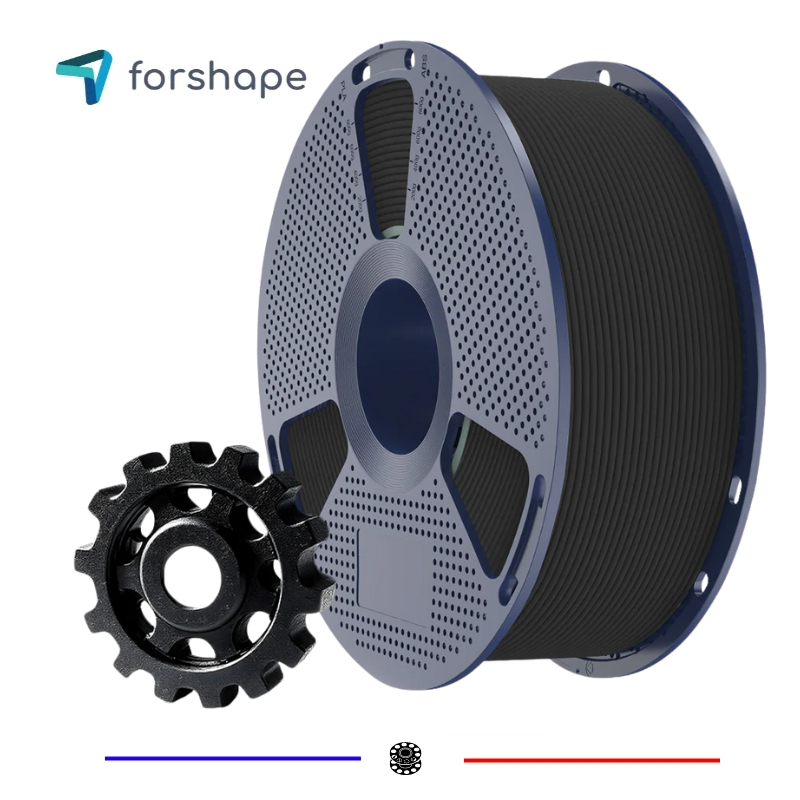

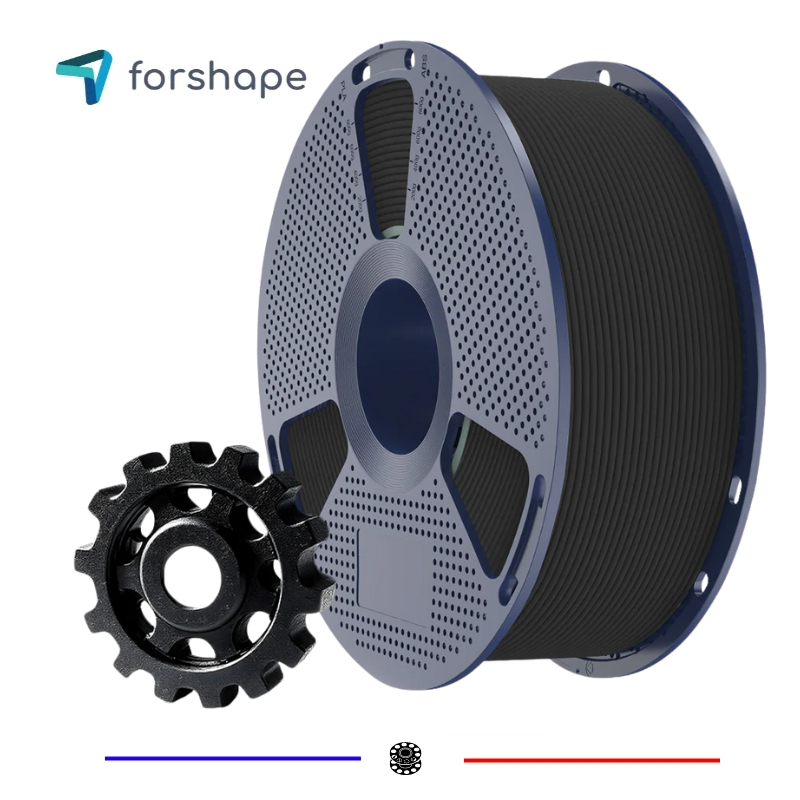

The ecoPETG-CF Forshape filament is a modified PETG with a carbon fiber filling, designed to meet the needs of users looking for strength and reliability. This material combines the ease of printing of PETG with significantly increased rigidity due to the addition of carbon.

The resulting parts have excellent dimensional stability, a significant reduction in warping, and an elegant matte finish. This filament is particularly suitable for the production of technical and functional parts, exposed to mechanical stress.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The ecoPETG-CF Forshape is a 3D filament resulting from the combination of a PETG and a rate of carbon fibers. Thanks to this formulation, it is possible to obtain a material with a mechanical resistance significantly higher than that of a standard PETG, while maintaining a great ease of printing. Users appreciate the low tendency to warp, good inter-layer adhesion and a homogeneous, slightly textured finish that enhances each print.

The use of carbon fibers gives the filament a increased rigidity and a weight reduction compared to a standard PETG. This feature makes it a perfect filament for the production of functional prototypes, structural parts, or components subjected to repeated mechanical stresses. Its matte finish, obtained naturally thanks to the presence of carbon, also improves the visual aspect of prints, limiting the shine often associated with classic PETG.

Carbon reinforced rigidity : The addition of carbon fibers significantly increases the rigidity and resistance of the PETG. The pieces obtained deform much less under stress, making it a material particularly suited to structural elements, technical supports, and prototypes requiring reliable mechanical performance. Compared to standard PETG, the flexural strength is significantly higher, while maintaining stable and regular printing.

Low thermal deformation : One of the limitations of PETG is its sensitivity to residual heat and shrinkage phenomena. With the ecoPETG-CF Forshape version, the presence of fibers limits deformation and improves dimensional stability. Parts remain true to the planned dimensions, even during long prints or complex geometries. This feature is particularly valuable for professional users who demand constant precision in their manufacturing.

Elegant matte finish : The visual aspect of prints directly benefits from the carbon load: surfaces appear matte, homogeneous, and less sensitive to reflections. This effect masks the printing layers, making the parts more aesthetic, even without post-processing. This natural finish also allows to obtain prototypes or final parts with a more professional rendering, without the shiny plastic effect typical of standard filaments.

To fully benefit from the ecoPETG-CF Forshape, a hardened steel or ruby nozzle is strongly recommended, as carbon fiber has a marked abrasive effect on brass nozzles. An extrusion temperature between 240°C and 260°C is advised, associated with a heated bed set between 70°C and 80°C. Using a closed enclosure is not essential but improves the regularity of the prints. Finally, a moderate printing speed (40–60 mm/s) guarantees a good compromise between surface quality and productivity.

Important: Printing this filament with a 0.4mm nozzle is possible but requires a higher extrusion temperature. We strongly recommend using a 0.6mm nozzle to print this carbon fiber-filled filament without issues.

Specifications for ecoPETG-CF Forshape - 1.75mm - 1 kg

Technology / Product

Extrusion

Specific equipment

Installation / Prerequisites