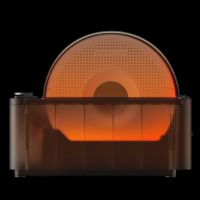

AMS 2 Pro Bambu Lab: the advanced material management system designed to optimize the 3D printing experience.

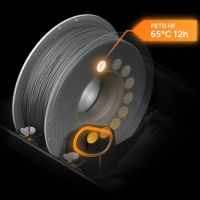

It offers features such as active filament drying at 65°C, airtight storage, support for multi-material printing up to 24 colors, and filament synchronization via RFID.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Bambu Lab AMS 2 Pro revolutionizes material management in 3D printing by integrating cutting-edge technologies to improve print quality. This automatic system offers innovative solutions for drying, storage, and feeding filaments, while facilitating the use of multiple materials and colors.

The AMS 2 Pro system is compatible with Bambu Lab H2D, H2D Laser Full Combo, X1 and P1 series. Compatibility with Bambu Lab A1 and A1 Mini will be available via an OTA update scheduled for Q3 2025.

The AMS 2 Pro features an active drying system capable of reaching a temperature of 65°C, ensuring that the filaments stay free from moisture.

This feature is crucial for preventing print defects related to moisture, such as nozzle clogs or poor-quality prints. By keeping the filaments in optimal conditions, the AMS 2 Pro ensures more reliable and higher-quality prints.

The system offers a hermetic storage compartment for the filaments, effectively protecting them from ambient humidity. This protection is crucial for preserving the properties of moisture-sensitive materials, such as nylon or PVA.

With this secure storage, users can be assured that their filaments will retain their quality and performance over the long term.

The AMS 2 Pro allows the simultaneous use of up to 24 colors or different types of materials, opening new creative possibilities. This capability is especially beneficial for projects requiring complex or multi-colored prints.

Users can easily switch between materials, simplifying the printing process and reducing preparation time.

Equipped with a brushless servo motor, the AMS 2 Pro ensures a precise and constant filament feed, thereby improving print quality.

Furthermore, the filament synchronization via RFID technology allows automatic material identification, making filament management easier and reducing the risk of errors. These innovations contribute to a smoother user experience and high-quality prints.

The AMS 2 Pro is equipped with an active ventilation opening that intelligently regulates the airflow during drying. This automatic ventilation optimizes dehumidification while maintaining the compartment's airtightness.

The result: filaments stay dry and ready for use, even after weeks of storage. This intelligent thermal management ensures consistent print quality, especially for moisture-sensitive materials, without requiring manual intervention.

Drying is even more efficient thanks to automatic spool rotation during the process. This function ensures uniform exposure to heat and dry air, allowing for homogeneous drying of the entire filament.

This rotating motion prevents moist spots and ensures optimal filament performance from the moment it's loaded. It's a subtle but essential feature for improving reliability and print consistency.

The AMS 2 Pro addresses a significant limitation of the first generation: access to filament tubes. No need to disassemble the system to remove a broken filament; now you simply open the top cover without any tools.

This direct access system greatly reduces maintenance time and allows you to quickly resume printing in case of a blockage. It’s a simple yet valuable improvement for enhanced ease of use and efficiency.

The AMS 2 Pro filament entries have been reinforced with ceramic material featuring a Vickers hardness of 1200, ensuring exceptional durability. These enhanced parts reduce wear over time, especially with abrasive filaments.

This increased strength ensures stable and reliable feeding over time, while minimizing the risk of damage to internal components. A technical choice that extends the lifespan of the device.

1. The AMS 2 Pro has an independent power port in addition to the 6-pin port. Is it really necessary?

When used alone with the H2D printer, all functions – including automatic filament feeding and drying – are available without the need for an external power adapter. However, when multiple AMS 2 Pro units are connected, particularly if some are used for multi-color printing and others for drying, the units dedicated to drying will require an external power adapter.

2. Are the X1 and P1 series printers compatible with the AMS 2 Pro?

Yes, the X1 and P1 series are compatible with the AMS 2 Pro. To enjoy only automatic filament feeding, you simply need to use the 6-pin and 4-pin cables along with a Filament Buffer or AMS Hub. No additional power adapter is required in this case. If you also want to use the drying function, an external power adapter is necessary. Full compatibility for drying on these models will be activated via an OTA update by the end of April.

3. Can an AMS and an AMS 2 Pro be used at the same time on the same printer?

Yes, it is possible to use both a first-generation AMS and an AMS 2 Pro on an H2D printer. This allows you to combine their functions depending on your multi-material printing or filament management needs.

4. Can filaments be dried during printing?

Currently, the drying function is not available on AMS 2 Pro or HT units that are actively participating in printing, including those used for automatic feeding during an ongoing job.

5. Can the printer directly power an AMS 2 Pro unit for drying?

Yes, the H2D printer is capable of powering an AMS 2 Pro unit for drying directly via its port. However, if you want to dry filament in multiple AMS 2 Pro units simultaneously, the additional units will require an external power adapter (sold separately).

6. Can the AMS 2 Pro's drying function be used without a printer?

No, the drying function requires the AMS 2 Pro to be connected to the printer via a 6-pin bus cable. The printer must be turned on and set to drying mode to activate this function. The AMS 2 Pro cannot dry autonomously without being connected to a printer.

PLA, ABS , PETG, PC, Flexible, Nylon, HIPS, ASA, PP, PC-ABS, PLA-CF, PA-CF

Specifications for Bambu Lab AMS 2 Pro

Technology / Product

Extrusion