Bambu Lab AMS HT: a solution designed to optimize 3D printing with high-performance materials.

The AMS HT ensures effective filament drying at up to 85 °C and guarantees high-quality prints by maintaining filaments in ideal conditions.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The AMS HT system from Bambu Lab revolutionizes 3D printing by offering advanced management of high-performance materials. Capable of effectively drying filaments at temperatures up to 85 °C, it ensures optimal print quality by eliminating moisture that could affect results.

The AMS HT facilitates multi-material printing: up to 4 units can be connected to the X1 and P1 series, and 8 units to the H2D series. Its compatibility with Bambu Lab printers ensures seamless integration into your workflow.

The AMS HT can reach up to 85 °C to remove moisture from technical filaments. This high temperature is ideal for materials like nylon or polycarbonate, which are often sensitive to humidity. The result: more reliable prints, without bubbles, delamination, and with better layer adhesion.

During the drying cycle, the spools rotate automatically to ensure uniform evaporation of moisture. This movement prevents cold or damp spots in the filaments, ensuring homogeneous drying, particularly useful for technical materials that are often more sensitive than standard PLA or PETG.

The AMS HT integrates automatic ventilation that controls internal humidity, ensuring a stable and airtight atmosphere. Thanks to this feature, filaments can remain stored for several weeks while maintaining optimal properties, even without constant drying. True peace of mind for long-term prints.

The AMS HT automatically recognizes official Bambu Lab filaments thanks to RFID technology. It then adjusts the drying settings according to the material without any manual intervention. A valuable time saver, and the assurance of always having drying adapted to the type of filament used.

A simple digital screen allows you to monitor the drying status in real-time. Combined with a temperature sensor and physical security, the system prevents overheating. The user maintains control at all times while benefiting from a perfectly safe drying environment.

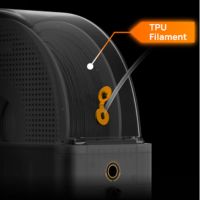

For flexible or brittle filaments, an independent filament output reduces the risk of breakage or blockage. This makes the AMS HT particularly suited for complex materials, ensuring smooth and reliable feed during multi-material or long-duration prints.

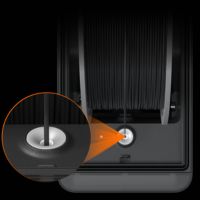

The ceramic filament inlets have a Vickers hardness of 1200, providing excellent wear resistance. This durability is essential for abrasive or technical filaments, ensuring reliable long-term operation, even under heavy use or with demanding materials.

PLA, ABS , PETG, PC, Flexible, Nylon, Composites, HIPS, ASA, PP, PC-ABS, PLA-CF, PET-CF, PA-CF

Specifications for Bambu Lab AMS HT

Technology / Product

Extrusion

Spare part