- Pre-order

The Bambu Lab P2S Combo is a closed CoreXY 3D printer designed for demanding professionals. With a print volume of 256 x 256 x 256 mm and a nozzle temperature reaching up to 300 °C, the Bambu Lab P2S Combo offers wide compatibility with various materials.

Its integrated AMS 2 Pro system, 5-inch touchscreen, and enclosed chamber with filtration ensure optimal use and consistent print quality.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The Bambu Lab P2S Combo is a closed CoreXY desktop 3D printer designed for professionals, design offices, and advanced makers. It combines speed, precision, and reliability.

With a build volume of 256 x 256 x 256 mm and a nozzle temperature reaching up to 300 °C (PLA, ABS, PC, TPU), the Bambu Lab P2S Combo is a versatile tool for prototyping and the production of functional parts.

The AMS 2 Pro system automatically manages filaments, allowing continuous multi-material printing without user intervention. It detects filament levels, switches spools, and ensures a stable feed, reducing print errors and interruptions.

Perfect for complex multi-material prints and users looking for a smooth, automated workflow.

The 5-inch touchscreen allows users to control the printer, adjust settings, and monitor print progress in real time.

Its clear menus and responsive interface simplify navigation and make it easy to access all of the P2S Combo’s functions.

The enclosed, filtered chamber protects users from emissions and enables safe printing of technical materials such as ABS and PC.

It maintains a stable temperature, improves layer adhesion, and reduces warping, ensuring consistent, reliable results.

With a build area of 256 x 256 x 256 mm, the P2S Combo can produce medium to large parts.

This capacity meets the needs of prototyping, small-batch production, and creative projects, offering enough space for both testing and manufacturing functional parts.

The Direct Drive extruder with a PMSM motor ensures precise, consistent filament feeding, even with flexible or technical materials.

Its extrusion force of up to 8.5 kg maintains a stable flow, reducing the risk of clogging or under-extrusion for uniform, high-quality prints.

The 0.4 mm hardened steel nozzle is built to handle abrasive filaments such as PETG, nylon, or composites.

It maintains its precision and durability, ensuring reliable printing performance even with demanding materials while reducing wear and maintenance.

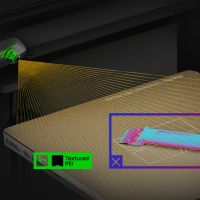

The textured PEI heated bed offers excellent first-layer adhesion and minimal warping.

This durable surface and the heated enclosure allow for stable, deformation-free prints, ensuring easy part removal and a professional finish.

The built-in AI system monitors prints in real time and automatically detects common issues. It can correct them or notify the user, reducing waste and failed prints.

This feature enhances overall reliability and consistency, allowing users to focus on creation rather than constant monitoring.

The automatic calibration system detects and adjusts the first layer to ensure perfect adhesion and maximum precision.

This simplifies setup and minimizes human error, ensuring each print starts under optimal conditions for consistent, professional-quality results.

The P2S Combo offers USB, Wi-Fi, and Bluetooth connectivity, allowing remote control and real-time supervision.

Users can integrate the printer into a collaborative environment, manage multiple printers simultaneously, and access live updates and notifications.

The P2S Combo supports a wide range of materials: PLA, ABS, TPU, PETG, Nylon, PC, and composites.

This flexibility enables users to tackle diverse projects, experiment with different materials, and meet advanced prototyping or production needs.

Bambu Studio is the dedicated software for the Bambu Lab P2S Combo, featuring an intuitive interface and advanced functions to optimize every print. It enables efficient material management, real-time monitoring via an integrated camera, and seamless compatibility with the AMS 2 Pro for automated multi-material printing.

The software also simplifies firmware updates and integration with other Bambu Lab tools, providing a smooth and professional user experience.

As a 3D printing expert, I highly recommend the Bambu Lab P2S Combo to professionals looking for a reliable, fast, and versatile printer. Its CoreXY motion system ensures outstanding precision, while the enclosed chamber and AMS 2 Pro system guarantee consistent print quality.

Additionally, the integration of AI-based error detection is a major advantage, reducing failures and optimizing workflow. In short, the P2S Combo is a smart investment for any business or workshop aiming to produce high-quality parts efficiently and consistently.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

256 x 256 x 256 mm

10 microns

600 mm/s

PLA, ABS , PETG, Flexible, Nylon, PVA, ASA, PLA-CF, PET-CF, PA-CF

Specifications for Bambu Lab P2S Combo

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites