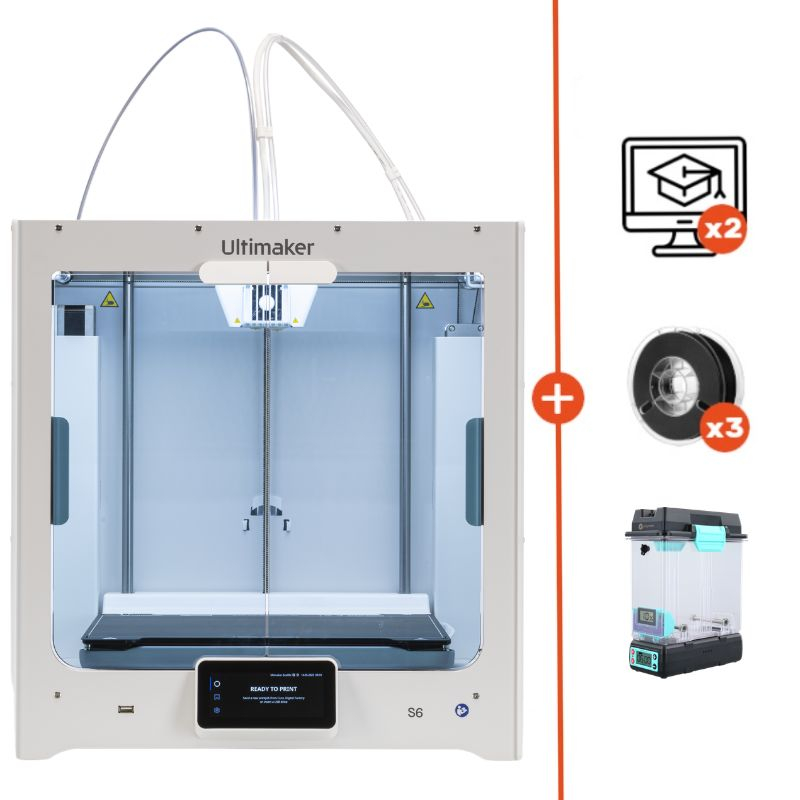

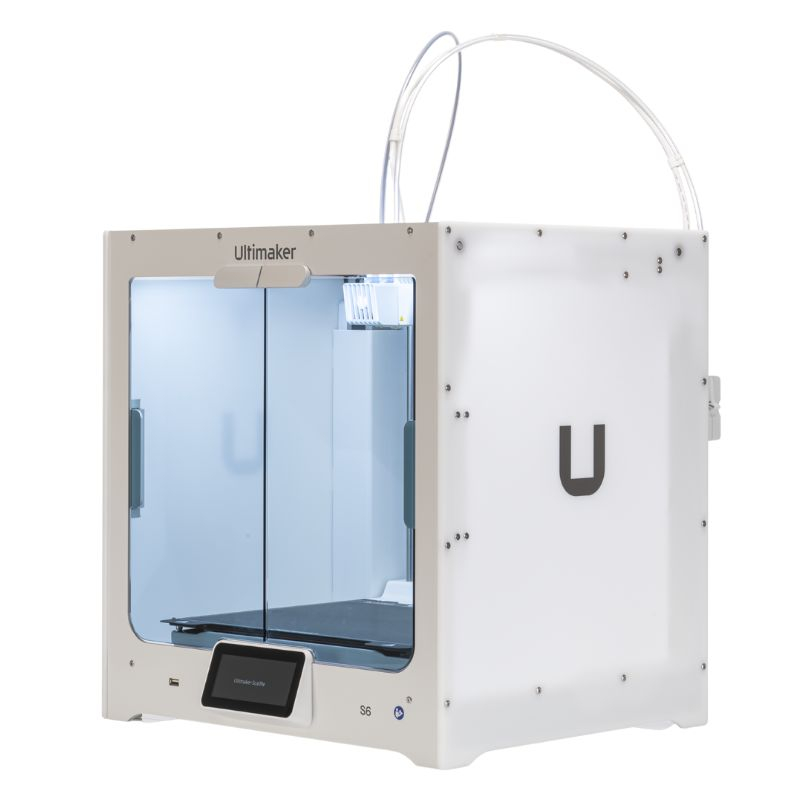

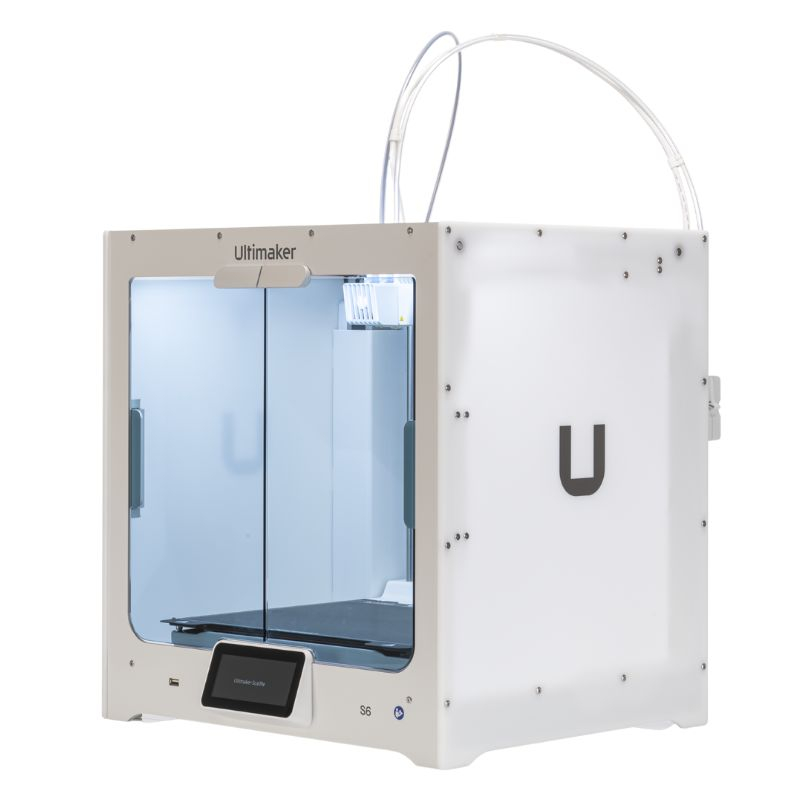

The Ultimaker S6 stands out with a unique combination of precision, power, and intelligence. Featuring new dual-drive feeders, the advanced Ultimaker Cheetah motion planner, and compatible with high-throughput Print Cores, it delivers top-level speed and precision, even on the most complex geometries.

Designed for intensive professional use, it ensures consistent results with broad material compatibility. Its heated flexible build plate, build volume of 330 x 240 x 300 mm, and full connectivity make it a robust solution for demanding production environments.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Ultimaker S6 combines reliability and precision to meet the demands of professional 3D printing, including high speeds (up to 500mm/s). Designed to provide consistent productivity, it features an intelligent dual extruder, a large build volume, and broad compatibility with technical materials.

With a build volume of 330 x 240 x 300 mm, the Ultimaker S6 can print large, complex parts while ensuring quality and repeatability. Its intuitive user interface, active leveling, and deep integration with the Ultimaker ecosystem ensure an optimized workflow. It is a robust solution for professionals seeking reliability, precision, and versatility.

Polyfab3D Expert Opinion

Certified Ultimaker and Cura Trainers

The Ultimaker S6 is the perfect solution for professionals seeking simplicity, performance, and durability. With its precise dual extrusion, compatibility with advanced materials, and design for intensive use, it integrates seamlessly into any industrial or prototyping environment. A reliable choice for demanding users.

The Ultimaker S6 is renewed with major innovations inspired by the Ultimaker S8: a new intelligent dual-drive feeder, high-performance Print Cores+, and a Cheetah motion planner.

These advancements optimize speed, precision, and reliability for professional 3D printing.

The Ultimaker S6's Cheetah motion planner optimizes print paths to ensure smooth, fast, and precise movements. This advanced algorithm reduces vibrations and improves surface quality, even at high speeds.

The Cheetah planner balances execution speed and print quality while ensuring greater reliability for complex technical parts.

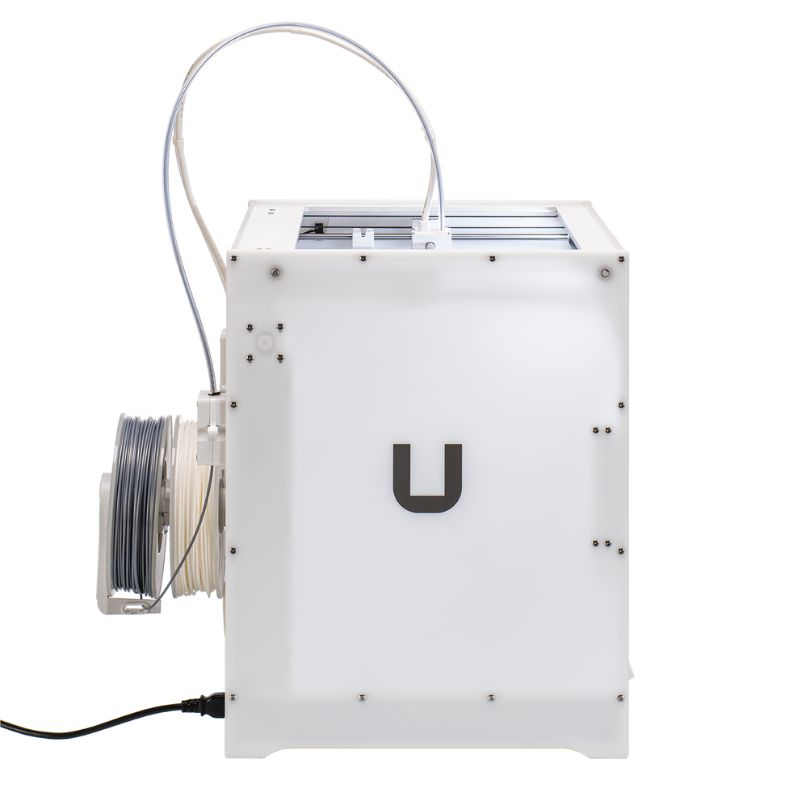

The new Dual Gear Feeder on the Ultimaker S6 ensures more reliable and precise filament feeding with its dual-drive system.

This technology improves grip and reduces slippage, guaranteeing consistent extrusion. Suitable for flexible and technical filaments, the feeder automatically adjusts tension and optimizes consistency, even during long sessions, for professional, uninterrupted results.

The new high-throughput Print Cores+ for the Ultimaker S6 enable faster printing without compromising quality. Designed to optimize material flow, these Print Cores enhance extrusion efficiency, especially for technical and composite filaments.

Their compatibility with the Ultimaker S6 ensures stable, precise performance, ideal for demanding industrial production and detailed prototypes.

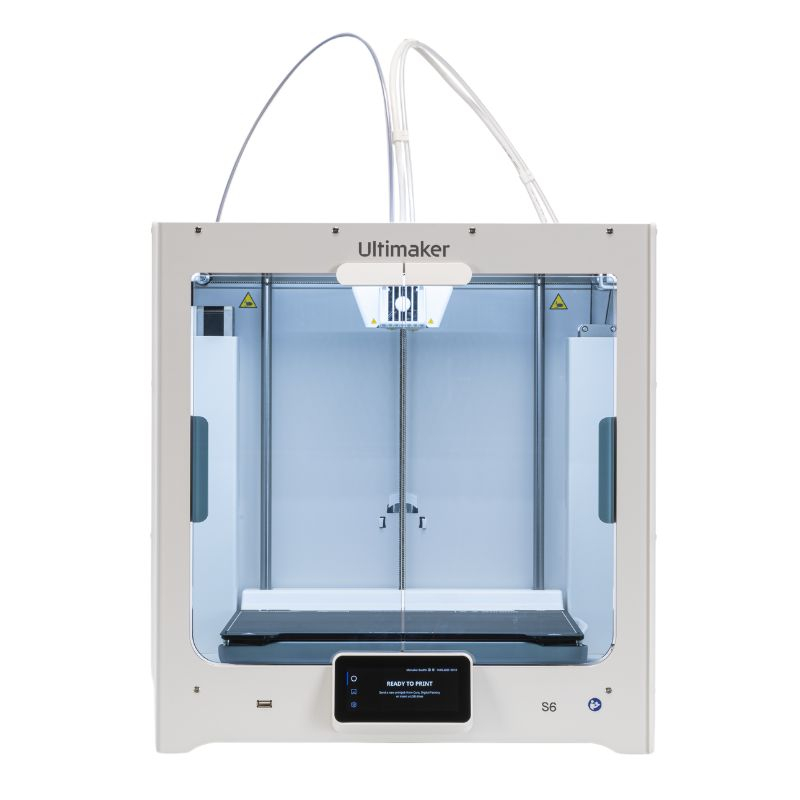

The Ultimaker S6 achieves efficient print speeds of up to 500 mm/s while maintaining excellent stability thanks to its rigid platform and precision components.

The automatic bed leveling has been redesigned to ensure optimal first layers and reduce print failures.

Its intelligent dual extrusion system allows smooth switching between materials or colors, with automated Print Core alignment, ensuring clean, precise finishes even for complex technical parts.

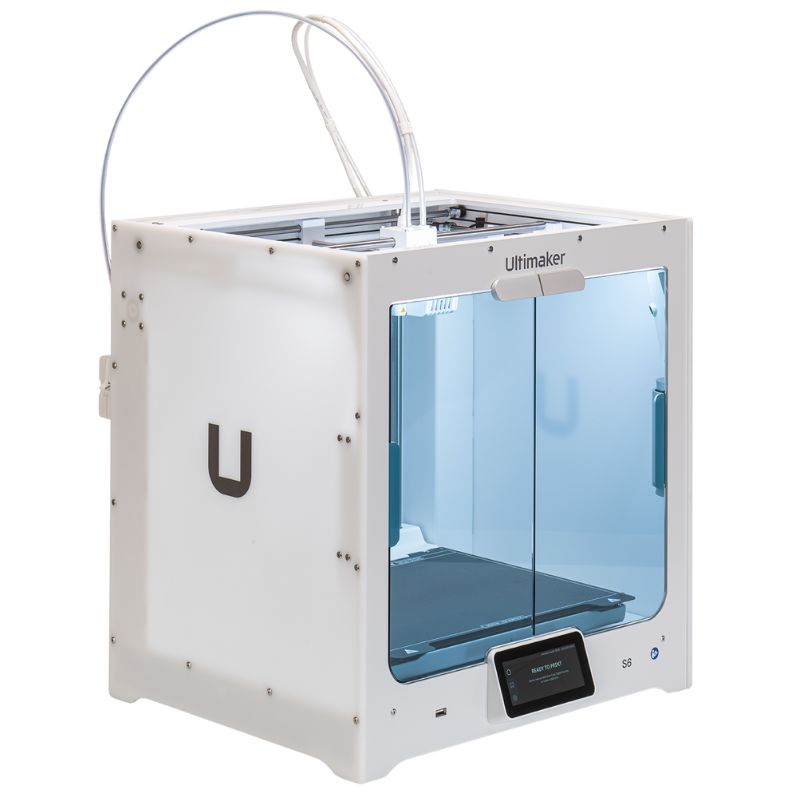

Available with a PEI flexible heated build plate up to 120°C, the Ultimaker S6 ensures excellent first-layer adhesion and easy part removal, contributing to maximum reliability for long prints. A glass build plate version is also available upon request.

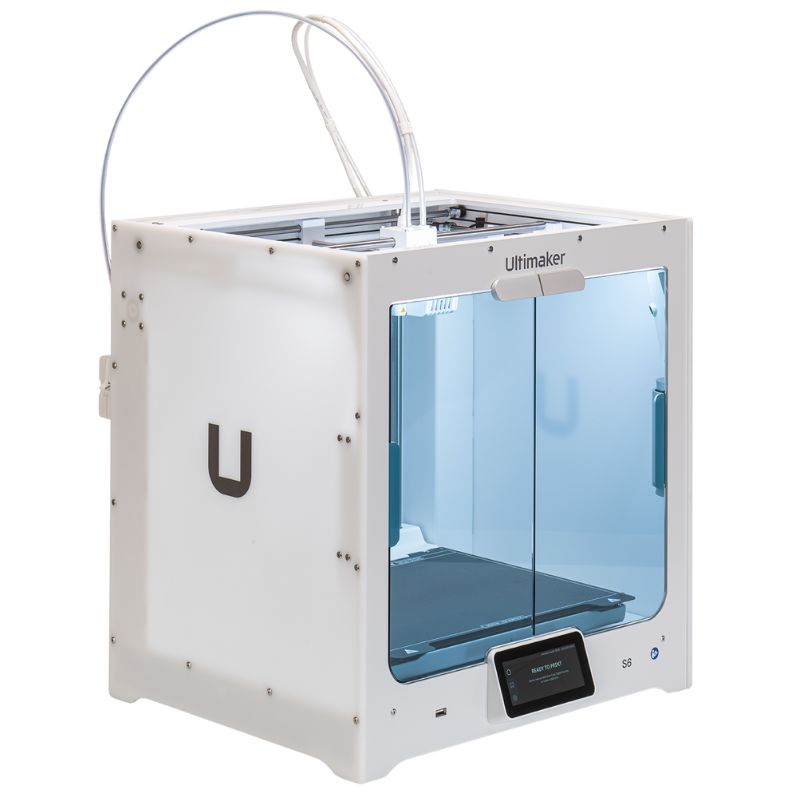

The Ultimaker S6 3D printer’s dual extrusion system facilitates printing soluble supports (PVA) or composite materials, with automated Print Core management.

Thanks to its lifting mechanisms and automatic printhead identification, transitions are fast and error-free. Ideal for technical parts with complex geometries, this system ensures exceptional surface quality even on delicate areas.

With interchangeable Print Cores and extrusion temperatures up to 340°C, the Ultimaker S6 handles a wide range of materials, from standard PLA/ABS to technical filaments like Nylon, Polycarbonate, or CPE+.

It automatically detects Ultimaker filaments via the built-in NFC chips on the spools, simplifying settings and minimizing print errors.

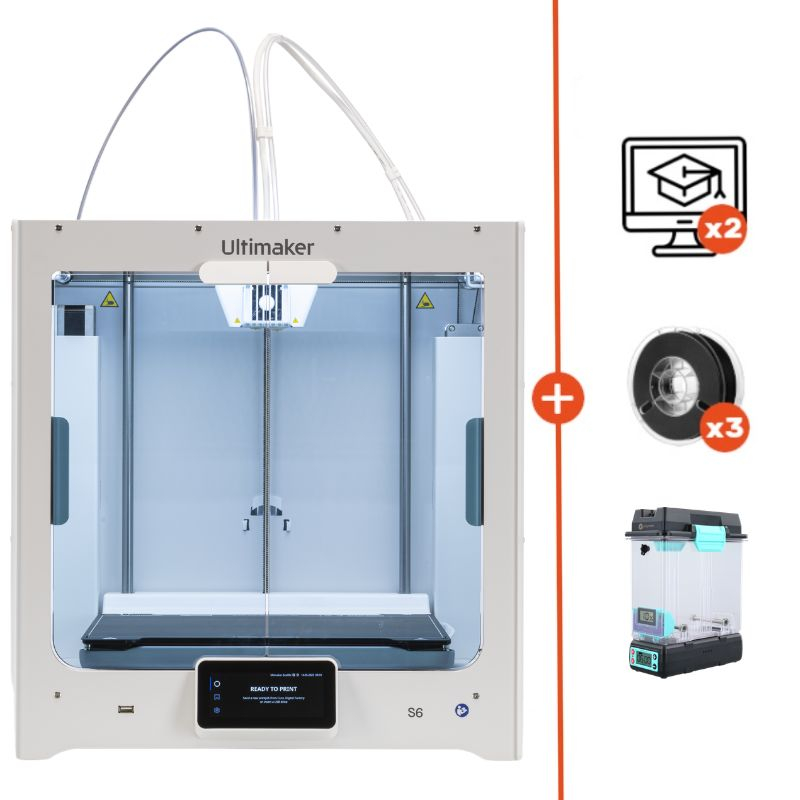

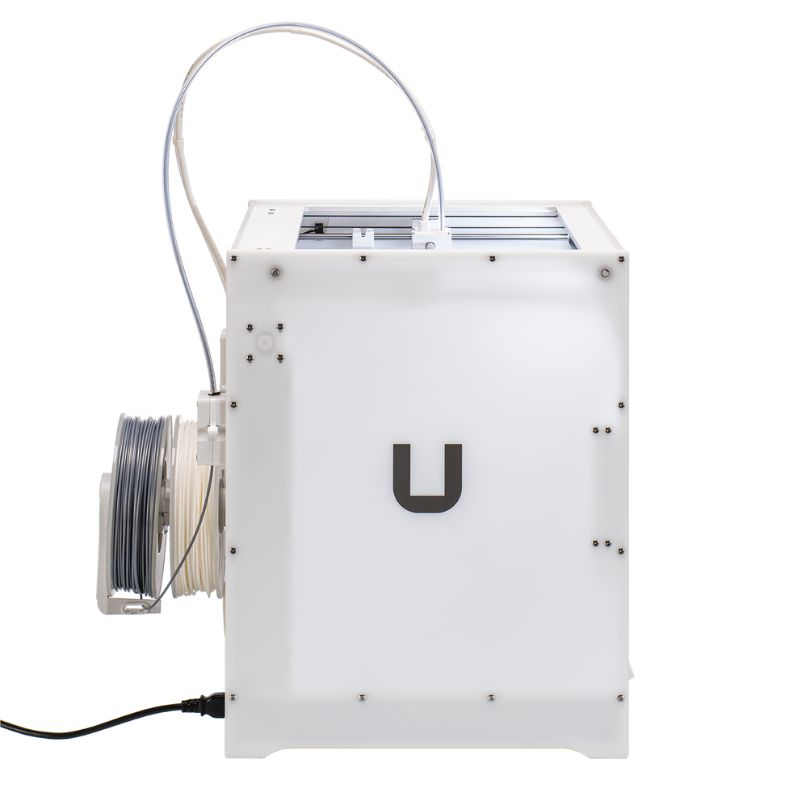

The Ultimaker S6 is compatible with the Air Manager, which filters up to 95% of ultrafine particles generated during printing, improves workplace safety and quality, and contributes to better thermal stability for sensitive materials.

The Material Station is also compatible, ensuring filament management and storage.

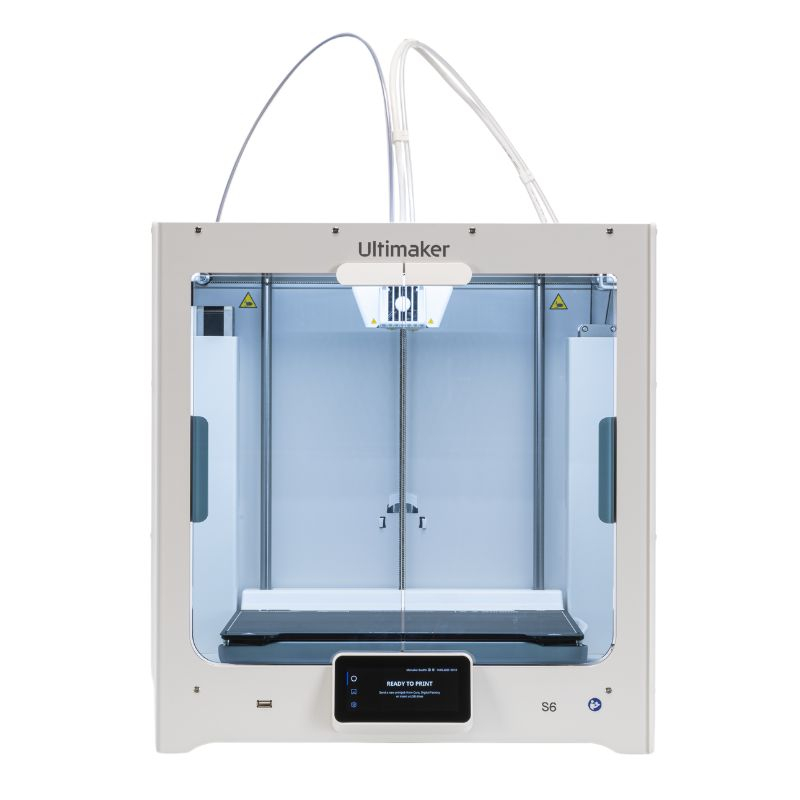

The 4.7" color touchscreen provides smooth and intuitive navigation, making print preparation and monitoring easy. On-screen instructions guide users through every step, from calibration to material change.

Combined with Cura software and the Digital Factory platform, the Ultimaker S6 offers complete remote fleet management, with real-time monitoring and advanced print scheduling.

Designed and assembled in Europe, the Ultimaker S6 embodies the brand's commitment to quality and durability. Its premium components and robust mechanical architecture make it suitable for demanding industrial environments.

It provides a reliable and long-lasting solution for professionals looking to produce series parts or complex prototypes consistently.

The Ultimaker S6 delivers a complete experience with advanced professional features that enhance quality, safety, and productivity. It stands as a key reference for design offices, R&D centers, and industrial users.

Versatile, precise, and robust, it integrates easily into all modern additive manufacturing workflows and offers a smooth and reliable printing experience daily.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

330 x 240 x 300 mm

60 microns

500 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Filament Support, Composites, ASA, PP

Specifications for Ultimaker S6

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites