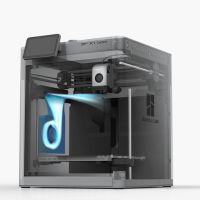

The Bambu Lab X1 Carbon Combo AMS 2 Pro offers ultra-fast, precise, and automated 3D printing. Equipped with a rigid CoreXY frame, full auto-calibration, and advanced AI algorithms, it ensures reliable and professional results.

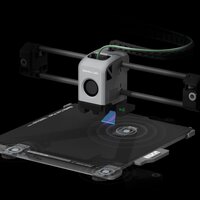

The addition of the AMS 2 Pro system enables extended multi-material management with up to 16 spools, RFID recognition, integrated active drying, and a sealed environment—ideal for technical filaments and complex prints with ease.

The product is no longer available on our website.

However ✨, here is a new arrival and the product we recommend:

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Bambu Lab X1 Carbon Combo AMS 2 Pro sets a new benchmark in professional 3D printing with a powerful combination of speed, precision, and intelligent automation. Capable of reaching up to 500 mm/s and 20,000 mm/s² acceleration, this high-end CoreXY printer delivers flawless results in record time.

Thanks to the integrated AMS 2 Pro system, it becomes a true multi-material hub, supporting up to 16 spools with RFID recognition, active drying, and intelligent filament management. Its LIDAR system, AI camera, and real-time analysis algorithms ensure constant monitoring and error-free prints.

Whether you print with PLA, PETG, TPU, PA-CF or other technical materials, the X1 Carbon Combo AMS 2 Pro offers unmatched reliability. Designed for creators, engineers, and demanding professionals, it delivers a level of automation and performance rarely seen in FDM printing.

The CoreXY motion system allows ultra-fast movements while maintaining excellent accuracy. Combined with a rigid aluminum frame and industrial-grade components, the X1 Carbon AMS 2 Pro ensures stable printing even at high speed.

This robust construction reduces vibrations and maximizes repeatability—ideal for complex parts and small series production.

The Bambu Lab X1 Carbon Combo AMS 2 Pro performs full auto-calibration before each print: bed leveling, extruder measurement, first layer inspection, and more.

It automatically adjusts extrusion pressure and axis alignment to ensure optimal results every time. Manual adjustments are no longer needed—everything is automated to save valuable time.

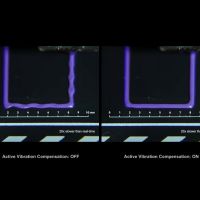

Thanks to its active vibration compensation system, the X1 Carbon with AMS 2 Pro anticipates mechanical effects at high speeds.

It analyzes and adjusts movements to reduce ghosting and resonance on printed surfaces. This dynamic control ensures high-quality finishes, even for complex high-speed prints.

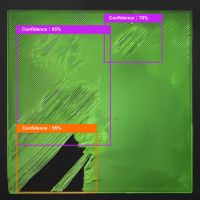

Equipped with embedded artificial intelligence, the X1 Carbon uses LIDAR to analyze the first layer quality and detect extrusion issues in real time.

In case of problems, it can pause the print or notify the user. These algorithms greatly reduce errors and ensure a high success rate, even for long or technical prints.

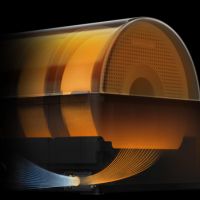

The AMS 2 Pro system allows up to 4 modules to be connected simultaneously, each handling 4 spools, for a total of 16 materials available.

Bambu Lab filaments are automatically recognized via RFID tags, making print profile management easier. Spool switching is fast, accurate and fully automated.

The Bambu Lab AMS 2 Pro features integrated active drying up to 65 °C to keep moisture-sensitive filaments in optimal condition. Its airtight chamber and brushless motors ensure outstanding reliability and longevity.

Its intelligent management reduces jamming risks and optimizes filament flow for every print.

The X1 Carbon Combo is compatible with a wide range of standard and technical materials.

From PLA to PETG, including flexible TPU and composites like PA-CF / GF, it meets the needs of professionals and advanced makers alike. It also handles soluble supports like PVA for complex parts.

With a nozzle that heats up to 300 °C and a bed reaching 120 °C, the X1 Carbon supports high-temperature polymers.

This thermal range allows printing of technical materials like PC, nylon or composites, while ensuring excellent first layer adhesion.

The magnetic flexible PEI plate makes part removal easy after printing. It provides excellent hot adhesion while being easy to clean.

This plate is removable and replaceable, allowing it to be adapted to different filament types or desired finishes.

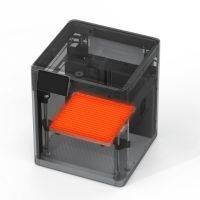

The enclosed chamber of the X1 Carbon improves thermal stability for materials sensitive to warping. It is equipped with an activated carbon filter that captures volatile compounds, protecting the user and the environment.

This confined design favors printing technical materials under optimal conditions.

The integrated LIDAR sensor scans the first layer in high precision to detect any potential defects.

It automatically adjusts the nozzle height or pauses the print if a problem occurs. This system guarantees perfect adhesion and solid foundations, preventing errors in the first minutes.

The built-in camera allows remote print monitoring, generating timelapses, and detecting defects like spaghetti (extrusion in mid-air).

In case of anomalies, the printer can automatically stop or alert the user via the mobile app.

The user interface features a smooth and intuitive 5″ touchscreen. Connected via Wi‑Fi, the X1 Carbon can be controlled through Bambu Studio (PC) or Bambu Handy (mobile).

The Cloud integration allows remote print start, progress monitoring, and profile management from anywhere.

In case of a power failure, the X1 Carbon can resume printing from where it stopped.

This feature ensures maximum safety, especially for long or critical prints, preventing unnecessary filament and time loss.

With its high speed, exceptional precision and many automated features, the Bambu Lab X1 Carbon establishes itself as a benchmark in professional 3D printing. The Combo version with AMS 2 Pro goes even further thanks to an ultra-efficient material management system.

The AMS 2 Pro enables automated multi-material printing with RFID recognition, built-in active drying and a sealed environment, ideal for technical filaments. Up to 16 spools can be managed simultaneously with great reliability. For users demanding versatility and productivity, this machine offers unmatched time savings and quality.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

256 x 256 x 256 mm

500 mm/s

PLA, ABS , PETG, Flexible, Nylon, ASA, PC-ABS, PLA-CF, PA-CF

Specifications for Bambu Lab X1 Carbon Combo AMS 2 Pro

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites