Ultracur3D ST45 is a high-quality Resin that meets the requirements of functional applications with high precision, mechanical strength, and impact resistance.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Ultracur3D resins developed by BASF's Forward AM division are photo-reactive urethane resins designed for DLP/LCD 3D printers.

The ST45 series is the most robust and solid, suitable for demanding applications that require rigidity, impact resistance, and durability.

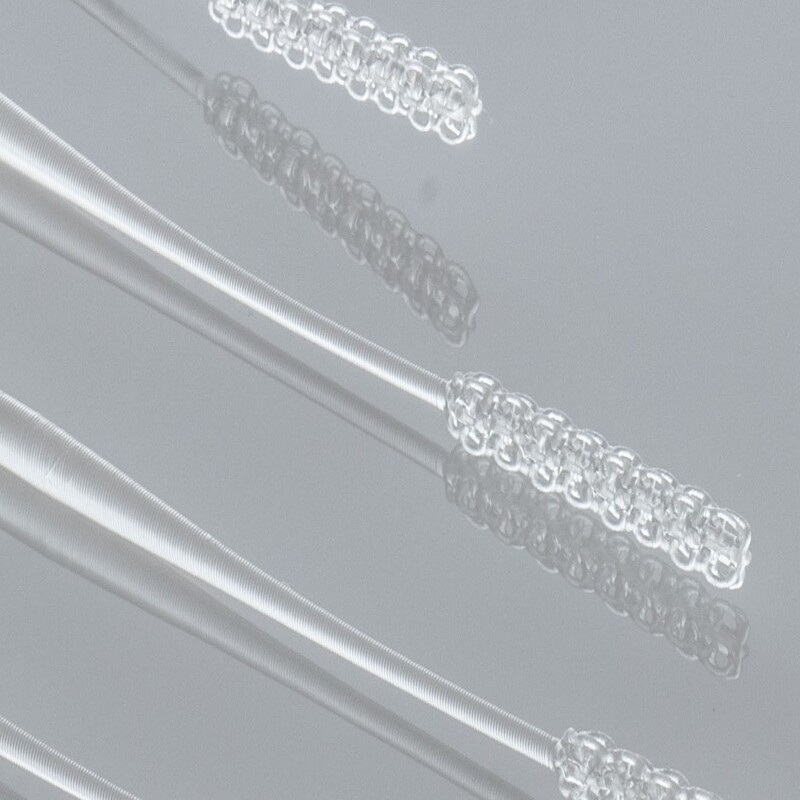

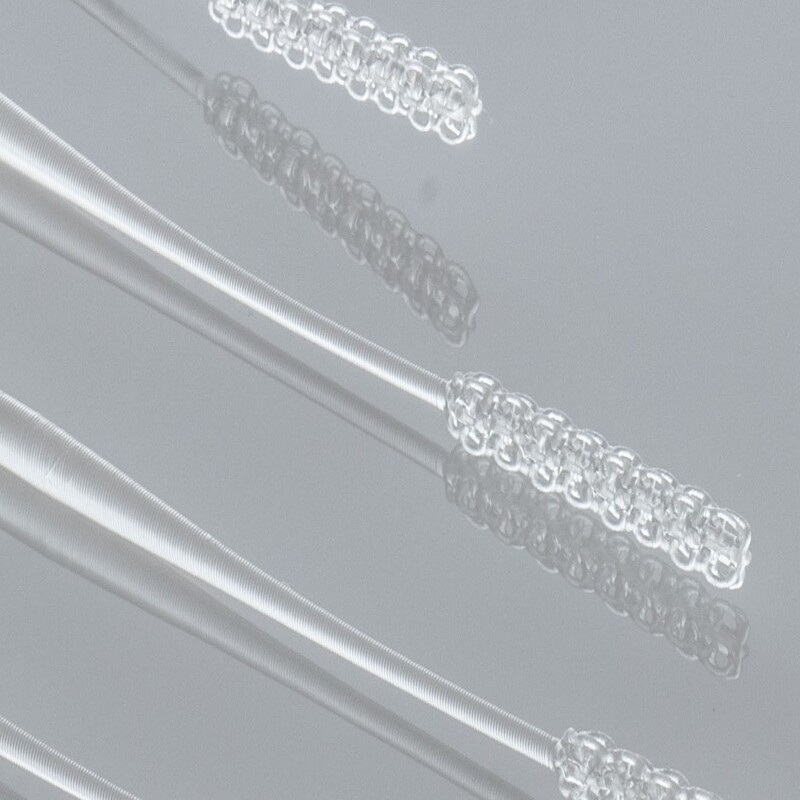

The ST45 Tough resin is recommended for its accuracy, stability, and attractive visual appearance.

Available in a translucent version, the BASF ST45 resin offers the highest rigidity and increased heat resistance.

The ST resins offer the best finish in the Ultracur3D range. They are specially designed for detailed printing and provide good long-term UV stability.

Accelerate your design iterations and reduce development costs with the Tough Ultracur3D ST45 range.

Mechanical strength: Rigid and solid, this photo-reactive ST45 resin provides the highest flexural resistance and the best heat resistance.

Durability: The Ultracur3D ST45 urethane resin is technical and long-lasting. Resistant to prolonged stress, it is particularly suitable for precise parts requiring high mechanical strength.

Precision: Urethane resins deliver maximum dimensional accuracy and stability. Printing accuracy and speed depend on the printer used, but the versatility and quality of these professional 3D resins make them suitable for both simple and advanced applications and technologies.

Ultracur3D resins are sensitive to light, so they must be protected from UV rays when not protected by the printer’s filtering enclosure. Always wear gloves when handling.

Shake the bottle well before use to mix the pigments and achieve good homogeneity. After pouring into the vat, allow a few minutes for bubbles to dissipate.

To determine the proper exposure time for your 3D printer, feel free to consult our community.

Don’t forget to clean your part with IPA alcohol or a suitable cleaner to remove uncured resin and achieve a uniform finish. Finally, complete the post-processing with a UV chamber curing cycle (20 minutes) to obtain the best performance.

Specifications for Resin Ultracur3D® ST 45 BASF - 1000 ml

Technology / Product

Technical values

Polymerization / Resin

Specific equipment