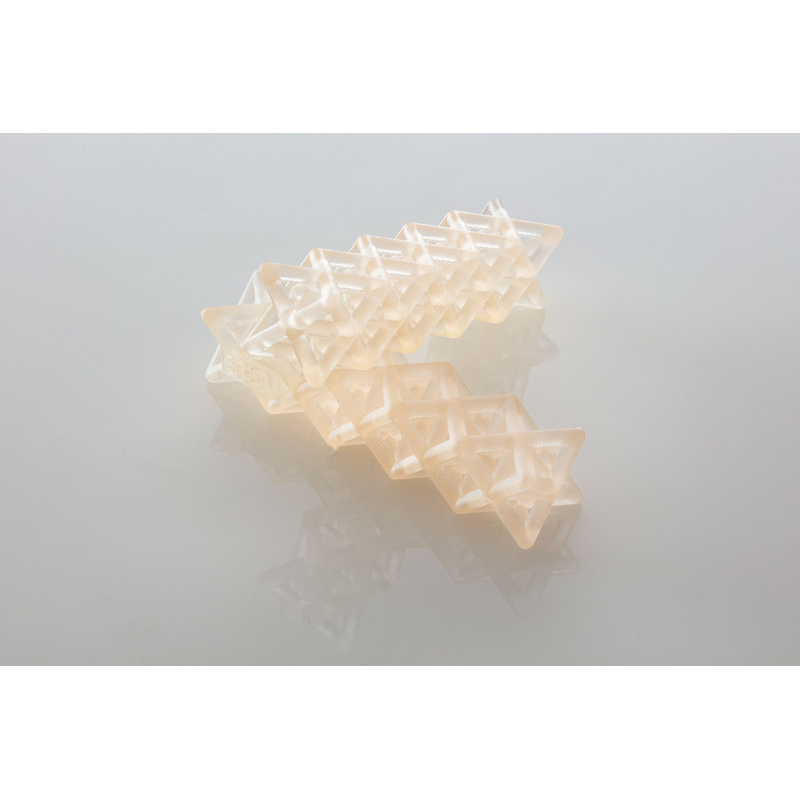

Ultracur3D® RG 50 is a medium-viscosity, highly reactive urethane photopolymer designed for rigid applications.

It offers very high printing precision, low polymerization shrinkage, and good temperature stability, making it ideal for 3D printing high-performance functional parts. Prints can be washed with water after finishing - no chemicals are required.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

BASF resins are photosensitive resins developed for DLP/LCD and MSLA 3D printers.

The RG series is the stiffest and hardest resin range, suitable for the most demanding applications that require high rigidity without deformation.

RG resins have the highest flexural modulus in the Ultracur3D range and the highest thermal stability. They are specifically designed to provide tensile strength and top-level rigidity, as well as high printing accuracy with low shrinkage. Prints made with RG resin have low water absorption and are easy to polish, which accelerates design iterations and reduces development costs.

High rigidity: Ultracur3D RG50 from BASF offers an excellent balance of strength and stiffness. With high flexural modulus and tensile strength, this RG50 resin provides excellent operational stability due to low shrinkage. It delivers useful performance for prototyping, functional parts, or other demanding applications.

Low deformation: Ultracur3D RG50 urethane resins are highly resistant to tension and bending, with a maximum elongation of 4% and very low water absorption. It is also the hardest resin in the range.

Water resistance (cleaning): RG50 resins are very insensitive to water and can be used in humid environments without losing performance or dimensional accuracy. Another advantage is that water can be used to clean your parts.

Ultracur3D RG50 resins are photosensitive and UV-sensitive. Protect them from light once opened and store them away from light. It is recommended to wear gloves when handling the resin.

Shake the resin bottle well before use and let it rest a few minutes after filling your print vat (allow bubbles to dissipate). To determine the optimal exposure settings for your 3D printer with RG50 resin, consult our dedicated community articles.

After cleaning with alcohol or water and brief drying, complete post-processing by passing the part through a UV curing chamber to achieve the specified performance (about 20 minutes depending on size and thickness).

Specifications for Ultracur3D® RG 50 BASF - 1000 ml

Technology / Product

Technical values

Extrusion

Polymerization / Resin

Specific equipment