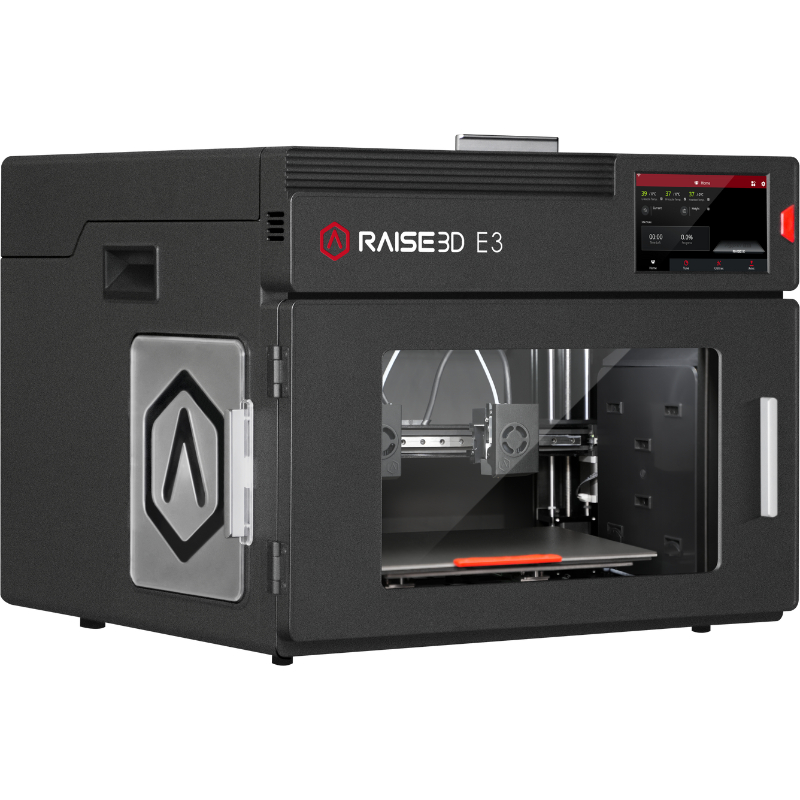

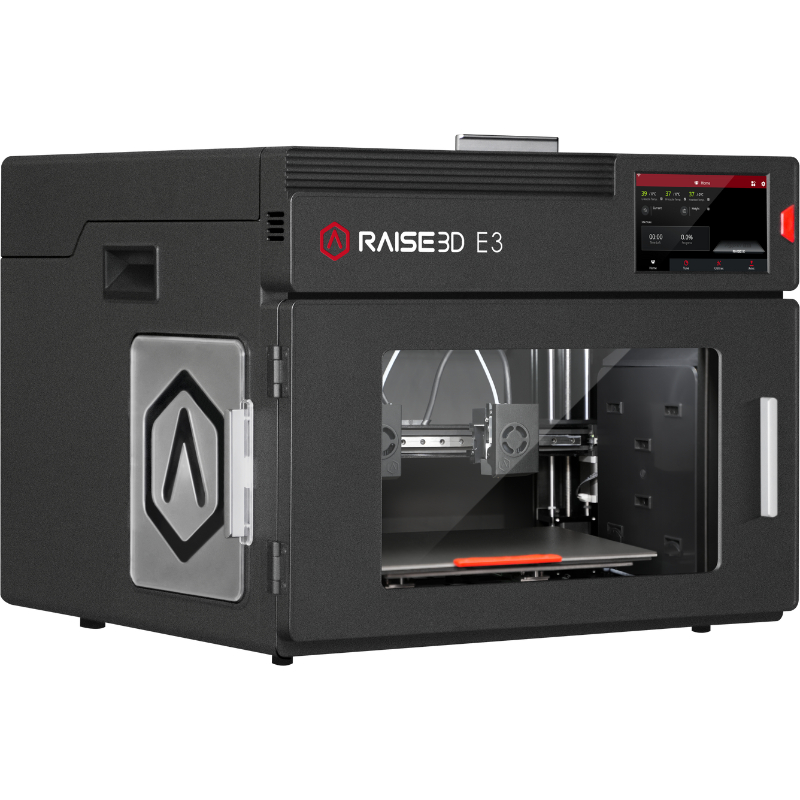

The Raise3D E3 is a professional 3D printer designed to deliver reliability, precision, and versatility. It is aimed at businesses looking to produce prototypes, technical parts, or small series consistently.

Thanks to its robust chassis, optimized printing volume, and compatibility with a wide range of materials, it meets the varied needs of industry and design. Paired with the IdeaMaker software, it offers a smooth and efficient experience, even for demanding projects. An ideal solution for combining productivity and quality.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Raise3D E3 is a professional 3D printer designed to provide a high level of reliability, of accuracy and of flexibility in additive manufacturing. It is particularly distinguished by its two possible configurations: CF Kit and Flex Kit, which significantly expand its uses.

This modularity allows professionals to choose the configuration that best suits their needs: Technical parts reinforced with fibers or printing of flexible materials demanding. The Raise3D E3 thus establishes itself as an accessible and efficient machine for prototyping, production and advanced experimentation.

The Raise3D E3 stands out for its modularity, with two interchangeable printing kits machine the ability to meet different needs. The CF Kit allows for the printing of fiber-reinforced composite filaments, while the Flex Kit is designed for flexible and elastomeric materials. This dual approach gives the Raise3D E3 a unique versatility in its category.

The Flex Kit from the Raise3D E3 was designed for printing. flexible polymers and elastomers You didn't provide any text to translate. Please provide the text you want to be translated from French to English.TPU, TPE, etc.). Its design reduces the risk of jamming and improves flow stability, ensuring successful prints even with complex filaments to extrude.

.png)

The CF Kit Raise3D E3 is specially designed for printing. composite materials loaded with carbon or glass fibers. This configuration strengthens the parts, gives them increased rigidity, and allows the production of prototypes or functional elements with high mechanical performance.

.png)

The printing volume of the Raise3D E3 meets the common needs of design offices and manufacturing workshops. It allows to carry out prototypes, of the functional parts and some small series with constant accuracy.

.png)

Thanks to an optimized extruder and robust mechanical components, the Raise3D E3 ensures a great finesse of details and a regular surface quality, even on complex geometries.

.png)

Whether it's about PLA, , ABS, , PETG or more technical polymers, the Raise3D E3 adapts to a wide variety of materials. With its interchangeable kits, it covers a broad spectrum of applications ranging from flexible prototyping to reinforced parts.

.png)

The rigid and closed structure of the Raise3D E3 limits the vibrations and stabilizes the thermal environment. This design ensures a constant and reliable impression, even during intensive use in the workshop.

.png)

Compatible with the auxiliary charger Raise3D, E3 improves the feeding of flexible filaments like the TPU. This technology allows to reach up to 200 mm/s while ensuring stable extrusion, ideal for the production of high-quality flexible parts.

.png)

The Raise3D E3 supports the reinforced composite filaments and benefits from Pro Ironing technology. Combined with ideaMaker profiles, it allows for ultra-smooth finishes with an average roughness less than 2 µm, close to injection molding.

.png)

Thanks to his independent dual extruder (IDEX), the Raise3D E3 supports mirror, duplication, two-color, and two-material modes. This technology allows for doubling productivity and exploring new multi-material applications.

.png)

The Raise3D E3 has two integrated compartments with desiccant, keeping the filaments dry. This system reduces problems related to humidity, improves dimensional accuracy and ensures better print consistency.

.png)

Equipped with a 9-point leveling sensor, the Raise3D E3 automatically adjusts the nozzle-bed distance. Calibration optimizes adhesion. and improves the overall quality, even on slightly irregular surfaces.

.png)

Equipped with an end-of-filament sensor and a resumption after power outage, the Raise3D E3 secures long printouts. It prevents material loss and resumes exactly where the process was interrupted.

The printer is controlled via IdeaMaker, a slicer developed by Raise3D. Its simple interface masks advanced functions: optimized profiles for different materials, multi-printer management and advanced customization of settings. IdeaMaker makes the transition from the 3D model to the print file while ensuring optimization of results.

The Raise3D E3 combines reliability and modularity with its two dedicated kits. It is ideal for professionals looking for a single machine capable of covering multiple types of applications. highly technical rigid parts or fast and accurate flexible impressions. Its software ecosystem, print quality, and robustness make it a relevant solution for design offices, prototyping workshops, and small industrial productions. A machine that deserves its place as a reliable and versatile production tool.

330 x 240 x 240 mm

25 microns

200 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Filament Support, Composites, PVA, HIPS, ASA, PP

Specifications for Raise3D E3

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites