Nylon, or polyamide, is a thermoplastic material known for its strength, durability, and excellent wear resistance. Originally developed for industrial applications, it has gradually made its way into the world of 3D printing, where it stands out thanks to its excellent mechanical properties and versatility.

Whether for functional parts, mechanical components, or highly durable prototypes, nylon filaments are a top choice. However, there are various types of nylon: PA6, PA12, PA612, reinforced versions, ESD-safe, etc.

Each type of filament meets specific requirements, with particular constraints regarding printing and storage.

The different types of nylon filaments

Differences between PA6, PA12 and PA612

The three main nylon families used in 3D printing are PA6, PA12, and PA612. Their chemical structures, moisture behavior, and mechanical and thermal properties vary significantly.

PA6 (polyamide 6) is derived from a single monomer. It is the most rigid and mechanically resistant of the three. It offers excellent wear and tensile resistance, with a high melting temperature (around 220–230 °C).

However, it is highly hygroscopic: it can absorb more than 3% ambient moisture, which affects its dimensional and mechanical properties if not properly dried.

PA12, on the other hand, has a longer chain structure. It is much less sensitive to moisture, with absorption below 0.5%. This makes it more stable during printing and more flexible than PA6. Its elongation at break is higher, making it suitable for parts that must withstand shocks or deformation.

Its melting point is lower (178–180 °C), making it easier to process and reducing the risk of warping.

PA612 is a copolymer that combines the characteristics of PA6 and PA12. It offers excellent stiffness, comparable to PA6, while maintaining low moisture sensitivity and good dimensional stability.

This balance makes it a high-performance material for demanding environments, particularly in warm and humid conditions. It also retains its mechanical properties better after thermal aging or exposure to fluids.

In summary:

- PA6: very rigid, wear-resistant, but highly hygroscopic.

- PA12: more flexible, easier to print, moisture-stable.

- PA612: the best of both worlds, ideal for durable technical parts.

Reinforced nylons: glass fiber and carbon fiber

To meet even greater mechanical requirements, certain formulations include short or long fibers. Composite nylon reinforced with glass fiber gains increased rigidity, thermal stability, and dimensional consistency, especially for structural parts.

Carbon fiber nylon offers an exceptional strength-to-weight ratio. Carbon fibers added to the polymer enhance tensile and flexural strength while making the material lighter. It is particularly popular in the automotive, robotics, and sports industries.

Technical Nylons: ESD, Filled, and Modified

Certain special formulations are designed to address specific challenges:

ESD nylon (Electro Static Dissipative) is developed to prevent the buildup of static electricity. It is used for sensitive electronic components or in ATEX environments.

Also worth mentioning is Nanovia PA Food Industry: a nylon filament designed to meet the requirements of the food industry. Certified for food contact, it is suitable for producing parts in hygienic environments or in direct contact with food products.

Fiberon Nylon Filament Range

Developed to meet the highest standards of industrial 3D printing, the Fiberon™ range from Polymaker includes reinforced technical nylon filaments for advanced applications. Each filament combines a high-performance polyamide base with glass fibers, carbon fibers, or functional additives to enhance mechanical strength, dimensional stability, or even ESD properties.

Polyfab3D offers a complete selection of the Fiberon filament range, with spools in various sizes (500g and 3kg) suitable for both production and functional prototyping.

Applications of Nylon Filaments

Nylon filaments are highly versatile. They are widely used in industrial sectors where mechanical strength, durability, and chemical stability are essential.

Common applications include:

- – Gears, bushings, and moving mechanical parts.

- – Automotive components exposed to heat, vibrations, or fluids.

- – Drone and robot parts, lightweight yet strong.

- – Technical mounts for electronic equipment, especially using ESD-safe nylon.

They are also used in functional prototyping, allowing for real-world testing of parts well before moving to injection molding.

How to Print Nylon Filament

Printing nylon requires a certain level of expertise. The material is sensitive to humidity, prone to warping, and requires high temperatures.

While specific parameters vary depending on the formulation, in general:

- Extrusion temperature: between 240 and 270 °C for PA6 or PA612, and around 240–250 °C for PA12.

- Bed temperature: between 80 and 100 °C to prevent first layer detachment.

- Cooling fan: low or turned off, as excessive cooling can cause poor inter-layer adhesion.

The printing speed should remain moderate to ensure good surface quality and optimal layer adhesion, although some next-generation nylons are optimized for high-speed printing.

Of course, reinforced nylons will have different printing parameters. That’s why we recommend following the instructions provided on each filament’s product sheet.

Hardware requirements for printing Nylon

Not all 3D printers are compatible with nylon. To print this type of filament, the equipment must meet several criteria:

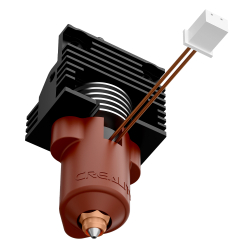

- Extruder capable of reaching at least 260–270 °C, or even higher for reinforced versions.

- Abrasion-resistant nozzle, such as hardened steel or ruby, especially for fiber-filled filaments.

- Specific adhesion surface: PEI, BuildTak, Magigoo PA, or glue sticks like UHU may be necessary to reduce warping.

- A closed or heated chamber helps stabilize ambient temperature and limits deformation during printing, especially with PA6.

Moisture: an enemy not to underestimate

Nylon is highly hygroscopic: it quickly absorbs moisture from the air, which can cause bubbles during extrusion, a rough matte surface finish, and significant mechanical property degradation.

Before printing, it is essential to dry the filament for several hours:

- – In a convection oven at 70–80 °C for 6 to 12 hours.

- – In a dedicated filament dryer.

- – Or by storing it permanently in a filament storage/drying system with desiccant packs or an automated system.

Even a few hours out of its container can saturate nylon filament spools with moisture. It is highly recommended to place the filament back into a dry system between each printing session.

Annealing and post-processing of nylon filament

Nylon can benefit from thermal annealing after printing. This improves its crystalline structure, reduces internal stresses, and increases thermal and mechanical resistance.

The process involves:

- – Heating the part to a temperature between 70 and 95 °C for 30 to 60 minutes.

- – Allowing it to cool slowly in a closed environment to avoid thermal shock.

This treatment is especially useful for technical parts or those subjected to significant mechanical stresses. It is strongly advised to follow the specific recommendations of each filament provided by the manufacturer.

Conclusion

Nylon is a demanding material but offers remarkable performance. Its mechanical strength, durability, thermal and chemical stability make it a valuable ally for producing functional parts with 3D printing. By mastering printing parameters, storage conditions, and post-processing options, you can get the best out of this versatile material.

Whether you choose a rigid PA6, a flexible and easy-to-print PA12, or a high-performance PA612, each nylon filament has its own specificities and uses. The key is to know them well to exploit them to their full potential.

✅ Why Choose Polyfab3D?

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

Contact us now for a personalized recommendation tailored to your needs, budget, and ambitions.