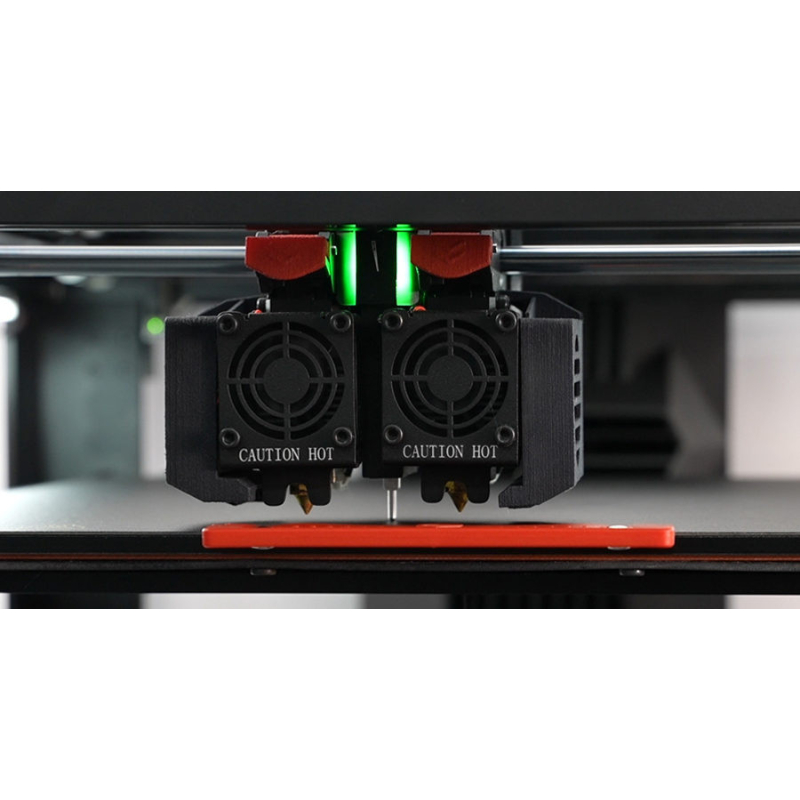

The Raise3D Pro3 comes with independent print heads that allow you to quickly change hotends. These detachable hotends greatly simplify machine maintenance and let you switch print heads quickly depending on materials or print profiles.

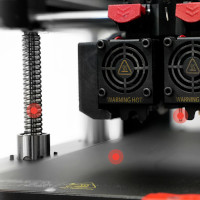

The Raise3D Pro3 includes an automatic leveling system for its aluminum heated bed. This system adjusts the distance between the nozzle and the bed to optimize calibration, improving adhesion for your prints.

The Air Flow Manager is located at the back of the Raise3D Pro3. It optimizes air circulation and dissipation during 3D printing and filters fine particles through its integrated HEPA filter, making your workspace safer.

Safety is a key feature of the Raise3D Pro3. Its door open detector automatically pauses printing when a door is opened, ensuring your team works in a protected environment.

Like its smaller sibling (Pro2 series), the Raise3D Pro3 offers advanced and innovative features. In addition to new features, it retains the proven advantages and technologies of the brand.

Alongside these innovations, it inherits the traditional benefits of the Pro2 series, features tested by a large professional community.

The dual direct drive extrusion allows printing technical materials, including flexible filaments, while maintaining high quality and precision for your 3D prints.

No more cutting parts into pieces — print them entirely thanks to the large format of the Raise3D Pro3. The aluminum bed also allows printing multiple parts in a single print for small series production.

The reinforced Z-axis enhances precision when printing large parts. The stronger and sturdier the printer, the lower the risk of failed prints. This highly durable machine meets demanding production requirements.

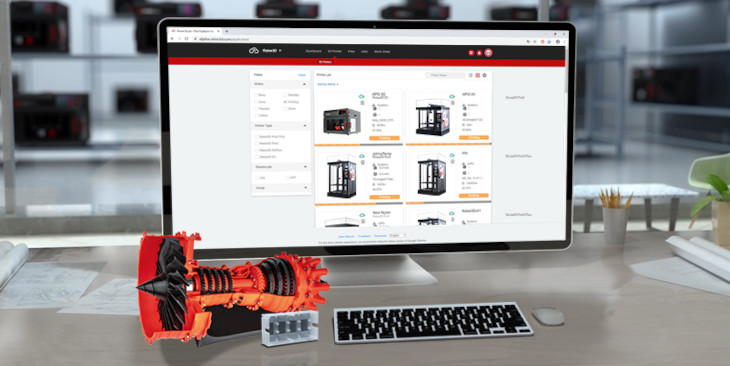

Raise3D offers an integrated ecosystem with software and tools, supporting its 3D printers and community. The Raise3D software suite includes the globally known slicer IdeaMaker, print management software RaiseCloud, and the IdeaMaker Library of files and profiles.

IdeaMaker and its profile library provide a simple and efficient way to prepare and slice your 3D prints. Unique features like applying textures on models are included.

RaiseCloud allows you to connect printers to a central management point and control them easily. Your teams remain agile and flexible.

With features like dual extrusion, direct drive, flexible bed, and Air Flow Manager, the Raise3D Pro3 can print any material extrudable at temperatures up to 300℃.

The direct drive technology allows easy printing of TPU and other flexible materials, useful for professionals and functional prototypes.

Other materials, such as reinforced filaments, ABS, and nylon, allow printing parts with specific mechanical and thermal resistance for different environments. The Raise3D Pro3 is designed to handle these advanced materials effectively.

The Raise3D Pro3 comes with the full Raise3D ecosystem, including slicing and printer/farm management software. It also provides a range of ergonomic components for an improved user experience.

The flexible bed makes part removal easier. Simply bend or twist it slightly to release prints. No spatulas or cutters needed — users stay safe.

The Pro3 features a 7-inch touchscreen for easy printer management and maintenance. Wifi connectivity allows simple network integration.

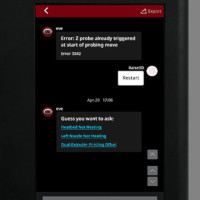

EVE is a unique feature that interacts with your Raise3D Pro3 to guide, advise, and assist in resolving errors or misconfigurations that could affect print quality.

The built-in camera lets you monitor and control your printer remotely via Wifi and RaiseCloud. You can also create timelapses of your prints easily.

The Raise3D Pro3 is designed for professionals and industry. It features high-performance components and functions for demanding users.

The aluminum bed remains flat and adjustable. Combined with the flexible surface and automatic leveling, it ensures perfect print adhesion.

The Pro3 can resume printing after power interruptions, ensuring long prints are not wasted.

From functional rapid prototyping to finished parts and small series production, the Raise3D Pro3 supports industrial professionals in optimizing design and production processes.

Prototyping is critical in product design. Additive manufacturing reduces design stages to just a few hours, delivering functional and visual prototypes efficiently.

3D printing allows production of small series without costly molds, reducing costs and constraints and enabling quick small-scale manufacturing.

Need custom tools, protective covers, or spare parts? Additive manufacturing enables agility and flexibility for rapid development while saving time and costs.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

300 x 300 x 300 mm

10 microns

150 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Filament Support, Composites, PVA, HIPS, ASA, PP

Specifications for Raise3D Pro3

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites