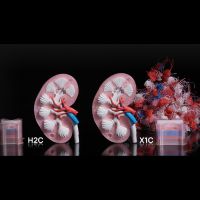

The Bambu Lab H2C AMS Combo is the professional 3D printer that eliminates waste during multi-material printing. Based on the revolutionary Vortek System, it swaps complete hotends in seconds, enabling clean filament transitions and minimal purging.

Combined with the AMS 2 Pro, the Bambu Lab H2C handles up to seven different colours or materials without waste, allowing the creation of complex functional parts (PA, PC, TPU) in a single process.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

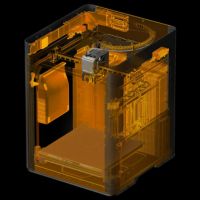

The Bambu Lab H2C AMS Combo is far more than a simple dual-extrusion system; it marks a technological breakthrough thanks to the integration of the Vortek System. This setup is specifically designed for engineering offices and professionals seeking to master multi-material and multi-colour printing (up to 7 filaments) with unprecedented efficiency.

The key innovation lies in its radical handling of colour changes: by swapping the entire hotend, the Vortek system reduces purging to an absolute minimum, turning a wasteful process into a true economic advantage.

Thanks to its stable enclosure and advanced extruder, this model consistently delivers functional parts of high quality, even with demanding technical polymers such as PA, PC or TPU.

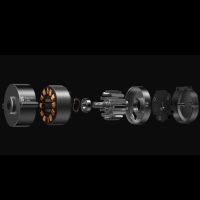

Unlike single-nozzle systems that require long purges to avoid colour contamination, the Vortek system performs a full hotend replacement.

This method ensures perfectly clean material transitions and drastically reduces filament waste — a decisive factor for professionals looking to optimise material cost and reliability.

Speed is essential in production environments. Vortek integrates advanced induction heating technology that allows the new nozzle to reach working temperature in only eight seconds.

This remarkable time saving on every filament change directly reduces overall multi-material print cycles, optimising machine productivity.

The H2C Combo comes with the AMS 2 Pro system, enabling fully automated filament switching. The combined intelligence of Vortek and AMS allows up to seven filament sources.

The onboard algorithm can even calculate the optimal pairing between filaments and available hotends to further minimise purge waste.

The Vortek rack can accommodate up to six interchangeable hotends, each dedicated to a filament. Its clever design ensures that this versatility does not reduce the build volume.

The H2C thus maintains a generous and practical construction area — essential for large parts or batch production.

Each extruder is equipped with a permanent magnet servo motor (PMSM) delivering a maximum extrusion force of 10 kg.

This motor exceeds the force of traditional stepper motors by 70%, ensuring stable flow even during ultra-fast printing or with challenging filaments, while integrating real-time jam detection.

Thanks to Vision Encoder technology, the Bambu Lab H2C achieves exceptional positioning accuracy under 50 microns.

This high-resolution movement ensures that fine details and tight tolerances on complex parts, including bi-material interfaces, are maintained consistently and reproducibly throughout the machine's lifetime.

The H2C chamber is actively heated to 65°C and its hardened steel nozzles can reach up to 350°C.

This controlled thermal environment is essential for warp-prone filaments like ABS, PC, or composites, optimizing layer adhesion and strengthening the structural integrity of technical parts.

One of the major challenges, aligning the dual heads, is handled autonomously. The Bambu Lab H2C uses induction calibration to adjust nozzle offsets with remarkable 25 µm precision.

This feature eliminates time-consuming manual adjustments and ensures perfect material or color fusion on every print.

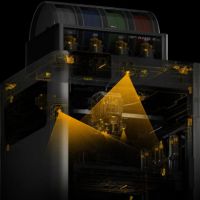

The Bambu Lab H2C integrates a comprehensive diagnostic system based on 59 sensors and AI-assisted vision. This intelligent network continuously monitors the extrusion process to detect faults in real time.

It also performs a "pre-flight scan" before each print, ensuring safe and reliable print starts.

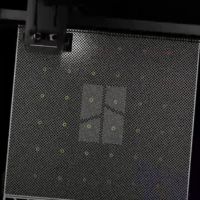

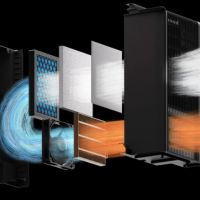

Workshop safety is ensured by a triple filtration system (G3 pre-filter, HEPA H12, and coconut shell activated carbon).

This filtration is essential to minimize VOC and fine nanoparticle emissions from high-temperature filaments, maintaining a healthier working environment.

The Vortek system hotends are made of hardened steel. This superior hardness is a prerequisite for using abrasive composite filaments (carbon or glass fiber-filled).

It ensures prolonged wear resistance and stable extrusion performance, crucial for printing durable mechanical parts.

Passive safety is enhanced by constructing the print chamber with UL94 V-0 rated materials.

This fire-resistant construction provides robust protection against fire hazards, a critical consideration for professional environments and long unattended prints.

Bambu Studio is the comprehensive software platform designed to unlock the full potential of the Bambu Lab H2C Combo. It offers an intuitive interface for multi-material task setup, handling Vortek’s complexity seamlessly. The slicer ensures perfect synchronization of filament profiles and hotends via the cloud.

For maximum flexibility, professionals benefit from remote control and a fully offline mode option for applications requiring the highest security and complete network isolation.

The Bambu Lab H2C Combo is undoubtedly a highly sophisticated production machine. The engineering around the Vortek system represents a significant breakthrough, resolving the historical compromise between multi-material versatility and filament waste. This model, combining high-precision mechanics (servo motor, 50 µm accuracy) and intelligent software management, is the ideal tool for applications where performance and reliability are paramount.

The ability to produce integrated parts with diverse material properties, without the inconvenience of purging, places the Bambu Lab H2C firmly among the most relevant professional 3D printers on the current market.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

300 x 320 x 325 mm

10 microns

1000 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Composites, PVA, ASA, PP, PLA-CF, PET-CF

Specifications for Bambu Lab H2C AMS Combo

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites