Glass is a common material in laser engraving for creating decorative items, glassware, bottles, or trophies. When you want to personalize or industrialize a marking, laser engraving on glass offers a rare combination: sharp lines, permanent markings, and aesthetic possibilities.

However, achieving this requires precise knowledge of the material, the method, and the machine settings.

Types of Laser Engraving on Glass

There are fundamentally three processes, each with different objectives:

Surface Glass Engraving

The beam targets the outer layer of the glass to alter its surface structure. The desired effect is often a frosted, white, or satin appearance that contrasts with the transparency of the material. This is the most common method for logos, text, and simple designs on glasses, bottles, or carafes.

- Advantages: Easy implementation, good readability, compatible with curved surfaces.

- Limitations: Risk of microcracks if energy is poorly calibrated; sometimes loss of sharpness if the tool is inappropriate for the glass type.

Internal (Sub-Surface) Glass Engraving

The laser is focused inside the transparent volume, creating small pinpoint micro-fractures that, when combined, form a 3D image “trapped” within the mass. This technique produces the effect of a floating design inside a crystal cube or glass block.

- Advantages: Premium finish, intact surface, spectacular visual effect.

- Constraints: Requires suitable optics and source, as well as glass without inclusions or internal stress.

Glass Embossing

Glass embossing involves creating a permanent relief on the surface of the glass by using the laser to locally heat the material and slightly deform it. This technique shapes the surface to achieve a tactile and visual embossed effect.

- Advantages: Aesthetic and tactile effect, excellent durability, compatible with high-end product customization.

- Limitations: Requires precise control of laser power and speed to avoid cracks or unwanted deformations; less suitable for very thin glass.

Which Laser Engraving Technology to Use on Glass? Focus on UV Laser

Not all lasers produce the same result on glass. Short-wavelength (UV) lasers have introduced a more precise approach.

- – Very high focal point precision (fine lines, millimetric details).

- – Less thermal diffusion: cold engraving possible to reduce cracks and soot deposits.

- – Capability to work sub-surface to create pinpoint marks without damaging the surface.

CO₂ lasers, such as the one in the xTool P3, can also engrave glass, but only on the surface. This technology heats the material to produce a frosted or satin marking, which works well for text or simple patterns on bottles, glasses, or plates.

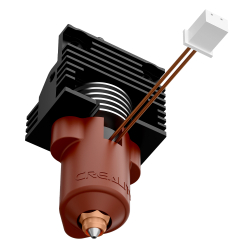

Example of a UV Glass Engraving Machine

The xTool F2 Ultra UV is a 5 W ultraviolet laser engraver designed for artisans, studios, SMEs, or creators seeking maximum precision, premium quality, and versatility.

It operates cold and is particularly suitable for glass, crystal, acrylic, ceramics, plastic, or other fragile or transparent materials.

Glass Preparation and Best Practices Before Laser Engraving

- Thorough cleaning: dust, fingerprints, and oils reduce quality and may cause defects.

- Thickness and uniformity check: prefer an identical test sample.

- Positioning and securing: immobilize the object without local mechanical stress.

- If necessary: apply a temporary absorbing film to facilitate marking.

Essential Workshop Settings

Power and Speed

Too much power at low speed causes cracks. It is better to use multiple low-energy passes than a single intense pass.

Focus and Defocusing

For surface engraving, slight defocusing reduces energy density and produces a softer mark. For sub-surface engraving, the focus must be precise to target the desired internal volume.

Repetition and Spacing

In sub-surface engraving, the placement of points determines visual density and sharpness. Incorrect spacing may affect the result or cause cracks.

Use of Liquids for Internal Glass Engraving

When performing internal laser engraving on glass, the curvature of the piece can cause optical distortions that complicate precise focusing. To address this, immersion liquids are used to minimize these effects and ensure a constant, accurate focal point. This significantly improves sharpness and precision of the internal design.

Common Mistakes and How to Correct Them

- Microcracks: reduce power, increase speed, divide work into passes.

- Too light marking: check focus, adjust density, or use an absorbing pre-treatment depending on the laser.

- Visible contamination: redo cleaning; consider a final rinse to remove residues and dust.

- Distorted patterns on curved pieces: use appropriate software correction.

Concrete Application Examples

- Customized glassware: flutes, glasses, carafes for gifts or events.

- Trophies and recognition items: internally engraved crystal blocks for a premium look.

- Decorative objects: cubes and plates with 3D patterns, portraits “trapped” inside the mass.

- Prototyping and small series: for workshops, creators, or studios producing limited runs.

Post-Engraving Care and Finishing

Depending on the desired aesthetic, surface engraving can benefit from light polishing; for internal engravings, simple cleaning is sufficient for a clean result.

For premium products, consider scratch-resistant packaging and recommend hand washing.

Conclusion

Laser engraving on glass combines technique, precision, and craftsmanship. When mastered, this technique produces aesthetic, durable, and personalized objects. However, it requires rigor, testing, and patience. Test, document, adjust: that is the key to success.

✅ Why Choose Polyfab3D?

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

Contact us now for a personalized recommendation tailored to your needs, budget, and ambitions.