Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

Ultracur3D FL flexible resins developed by BASF are reactive urethane photopolymers designed to run on DLP/LCD, MSLA resin-type 3D printers.

The FL series represents the manufacturer's range of flexible resins, suitable for applications requiring flexibility, cushioning and durability.

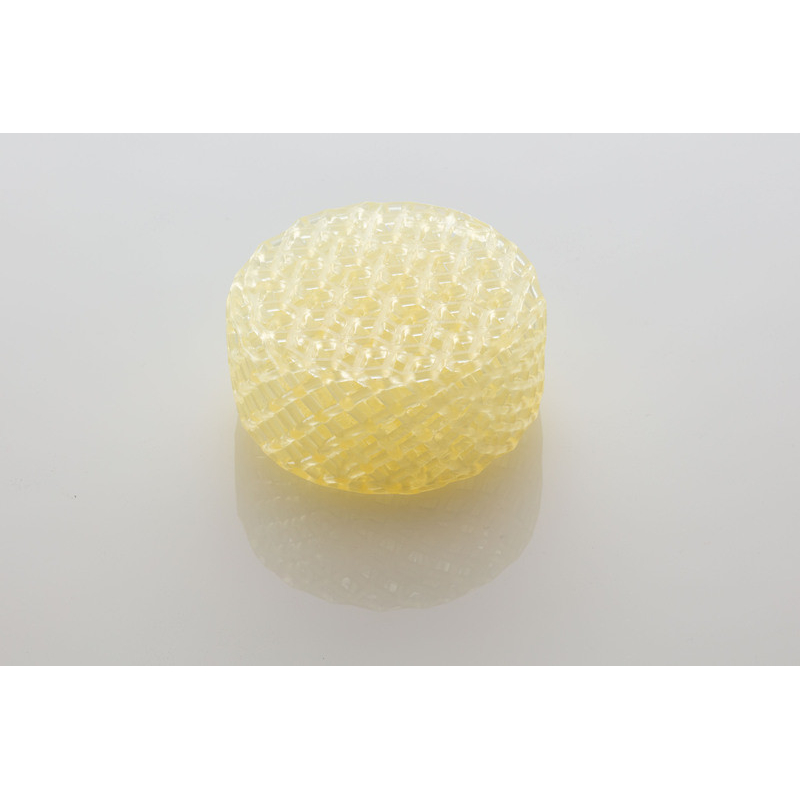

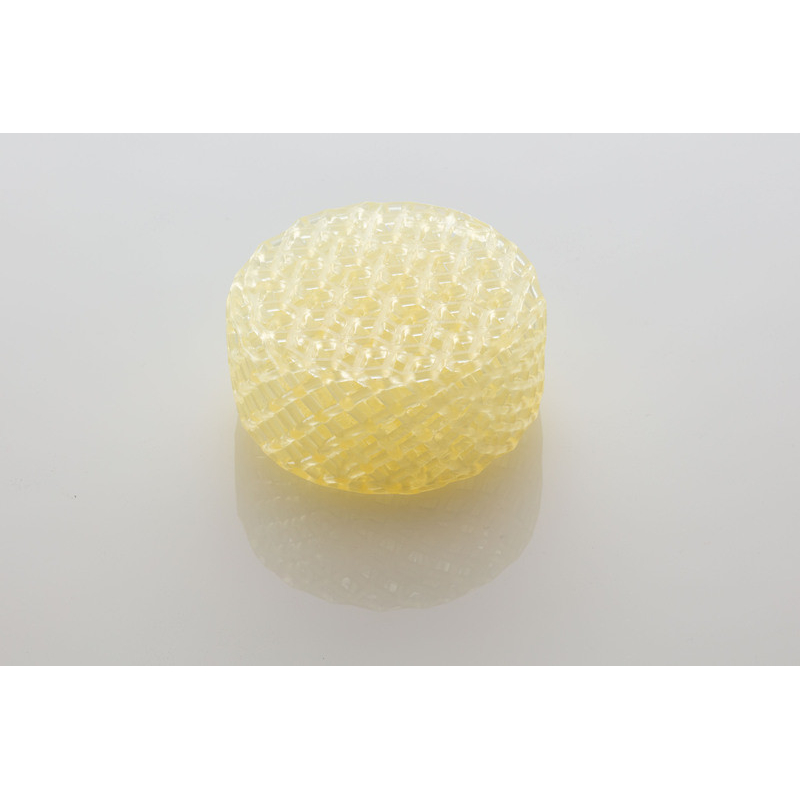

Ultracur3D FL300 from Forward AM is a resin that combines flexibility, low hardness and elasticity. It offers very low hardness (Shore 40A) and high elongation while retaining good wear resistance.

Shore 40A hardness: Ultracur3D FL300 resin is flexible and elastic. Its 40A shore hardness and high elongation rate give it excellent functional properties. Particularly suitable for cushioning and grip applications, it is also resistant over time.

High elasticity: One of the most interesting features of this FL300 resin is its high elasticity. Flexible but above all elastic and very soft, this resin has an elongation at break rate of 245%, maximising resistance to tearing, impact or stress.

Rebound: FL300 resin has good rebound properties, enabling it to absorb well while delivering a higher rebound (16%) but less good recovery after compression.

Ultracur3D FL300 resins are UV-sensitive, so they should be protected from light as soon as they are exposed. We recommend that you wear gloves when handling the resin.

Shake your bottle well before use and wait for the bubbles to disappear from your tray before printing. To find out which exposure parameters are best suited to your 3D printer for this resin, don't hesitate to consult our dedicated articles on the community.

After degreasing your part with alcohol and allowing it to dry for a few moments, don't forget to finish the post-processing by placing it in a UV chamber (for around 20 minutes, depending on its size and thickness) to obtain the expected performance and durability.

Specifications for Ultracur3D® FL 300 (40A) BASF - 1000 ml

Technology / Product

Technical values

Polymerization / Resin

Specific equipment