The Bambu Lab H2D Combo is an ultra-high-performance 3D printer, combining dual extrusion, multi-material and multi-color printing, all at high speed and compatible with numerous technical materials.

Fast, versatile, and intuitive, the Bambu Lab H2D Combo stands out as an essential solution for professionals and enthusiasts.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Bambu Lab H2D Combo is designed to push the boundaries of additive manufacturing, combining dual-material/multi-color 3D printing with advanced print optimization technologies.

With its dual extrusion system, ultra-rigid aluminum frame, high-temperature hotend, and advanced filament management system, the H2D Combo allows professionals, designers, and enthusiasts to explore new creative possibilities. Equipped with a suite of smart sensors, onboard AI, and precise control over temperature and vibrations, this machine ensures reliable prints, high detail, and compatibility with the most demanding materials.

Included: This H2D Combo version comes with the AMS 2 Pro filament management system.

With the H2D Combo, create objects with advanced features by combining flexible and rigid materials in a single print. This capability allows the integration of hinges, joints, or interlocking structures that are impossible to achieve with traditional methods.

By alternating high-performance materials with standard plastics, it is also possible to optimize costs while maintaining reinforced areas at critical points.

Thanks to its dual extrusion system, the H2D Combo allows for printing soluble or specialized supports without sacrificing surface quality. No more difficult-to-remove supports or imperfections after removal: prints are cleaner, more precise, and require less post-processing.

This system also optimizes material consumption by reducing purging and filament reloading.

The use of independent dual nozzles reduces filament waste between color changes. Thanks to intelligent algorithms, transition management is optimized to minimize waste and speed up the printing process.

This allows you to create parts with colored details without the excessive wait times associated with traditional filament purging systems.

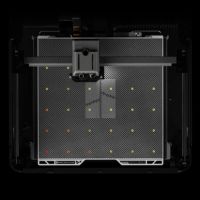

The H2D Combo integrates a magnetic induction automatic calibration technology, eliminating the need for tedious manual adjustments.

This contactless system adjusts the nozzle positioning with extreme precision, ensuring perfect layer overlap and smooth printing. It provides reliable and repeatable calibration, without tools or user intervention.

The H2D Combo uses a high-precision calibration plate, the Vision Encoder, combined with a 5-micron resolution optical system to dynamically correct the movements of the print head.

This guarantees ultra-precise positioning, consistent print quality, and exact dimensions across the entire bed, without the need for repeated adjustments. Vision Encoder sold separately.

The advanced nozzle detection technology allows for automatic alignment of the two extruders before each print. This contactless calibration eliminates alignment errors and ensures uniform print quality across the entire piece.

With built-in sensors measuring the pressure at the nozzle, the H2D Combo adjusts the extrusion flow in real-time to achieve smoother and more uniform surfaces. The edges of the parts are sharper, and the details are more precise, no matter how complex the model is.

The Bambu Lab H2D Combo automatically analyzes and corrects vibrations in the print head before each session. This ensures smooth surfaces and increased stability, even for complex prints.

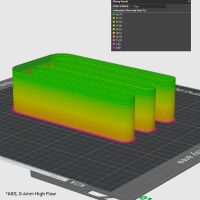

With a print volume of 350 × 320 × 325 mm, the Bambu Lab H2D Combo allows for large-scale projects without size constraints.

Whether for 3D printing large parts or laser engraving (with the compatible model) on large objects, its extended workspace paves the way for ambitious designs.

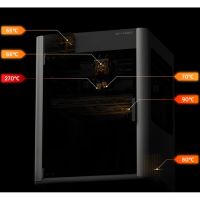

The printer is equipped with a hotend capable of reaching 350°C and an active heating system for the chamber up to 65°C. This advanced thermal regulation prevents warping of materials and ensures excellent layer adhesion.

Thus, it supports technical materials like PEEK, PEI, and reinforced nylon, ideal for demanding industrial applications.

Thanks to a specially designed high-flow hotend, the Bambu Lab H2D Combo ensures fast and continuous printing at 600 mm/s without any slowdown due to flow restrictions. This system guarantees a constant filament flow, with a flow rate reaching 40 mm³/s.

With its clip-on nozzle changing system, there's no need to disassemble the extruder or unplug any wires: the nozzle can be replaced in seconds, allowing for quick and efficient maintenance without interrupting production.

The DynaSense extruder uses advanced PMSM (Permanent Magnet Synchronous Motor) architecture for precise extrusion control.

Thanks to real-time torque and resistance analysis at 20 kHz, it dynamically adjusts filament feeding and detects signs of wear or clogging before they affect printing.

Equipped with a hardened steel extruder and nozzle, the Bambu Lab H2D Combo is built to handle abrasive and composite materials such as carbon fiber and glass fiber.

The strength of its aluminum frame minimizes micro-flexing and vibrations to maintain high precision, even during high-speed and large-format prints.

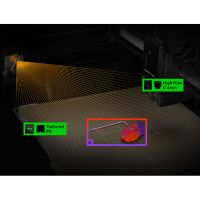

The Bambu Lab H2D Combo is equipped with an AI-powered camera featuring a macro lens for ultra-precise extrusion monitoring. This system constantly analyzes filament deposition, instantly detecting material buildup, filament inconsistencies, and extrusion faults.

This technology enables real-time control, minimizing errors and improving print reliability.

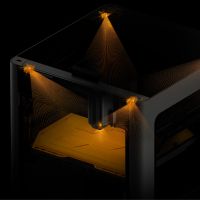

Before each print, the H2D Combo performs a full diagnostic check of the printer and print area using its advanced vision system. This automatic checklist includes three key steps:

The H2D Combo integrates complete material flow monitoring through an intelligent network of 15 sensors (notably via the AMS 2 Pro), which continuously analyze various parameters: feed rate, filament tension, exact filament tip location, extruder thermal conditions, and dynamic extrusion pressure.

This advanced system enables proactive filament management, reducing the risk of failed prints.

The Health Management System (HMS) 2.0 of the H2D Combo functions as a true automatic diagnostic system, similar to those found in modern cars.

Using sensors and cameras, it identifies potential printing issues and provides detailed solutions to resolve them quickly.

The H2D Combo comes with an advanced thermal regulation system, constantly monitoring the temperature of all heating elements using intelligent sensors.

This closed-loop control automatically adjusts the temperature to prevent sudden fluctuations and ensures stable and optimal operation, while extending the lifespan of the heating components.

The H2D Combo's Adaptive Airflow system relies on three adjustable air vents and a dynamic air intake, offering advanced control of airflow within the print chamber.

This system intelligently adjusts the flow between internal and external circulation, ensuring effective filtration of laser fumes (for the Laser model) and 3D printing emissions, while optimizing internal temperature for ideal printing conditions.

The H2D Combo is equipped with flame sensors that can immediately detect any fire outbreak inside the printing chamber. It can emit an audible alert and notify the user for a prompt intervention.

The printer is built with flame-retardant materials, integrated into the structure of the printing chamber. This design helps reduce fire risks by providing effective passive protection.

The Bambu Lab H2D Combo offers smooth cloud connectivity, enabling remote control from any connected device. For sensitive environments, it also provides a fully offline mode, ensuring complete physical security by isolating the printer from the network.

Users can send files, manage prints, and update firmware without needing internet access. For advanced users and integrators, the H2D Combo features a developer mode allowing access to the MQTT port.

The Bambu Lab H2D Combo pushes the boundaries of 3D printing. With its ultra-rigid architecture and advanced dual extrusion system, it combines versatility, speed, and precision. Its generous print volume of 350 × 320 × 325 mm and compatibility with high-performance materials make it a top choice for both professionals and enthusiasts. Combined with the AMS 2 Pro system, the H2D Combo stands out as a complete solution that simplifies the printing process.

Thanks to innovative technologies such as active vibration compensation, smart filament management, and automatic calibration, every print is accurate and reliable. If you’re looking for a printer capable of dual-material and multi-color printing, the Bambu Lab H2D Combo is a complete and powerful solution.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Trusted Distributor: Polyfab3D offers a selection of the best brands, ensuring quality products, access to the latest innovations, and dedicated technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

350 x 320 x 325 mm

10 microns

600 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Filament Support, Composites, PVA, ASA, PP, PLA-CF, PA-CF

Specifications for Bambu Lab H2D Combo

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites