Metalworking is undergoing significant changes. Traditional welding and cutting techniques are gradually being replaced by more precise, automated solutions.

Among these, laser welding and CNC cutting offer faster, simpler, and highly accurate alternatives. For modern workshops, the xTool MetalFab perfectly demonstrates this blend of performance and versatility.

Understanding Laser Welding and Its Applications

The principle of laser welding is based on a concentrated beam that locally heats the metal until it melts. This approach provides several technical advantages:

- Exceptional precision: the laser targets very small areas, minimizing deformation.

- High production speed: instantaneous melting accelerates the assembly process.

- Material versatility: stainless steel, aluminum, and copper can all be welded effectively.

- Non-contact assembly: the metal is not subjected to mechanical stress, reducing the risk of contamination.

The applications are wide-ranging. The automotive industry uses laser welding to assemble thin components with tight tolerances. In electronics, sensitive parts can be welded without risk of damage.

The aerospace sector benefits from the precision for structural parts, while custom workshops can produce prototypes and small series with high accuracy.

CNC Metal Cutting: Precision and Repeatability

CNC cutting allows metal to be shaped according to digital files. This method gradually replaces manual cutting, offering:

- Complex shapes made easy: rounded edges, interior cuts, and intricate patterns can be executed effortlessly.

- Perfect repeatability: each part is identical, essential for series production.

- Reduced waste: precision minimizes material loss.

- Enhanced safety: operators are less exposed to sharp tools and flying metal debris.

Industries benefiting from CNC cutting include metal furniture, industrial components, decorative elements, and even custom jewelry.

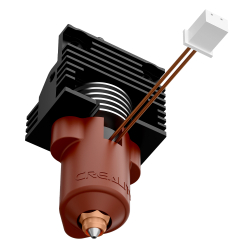

xTool MetalFab: A Versatile Tool

The xTool MetalFab combines laser welding and CNC cutting in a single machine. This all-in-one solution streamlines operations in modern workshops:

- Versatility: capable of performing both precise welds and complex cuts.

- Intuitive interface: easy-to-use software reduces the risk of errors.

- Multi-metal compatibility: ideal for working with steel, aluminum, or copper.

- Built-in safety: laser protection and anti-collision features for CNC operations.

This combination allows professionals to produce small series, prototypes, or customized projects with consistent quality.

Practical Applications of the MetalFab

The range of applications for this type of tool is extensive. Metal artwork, decorative items, repairs and construction in automotive, aerospace, and robotics, metal cleaning, prototypes…

Rapid Prototyping

The solution from xTool enables quick creation of metallic prototypes that can be tested and adjusted before final production.

Engineers can experiment with different configurations without needing multiple machines.

Custom Parts

Artisans and designers benefit from the machine to produce unique parts or small custom series. CNC cutting shapes the components, while laser welding assembles them with precision.

Targeted Repairs

Laser welding allows damaged parts to be repaired without unnecessarily heating the entire piece, which is difficult with traditional methods.

Training and Education

Technical schools and engineering offices can use these tools to introduce students to modern metal fabrication processes.

Comparison with Traditional Methods

| Criterion | Traditional Welding | Manual Cutting | xTool MetalFab |

|---|---|---|---|

| Precision | Medium | Limited | Very High |

| Speed | Moderate | Slow | Fast |

| Shape Flexibility | Low | Medium | Very High |

| Safety | Variable | Manual Risk | Integrated |

| Repeatability | Variable | Low | Exact |

Tips to Get the Most Out of This Solution

- Prepare files carefully: each cut or weld depends on the precision of the CAD or vector file.

- Choose the right metal: stainless steel, aluminum, or copper depending on the application.

- Adjust settings: tailor power, speed, and depth for each material.

- Regular maintenance: cleaning laser lenses and checking CNC axes ensures consistent performance.

Trends and Outlook

Metal fabrication is moving toward automation and precision. All-in-one machines reflect this trend, offering versatility and reliability.

In the future, integrating artificial intelligence could automatically adjust welding and cutting parameters, making workshops even more productive and safer.

Conclusion

Laser welding and CNC cutting are no longer limited to large industries. With the xTool MetalFab, it is possible to produce complex and precise metal parts in small to medium-sized workshops.

This machine opens up opportunities for prototyping, custom manufacturing, repairs, and training, while ensuring consistent quality and high safety standards.

✅ Why Choose Polyfab3D?

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

Contact us now for a personalized recommendation tailored to your needs, budget, and ambitions.