- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

-

- 🎯 Services dedicated to professionals

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14-day return

3D Dental Solutions

Complete dental 3D solutions, integrating printers, biocompatible materials, and software. They enable the production of prostheses, surgical guides, orthodontic or implant models with precision, speed, and consistency. The digital workflow is optimized for reliable additive manufacturing within labs or practices.

Resin tank of resin Arch Kit Optical Polish V2, SprintRay Pro 95, Pro 95S

- -35%

10K Ortho Model Water Washable Resin Forshape Premium - 1 kg

- -20%

- -€10.00 excl. VAT

3D Dental Solutions

3D printing has revolutionized digital dentistry by enabling the direct production of dental components (models, prosthetics, guides, orthodontic devices) with speed, precision, and full integration within dental practices. 3D dental solutions encompass the entire ecosystem needed to implement an integrated workflow, from scanning to the final piece.

Components of a 3D Dental Solution

Scanning / 3D Acquisition: The intraoral impression or tomography (CBCT) serves as the starting point. High-precision 3D scanners are necessary to accurately capture dental morphology, without distortion.

Modeling / Preparation Software: The raw data must be cleaned, segmented (teeth, gums, bone structures), and transformed into usable geometry. It is at this stage that corrections (thicknesses, pull areas, supports) are defined.

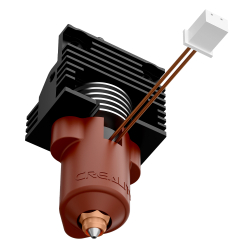

3D Printing (Additive Manufacturing): Commonly used in dentistry, they ensure excellent surface resolution and precise control of successive layers.

Post-processing & Finishing: After printing, the pieces must be cleaned, hardened (cured), and possibly polished or sandblasted. Quality control (dimensional inspection, strength test) is essential to ensure compliance.

Integration & Clinical Validation: 3D dental workflows must be validated according to standards (e.g., ISO 10993 for medical materials) and integrated into the existing processes of the laboratory or practice. Traceability, batch management, and documentation are key elements.

Benefits of 3D Dental Solutions

Reduced lead times: Models or prosthetics can be produced in a few hours instead of days.

Repeatability & Precision: Fit deviations are reduced through precise process control.

Flexibility & Customization: Parts are personalized without the need for a traditional prosthetic mold.

Cost Optimization: Less waste, fewer manual interventions, fewer returns.

Traceability & Regulatory Compliance: Validated solutions ensure compliance with medical requirements.

Why choose Polyfab3D?

By adopting a complete and validated 3D dental solution, a dental laboratory or practice can position itself at the forefront of digital dentistry: produce faster, with consistent quality, and reduce error margins. Each system component, from scanning to finishing, must be carefully chosen.

We invite you to explore our printers, resins, post-processing equipment, and to contact us for personalized assistance in setting up your 3D dental workflow.