- Pre-order

The Creality K1C 2025 + CFS-C is the evolution of the K1C model, now in Combo version, designed to deliver precision, speed, and reliability. Compatible with a wide range of filaments, including carbon composites, it features a Clog-Free extruder with Quick-swap nozzles and a sturdy frame.

This CFS-C version allows multicolor printing (up to 4 filaments). Perfect for rapid prototypes, small series, and complex creations, it ensures consistent, high-quality results for every project.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Creality K1C 2025 + CFS-C is the evolution of the K1C model, designed for smoother, faster, and more reliable 3D printing. Thanks to the CFS-C multi-color module, it allows easy printing with multiple filaments and colors in a single print, without compromising precision or speed.

It combines compatibility with technical filaments and carbon composites, an intuitive interface, optimized responsiveness, and advanced features. Every print maintains consistent quality, while project management becomes simple and efficient, offering a complete and versatile 3D experience.

The CFS-C module enables multi-color printing with up to 4 filaments on the K1 series. It ensures smooth filament transitions, allowing visually complex prototypes and decorative parts.

This feature opens up new creative possibilities while maintaining precision and quality across all prints for professional and consistent results.

The Creality CFS-C removes filament waste externally through its cutting mechanism and integrated buffer. This design prevents residue from accumulating inside the printer, reducing the risk of clogs or print quality issues.

A simple yet effective system that simplifies maintenance and ensures a smoother workflow.

.jpg)

The CFS-C continuously monitors each spool: filament run-out, tangles, or cutter wear are detected automatically.

If an issue occurs, printing pauses, minimizing material waste and ensuring reliable multi-color prints with consistent quality.

The Creality K1C 2025 + CFS-C features a modernized UI display for easy access to essential functions. Navigation is simplified, G-code file search optimized, and audio alerts indicate power-on, start, and end of printing.

Everything is designed to make the user experience smoother and more controlled, even for complex prints.

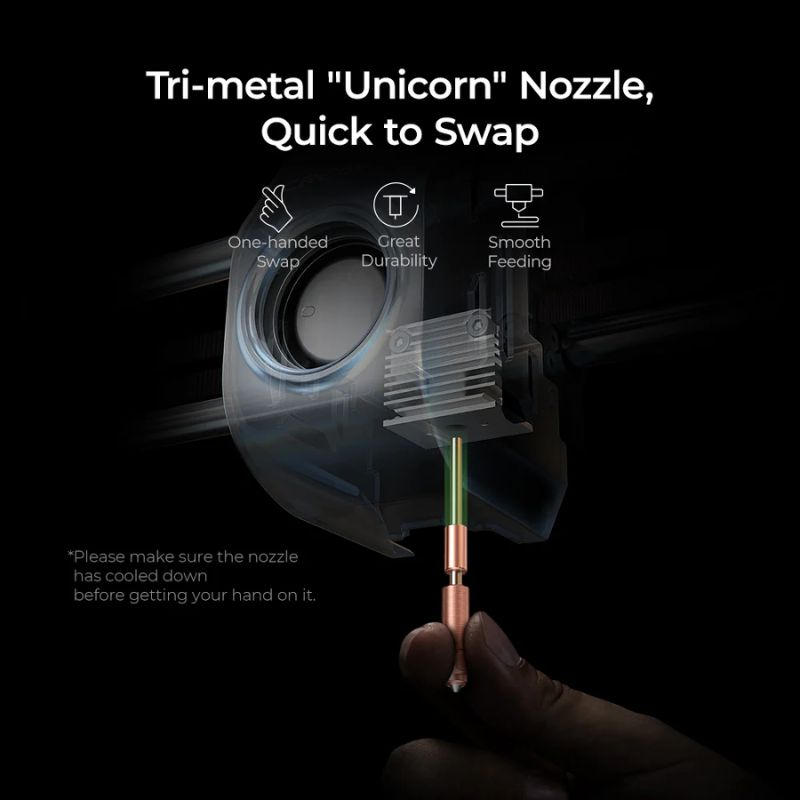

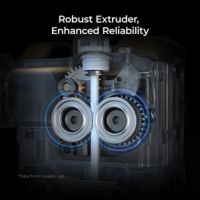

The Clog-Free extruder ensures continuous filament feeding, even with composite materials. It reduces interruptions, limits defects, and guarantees uniform quality across all prints.

This reliability is essential for professional users and demanding makers, allowing them to focus on creativity and project complexity rather than mechanical adjustments.

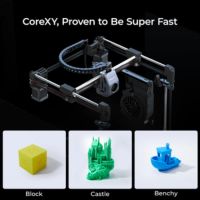

The Creality K1C 2025 + CFS-C combines optimized motors and robust mechanics to achieve high print speeds (up to 600 mm/s) while maintaining maximum precision.

Prototypes and small series can be produced quickly without sacrificing quality. This performance is ideal for production workshops, design studios, or makers aiming to reduce time from concept to final result.

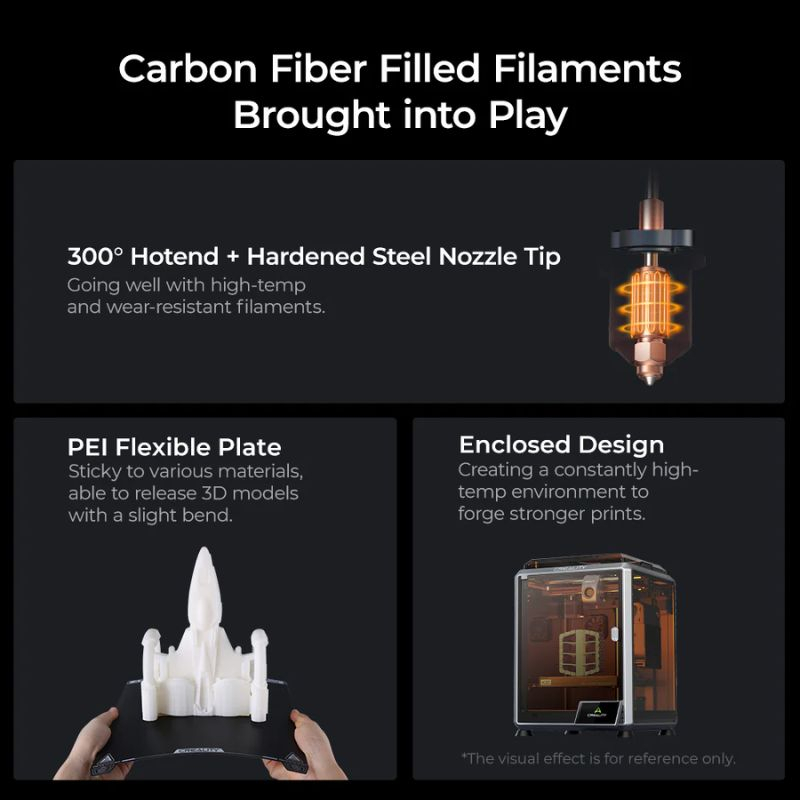

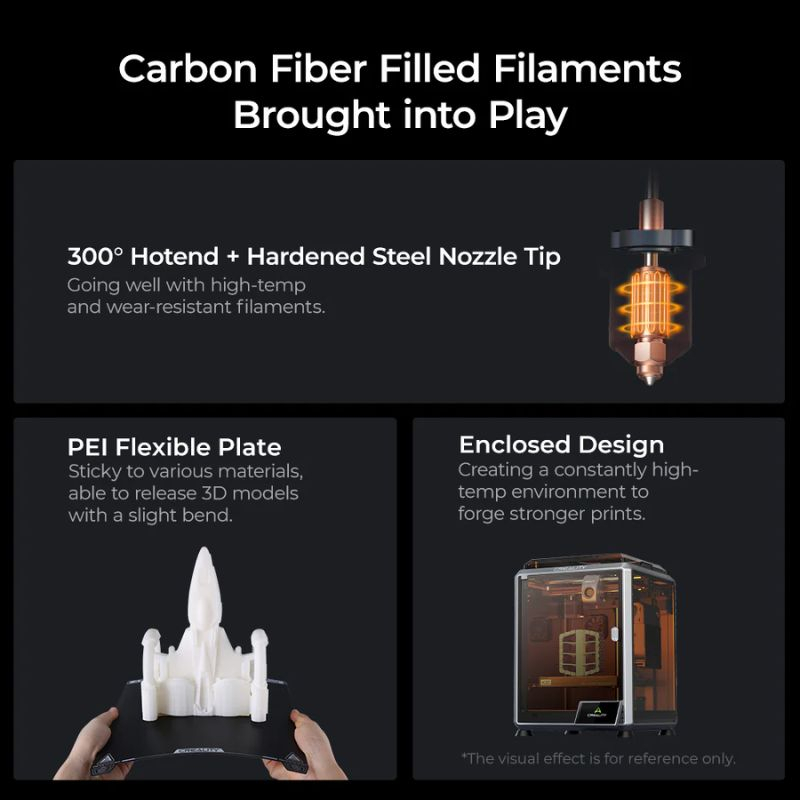

The Creality K1C 2025 + CFS-C supports a wide range of filaments, from standard PLA to reinforced carbon composites. This flexibility allows prints to be tailored to any project, whether functional prototypes, technical parts, or complex artistic models.

Users can fully exploit the characteristics of each filament while achieving reliable, precise prints every time.

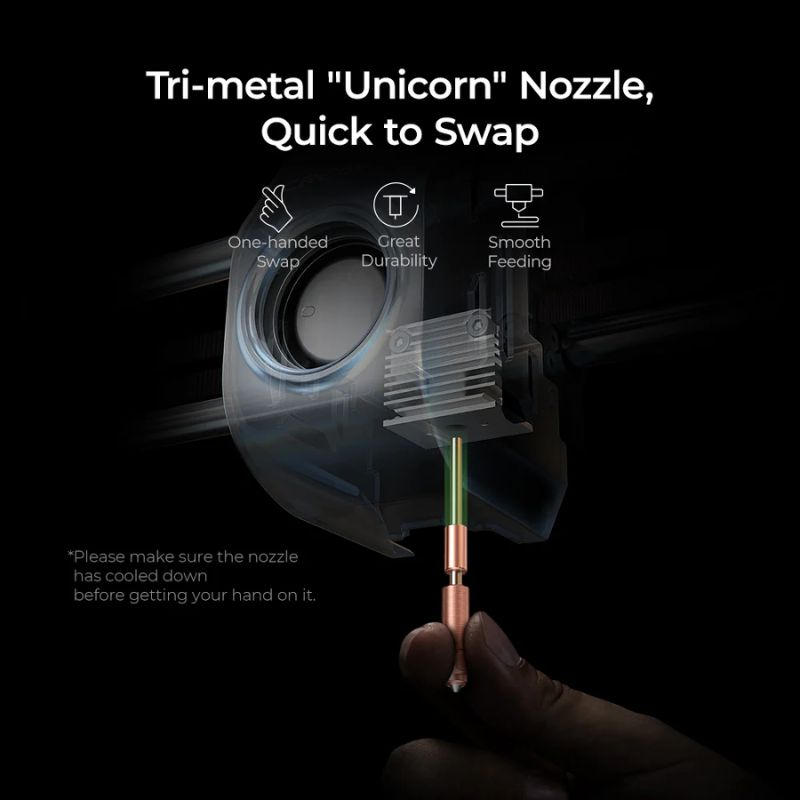

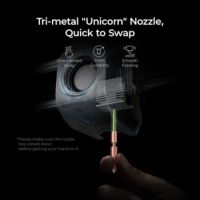

Quick-change nozzles allow diameter or material swaps in seconds. This significantly reduces downtime and minimizes handling errors, making multi-material and multi-color printing easier.

This feature is particularly useful for makers and professionals who want to switch filaments without interrupting production flow.

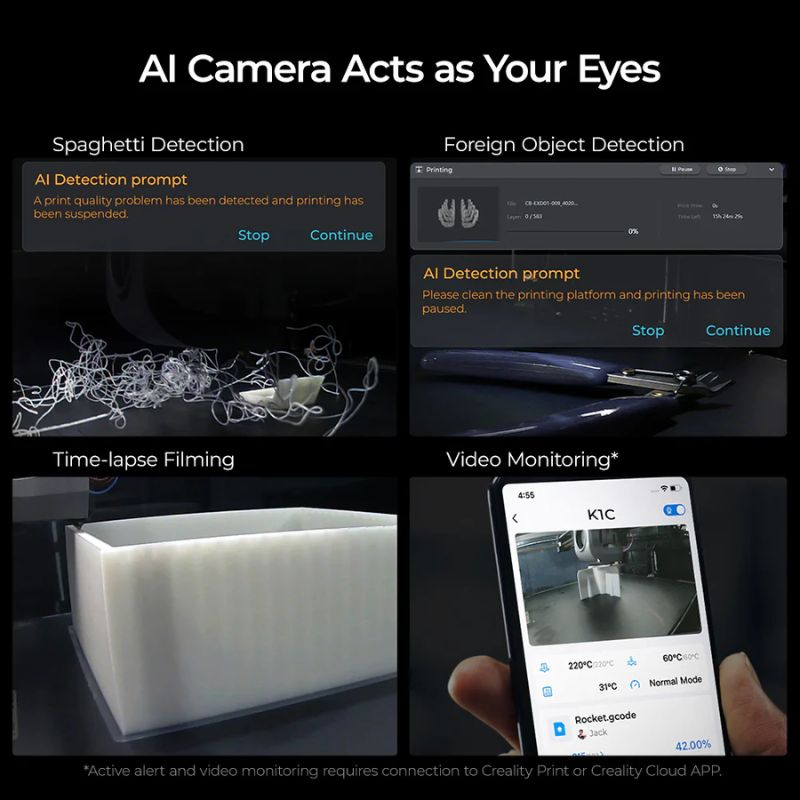

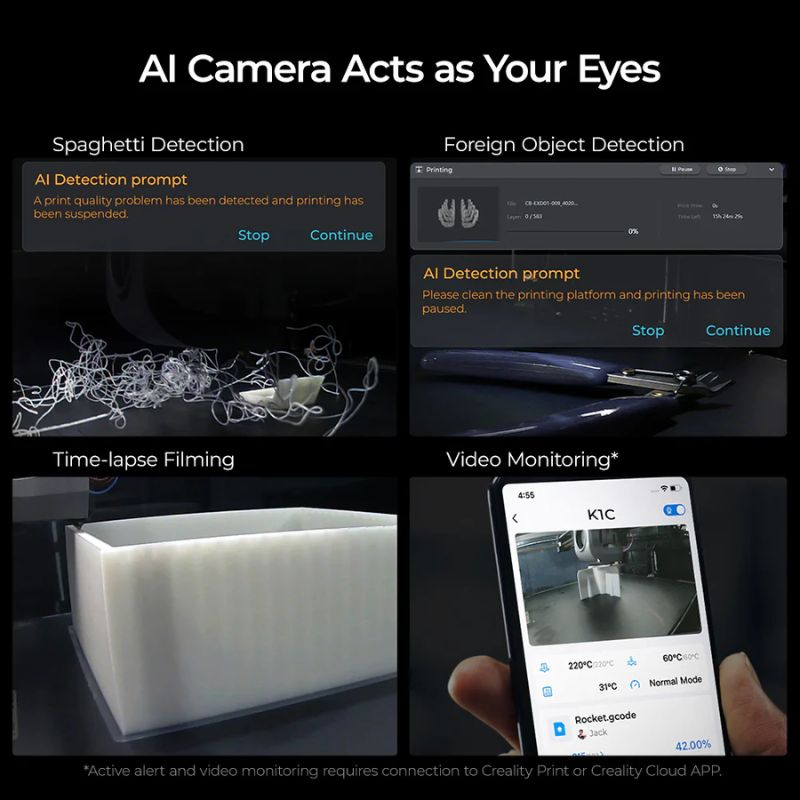

The integrated AI camera monitors the print and automatically detects anomalies, providing precise remote control.

It enhances safety and allows quick intervention if needed, ensuring consistent quality and peace of mind for long or complex prints, especially useful for professional prototypes and small series.

The advanced ventilation system ensures even heat dissipation, minimizing warping and improving surface quality. It delivers sharp prints even for complex geometries and demanding materials.

Cooling is optimized in 3 stages: hotend ventilation, part cooling, and auxiliary enclosure airflow.

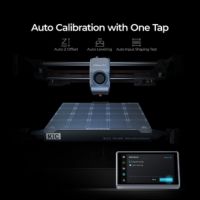

Automatic and regional bed leveling ensures a perfect first layer and consistent accuracy across the print surface.

This reduces manual intervention and errors, saving time and ensuring reliable results for every project, whether for industrial prototypes or detailed creations.

The bed and extruder maintain stable, filament-appropriate temperatures, ensuring excellent adhesion and smooth printing.

Temperature control minimizes warping and deformation, allowing the use of technical or composite materials (hotend 300°C) without compromising quality.

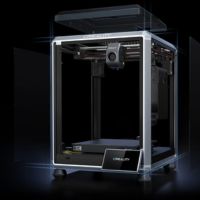

The enclosed chamber protects prints from temperature fluctuations and drafts, ensuring dimensional consistency and improved surface quality.

It also enhances safety and is essential for temperature-sensitive filaments, such as composites or PETG.

The PEI bed provides excellent adhesion from the first layer and allows easy part removal. It reduces the risk of warping or damage during removal and ensures a smooth, reliable production flow, especially for long or complex prints.

The reinforced frame minimizes vibrations and improves printing precision.

This mechanical stability guarantees consistent results over time, whether for industrial parts, detailed prototypes, or complex artistic creations.

The charcoal filter system reduces emissions, providing a safer and more comfortable work environment.

This combination of comfort and performance is ideal for home or professional users seeking an efficient and quiet printer (Silent mode <45dB).

Compatible with Creality Slicer and Creality Cloud, the Creality K1C 2025 + CFS-C enables precise model preparation, remote monitoring, and optimized support generation.

The interface simplifies multi-color printing and parameter adjustments for each filament, delivering consistent, professional results, even for complex or long-duration projects.

The K1C 2025 + CFS-C combines technical innovations, reliability, and responsiveness. Its clog-free extruder, optimized frame, and CFS-C multi-color module allow easy management of multiple filaments and colors in a single print, offering consistent precision and unlimited creativity.

It is ideal for rapid prototypes, small series, and complex creations. With the CFS-C, high-quality multi-color prints can be produced without compromising speed or accuracy, making this printer a reliable, high-performance, and versatile solution for makers and demanding professionals.

220 x 220 x 250 mm

100 microns

600 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Composites, ASA, PP, PLA-CF, PET-CF, PA-CF

Specifications for Creality K1C 2025 + CFS-C

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites