Multicolor 3D printing allows you to create aesthetically complex and functional parts, but it generates an unavoidable phenomenon: purge. Purge refers to the deliberate extrusion of material to clean the nozzle before or during printing.

While essential for ensuring quality and preventing defects such as color mixing or clogs, it can lead to significant material waste.

Causes of waste during purges

Purge methods are effective in ensuring a clean print, but they generate material that does not contribute to the final object. In some cases, the amount of purged material can reach several tens of grams.

Several factors explain why purge can account for a significant part of 3D filament consumption:

- Machine design: Single-nozzle 3D printers require more purge when changing color or material, as all residual material must be expelled.

- Slicer settings: purge tower height, purge line length, and extrusion volume at the start of each print are often set conservatively, generating more waste.

- Part design: objects with more color transitions require more purges. Complex, detailed multicolor models are particularly wasteful.

- Material type: materials such as TPU or other flexible polymers stick more to the nozzle and require extra purging for a clean flow.

- Nozzle condition: a clogged or poorly maintained nozzle requires more purge to avoid streaks or failures.

How to reduce purge-related waste

Optimize slicer settings

Fine-tuning purge settings is crucial. You can reduce purge tower height, line length, or extrusion volume at print start. Some slicers allow injecting purge directly into the infill of the part or a secondary object, minimizing pure waste.

Strategic print planning

Planning the print sequence can reduce transitions and thus purges. Group same-color areas, plan homogeneous bases before adding colored details, and place multiple parts together to reduce purge cycles.

Regular machine maintenance

A clean nozzle reduces necessary purge length. Cleaning, brushing, or unblocking the nozzle with a fine needle minimizes residue, reducing waste.

Use painting to avoid color changes

When visual precision doesn’t require native multicolor printing, it’s better to print the part in a single color and paint it afterward.

This method eliminates purges between materials, reduces filament use, and offers greater artistic freedom, especially for gradients or special effects.

Find our tips to master every step of painting your parts for unique and highly detailed pieces.

Give purge waste a second life

Purge blocks and strands can be reused instead of discarded. By melting them into 3D silicone molds, you can create simple objects like handles, coasters, or decorative pieces.

This hands-on approach turns unavoidable waste into creative raw material and reduces overall environmental impact.

Hardware innovations to limit purge

New machine generations offer solutions to reduce waste:

- Progressive mixing heads: allow gradual color changes or gradients, limiting purge.

- Smart slicers: calculate exact purge amounts needed for each transition, reducing lost filament.

- Tool change systems: some machines use a head per material or color, eliminating the need to purge at each transition.

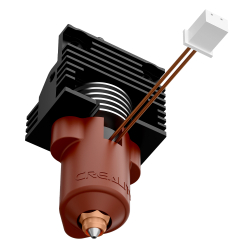

For example, the Snapmaker U1 stands out with its 4 independent heads system, drastically reducing purges during color changes.

Each extruder manages its own material, avoiding nozzle cleaning extrusion. This approach improves efficiency, reduces waste, and enhances color precision.

Result: clean multicolor parts, without unnecessary material loss or bulky purge structures on the bed.

Towards more sustainable 3D printing

Reducing purges is not only an economic matter: it is a step toward more responsible and sustainable technology. Purged materials can be avoided or reused. Good practices combined with technical innovation allow complex parts to be produced while minimizing waste.

A proactive and technical approach, combining precise settings, planning, and regular maintenance, is essential to reduce waste without compromising the quality of multicolor 3D prints.

✅ Why Choose Polyfab3D?

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

Contact us now for a personalized recommendation tailored to your needs, budget, and ambitions.