3D printing, also known as additive manufacturing, is an innovative technology that turns a digital model into a physical object, layer by layer.

To learn more about the different machines, check out our range of 3D printers.

This revolutionary method is gaining traction across many sectors, from industrial prototyping to customized object creation.

What is 3D printing?

3D printing involves creating three-dimensional objects by successively stacking layers of material, typically plastic, but also metal, resin, or other substances. This technology relies on a digital model designed using computer-aided design (CAD) software.

Unlike traditional machining processes that remove material, 3D printing adds material, layer by layer, to bring a digital model to life.

Today, this technology is becoming increasingly accessible, finding its way into both hobbyist workshops and industrial production lines.

How does a 3D printer work?

The 3D printing process consists of several key steps:

- Designing the 3D model: It all starts with creating a digital 3D model using modeling software such as Blender, Fusion 360, or Tinkercad. You can also download ready-to-print models from platforms like Thingiverse.

- Slicing the model: The 3D file is then sliced into thin layers using a software called a “slicer.” This software generates a code (G-code) that will guide the printer.

- Layer-by-layer printing: The printer successively deposits layers of material – plastic, resin, powder, depending on the technology – until the final object is formed.

The main 3D printing technologies

There are several 3D printing methods, each suited to specific needs:

| Technology | Principle | Common Materials | Applications |

|---|---|---|---|

| FDM (Fused Deposition Modeling) | Melting and extruding thermoplastic filament | PLA, ABS, PETG | Prototyping, home use |

| SLA (Stereolithography) | Curing liquid resin with a laser | Photopolymer resins | High precision, jewelry, dental |

| SLS (Selective Laser Sintering) | Laser sintering of powdered material | Nylon, TPU | Technical parts, small series |

| DLP (Digital Light Processing) | Photopolymerization with a light projector | Liquid resins | Jewelry, dental prosthetics, miniatures |

| MJF (Multi Jet Fusion) | Binder jetting and thermal fusion | PA 12, PA 11 | Functional parts, serial prototyping |

| LCD (Masked Stereolithography / MSLA) | UV light curing through a masked LCD screen | UV resins | Miniatures, prototyping, home use |

| DMLS (Direct Metal Laser Sintering) | Direct laser melting of metal powder | Aluminum, titanium, stainless steel | Aerospace, tooling, implants |

| WAAM (Wire Arc Additive Manufacturing) | Metal wire deposition via electric arc (similar to MIG welding) | Steel, titanium, aluminum | Large metal parts, heavy industry |

Why is 3D printing so appealing? Its strengths… and countless applications

3D printing is attracting a growing number of users, both professionals and hobbyists, because it is revolutionizing design and production methods. Here’s why this technology continues to gain traction:

Extreme customization

Each part can be tailor-made – dimensions, shape, function… It’s the perfect tool for unique projects or small production runs.

Lower costs and faster turnaround

Need to create a prototype or final part in just a few hours, with no tooling or intermediaries? 3D printing makes it possible – and at a lower cost.

Unlimited complexity

Organic shapes, internal lattice or hollow structures – once impossible to manufacture – are now easy to produce.

Local and sustainable production

Producing on demand, locally, reduces inventory, waste, and transportation. 3D printing supports a more responsible and sustainable approach.

Main application fields of 3D printing

| Sector | Examples of Use |

|---|---|

| Medicine | Custom prosthetics, dental implants, surgical tools, tissue printing (bioprinting) |

| Aerospace & Automotive | Lightweight parts, performance improvement, rapid prototyping or spare parts manufacturing |

| Architecture & Design | Models, furniture, lighting, custom decoration |

| Education | Educational models, research projects, science communication |

| Industry | Tooling, functional parts, on-demand production |

| Hobbies & DIY | Custom figurines, cosplay accessories, gadgets, everyday objects |

3D Printing: A catalyst for industrial innovation

For businesses, additive manufacturing represents a strategic breakthrough. It reduces development time, optimizes costs, and enables the production of technical parts that would be impossible to manufacture using traditional methods.

Market leaders such as Ultimaker, Raise3D, HP or Formlabs offer reliable, precise, and robust printers, suitable for intensive professional use.

However, the professional segment is also welcoming new, dynamic players:

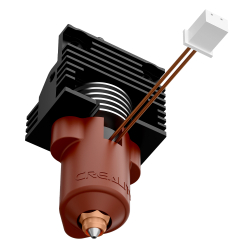

- Creality, known for its affordable FDM machines, is now developing professional-grade models with large build volumes and high precision.

- Bambu Lab is gaining traction with ultra-fast, multi-material printers featuring advanced automation.

- Elegoo, initially focused on the consumer market, is moving upmarket with high-performance LCD resin printers tailored to professional needs.

What’s next for this technology?

The additive manufacturing market is experiencing exponential growth. Upcoming innovations include:

Bioprinting of living tissues

3D printing of entire concrete buildings

Customized food printing

4D printing, where objects change shape over time

Frequently Asked Questions (FAQ)

Which 3D printer should I choose?

For beginners, an FDM printer like the Creality Ender 3 is ideal. For finer details, opt for an SLA printer.

Can you print any kind of object?

Almost anything – as long as the size and material are compatible.

Is 3D printing eco-friendly?

It generates less waste compared to traditional manufacturing, especially when using biodegradable materials.

Conclusion

3D printing is far more than a passing technological trend. It is a true revolution that is transforming the way we design, produce, and personalize objects.

Whether you’re a curious hobbyist or an innovation-driven professional, this technology has the potential to meet your needs with both efficiency and creativity.

✅ Why Choose Polyfab3D?

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

Contact us now for a personalized recommendation tailored to your needs, budget, and ambitions.