- Pre-order

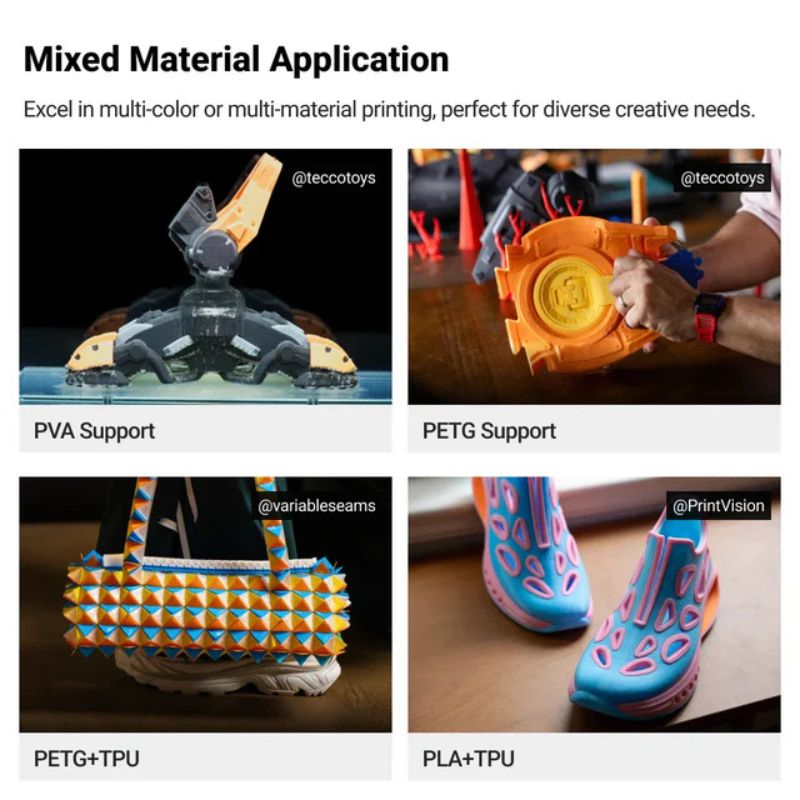

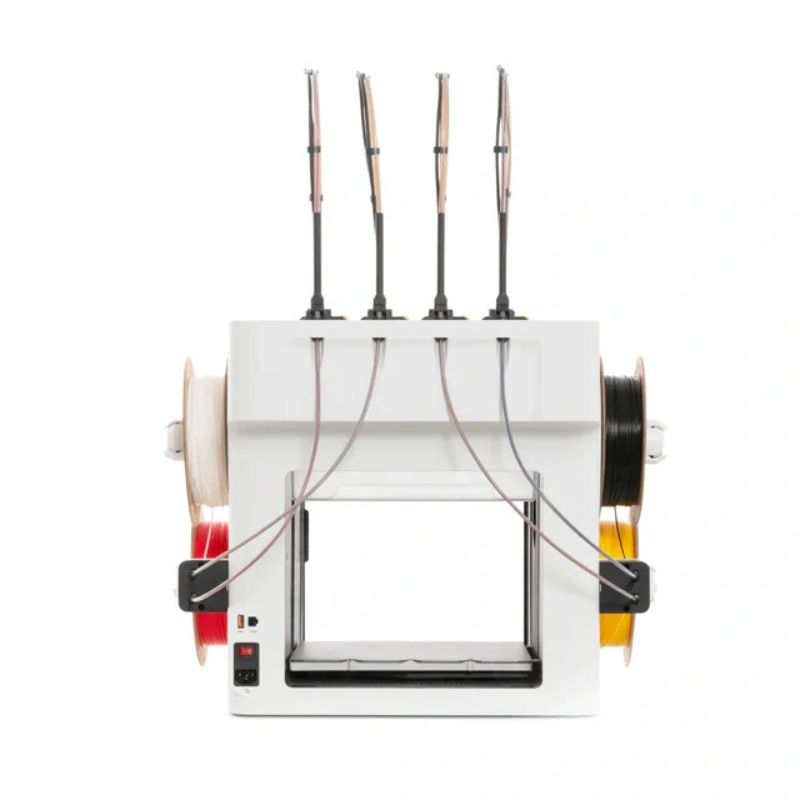

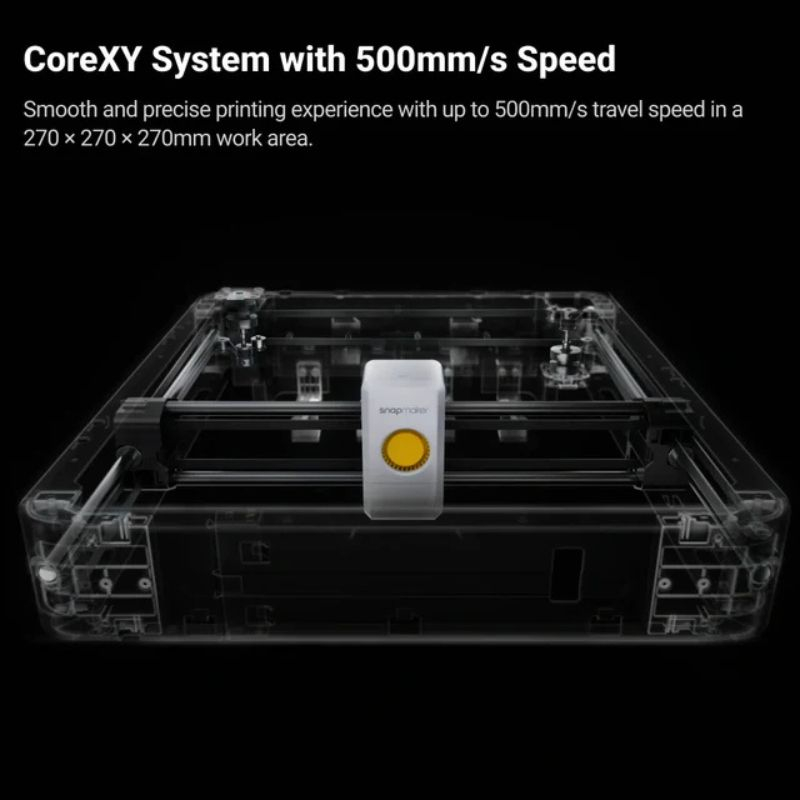

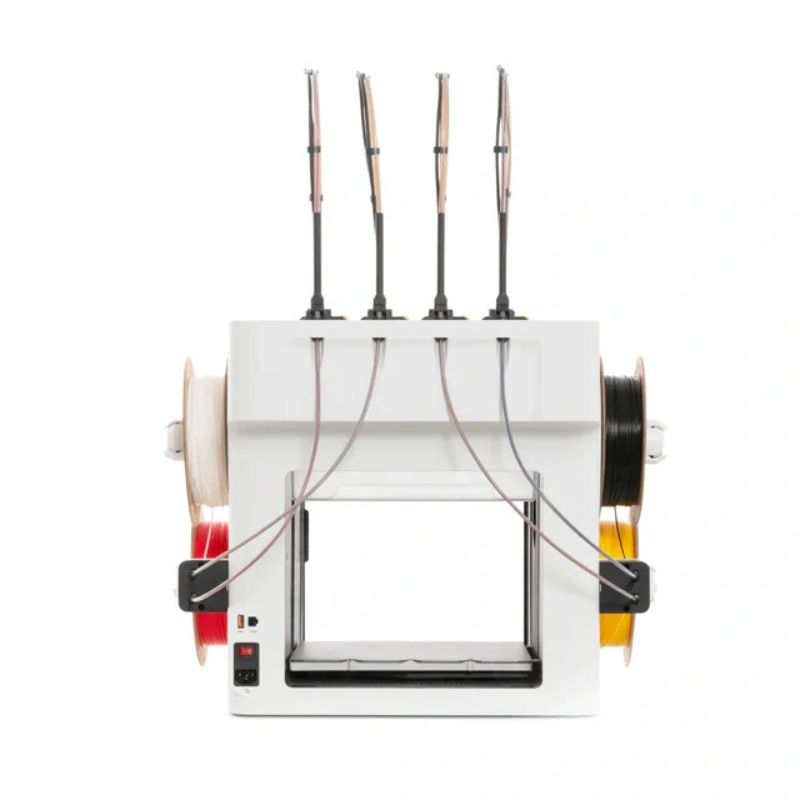

The Snapmaker U1 is an advanced 3D printer with 4 independent heads, allowing multi-color and multi-material printing without excessive purging. Its CoreXY structure, automatic compensations, and ultra-precise calibration (< 0.04 mm) ensure fast, reliable, and high-fidelity prints. With a build volume of 270 × 270 × 270 mm, Wi-Fi/LAN/USB connectivity, and dedicated Orca software, the U1 is designed for demanding professionals.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

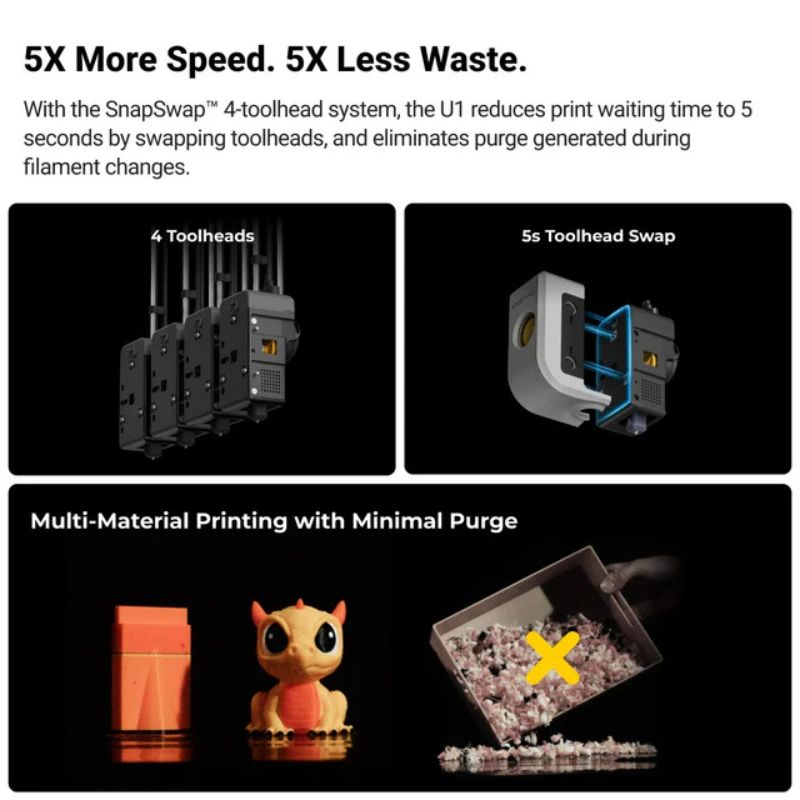

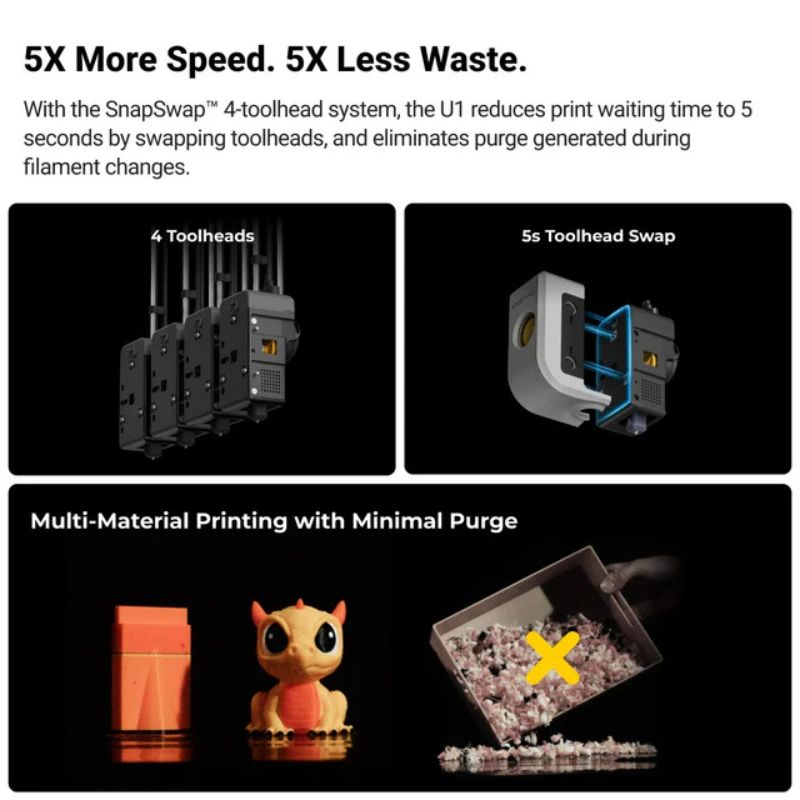

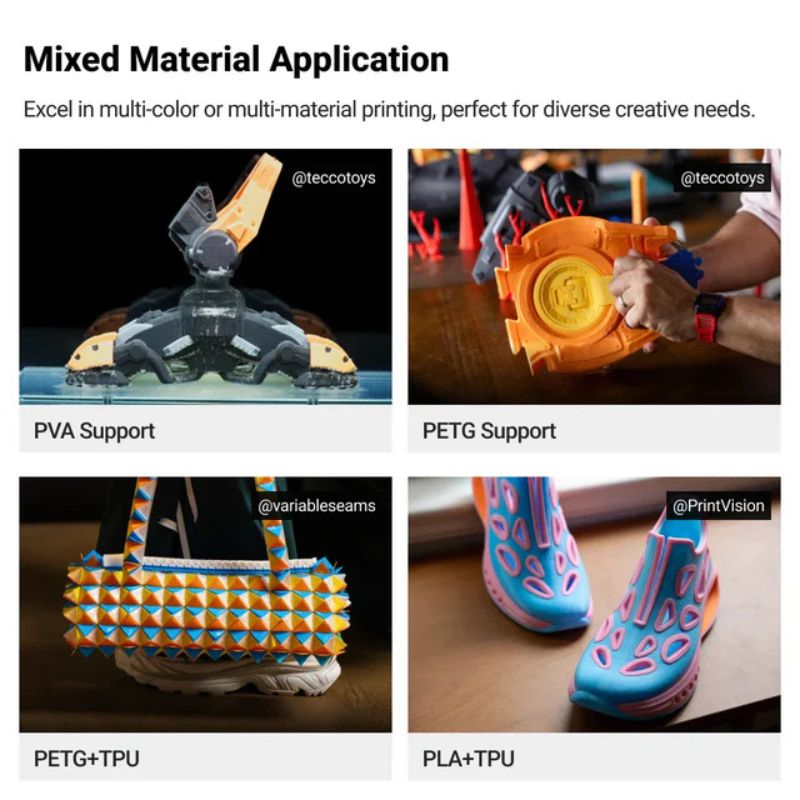

The Snapmaker U1 is an innovative 3D printer designed for demanding professionals and enthusiasts. It features four independent heads capable of combining different colors and materials in a single print, significantly reducing filament waste. Filament changes take only a few seconds.

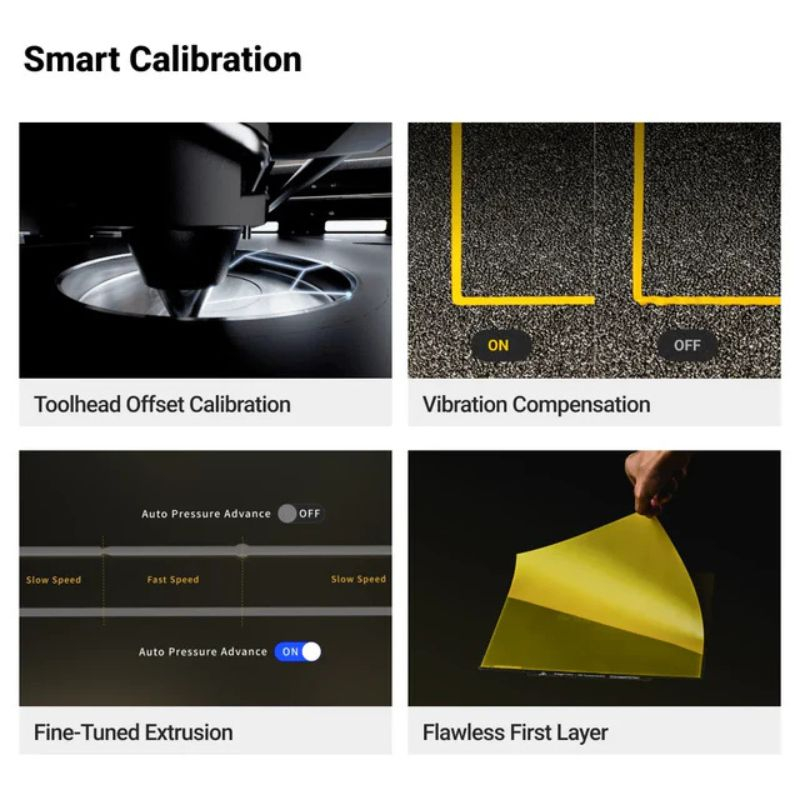

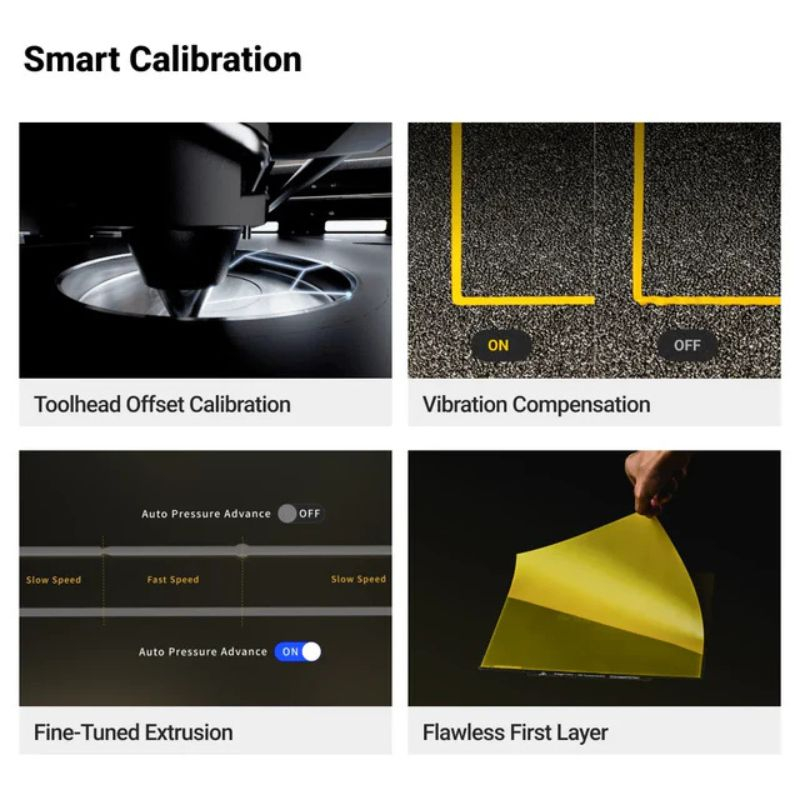

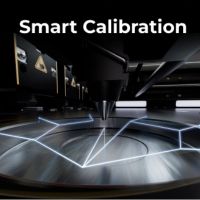

Its rigid CoreXY structure and advanced compensation algorithms, including input shaping and pressure advance, ensure deviations below 0.04 mm when switching heads. This mechanical stability allows the production of complex prototypes and functional parts with consistency and reliability.

Compact yet modular, the U1 also features automatic calibration and correction for an efficient and professional workflow.

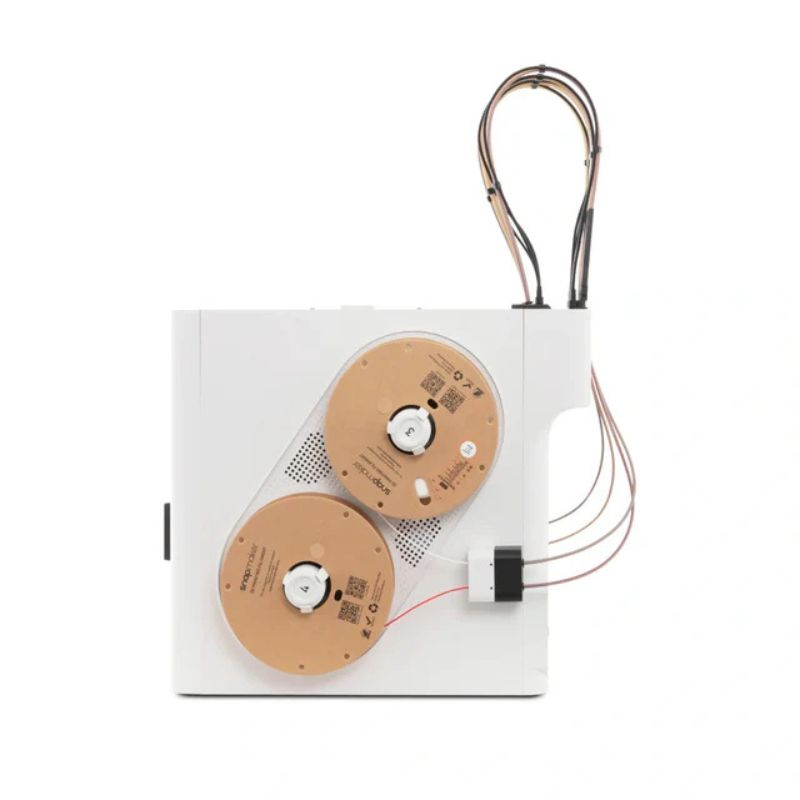

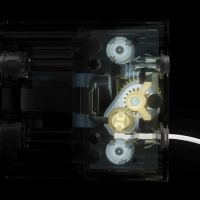

Thanks to the SnapSwap™ system, the U1 can change filament in just 5 seconds without excessive purging. This automation allows fast multi-color and multi-material prints while reducing waste, ideal for workshops and design offices seeking an efficient and consistent production workflow.

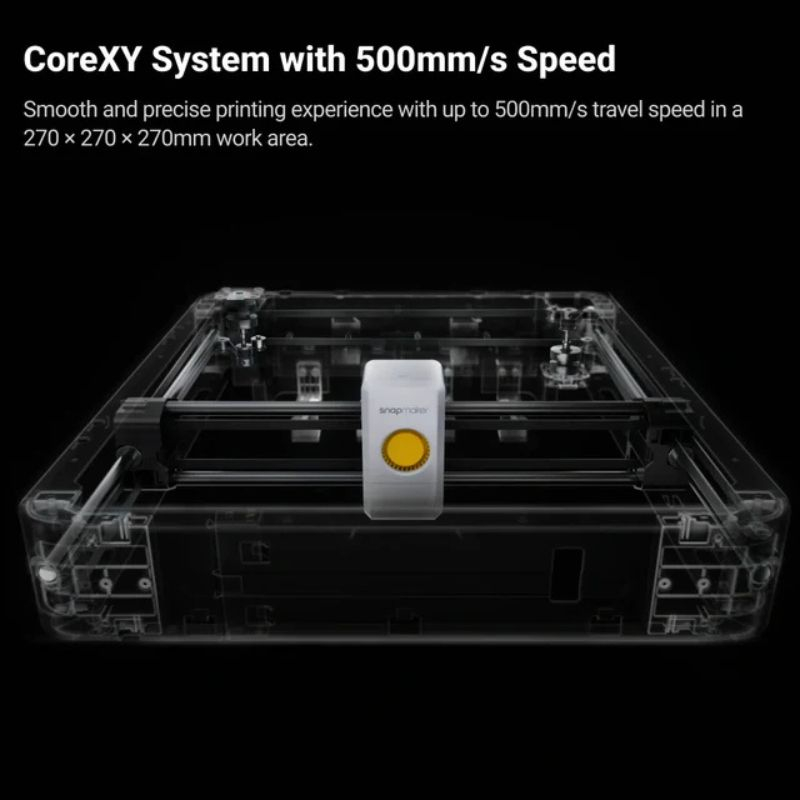

The CoreXY mechanics and high-performance motors allow the U1 to reach speeds up to 500 mm/s and accelerations of 20,000 mm/s². This combination of speed and stability guarantees clean parts even during long prints while maintaining good surface quality.

The U1 uses advanced sensors and compensatory calibration algorithms to align each head with an offset below 0.04 mm. This prevents layering errors and ensures consistent quality across all prints, even for complex multi-material models requiring high precision.

The 270 × 270 × 270 mm volume allows the creation of large prototypes or multi-part assemblies. It provides flexibility for all projects, from technical parts to conceptual or decorative objects, optimizing production time with larger prints.

Each head has a direct drive extruder reaching 300 °C, allowing the printing of many materials such as PETG, TPU, PVA, or PLA. This precise temperature control ensures perfect layer adhesion for your prints.

The heated bed reaches up to 100 °C, ensuring reliable adhesion for all warp-prone materials. It keeps parts stable during printing, reduces warping risks, and is particularly useful for technical filaments requiring constant temperature.

The Snapmaker U1 ensures ultra-precise alignment between heads, below 0.04 mm. This precision is essential for multi-material or multi-color prints, where each layer must perfectly match the previous one, delivering clean, professional results.

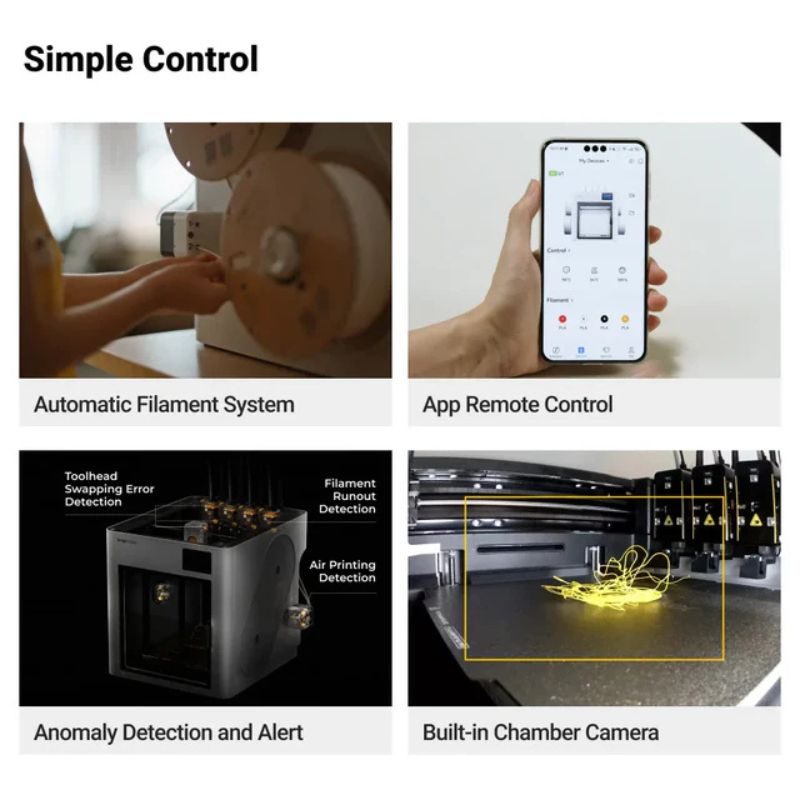

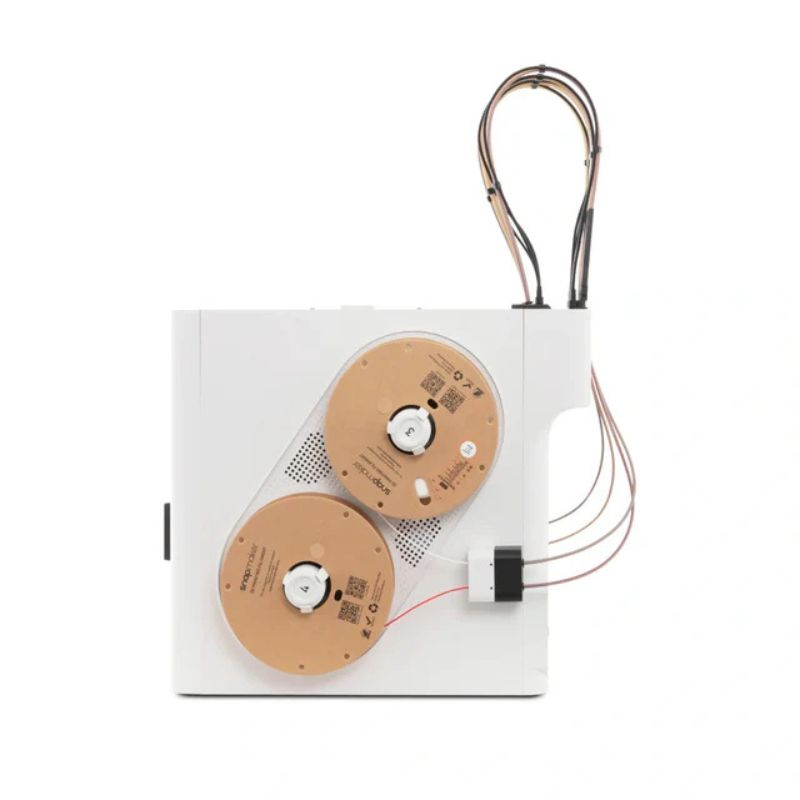

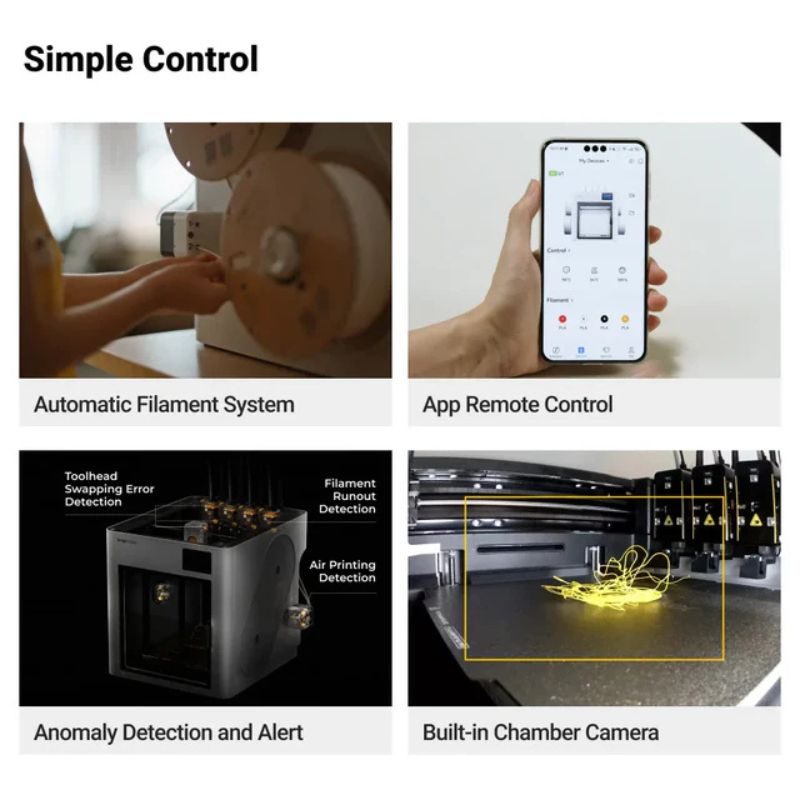

The RFID system automatically detects compatible spools, facilitating filament changes and material management. This reduces time spent identifying filaments and ensures the printer uses the correct temperature and speed profiles for each material, guaranteeing reliable and precise prints.

The built-in camera monitors prints in real time and automatically detects issues like spaghetti or obstructions. Coupled with real-time alerts, it allows quick problem correction, avoiding wasted time and filament.

The U1 can be controlled via Wi-Fi or USB, enabling remote management and real-time print monitoring. Combined with Orca Slicer and the Snapmaker app, this connectivity offers full control of the printing process and simplifies managing multiple machines in a professional workshop or office.

Printing on the Snapmaker U1 relies on Snapmaker Orca Slicer, providing optimized profiles for multiple heads and technical materials. Coupled with the Snapmaker app, it allows remote monitoring, real-time adjustments, and automatic timelapse generation.

Multi-color transitions are smooth and simplified.

The Snapmaker U1 represents an excellent balance between performance, automation, and controlled cost. The multi-head system reduces waste and enables smooth transitions. At high speed, input shaping ensures remarkable surface quality.

Ideal for multi-material and multi-color prototyping, it remains reliable and precise for professional use.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

270 x 270 x 270 mm

100 microns

500 mm/s

PLA, PETG, Flexible, PVA

Specifications for Snapmaker U1

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites