The Vortek System from Bambu Lab represents a major evolution in the way nozzles dedicated to different materials are changed and managed.

By replacing the traditional extruder head concept with a modular architecture, the Vortek System allows switching between distinct materials without purging, with high mechanical precision and repeatability rarely seen in this type of system.

Vortek System: Rethinking Material Transitions

One of the main challenges of classic multi-material systems is purging: wasted material, lost time, and potential cross-contamination. The Vortek System overcomes this by using individual hotends, each dedicated to a single material or color. The result is simple: no material needs to be extruded between transitions, as it is the hotend itself that is replaced.

This tooling logic is reminiscent of automatic tool changers used in CNC machines. Here, the same principle is applied to filament extrusion, with a strong emphasis on reliability, induction heating, and contactless communication.

Technical Understanding and Architecture of the Vortek System

To fully understand what this technology changes, it is essential to examine its three main pillars: contactless communication, induction heating, and the design of dedicated hotends. These elements work together to create a coherent, high-performance, and durable system.

Fully Contactless Communication

The nozzles do not plug into a physical connector. They communicate via a contactless protocol. This choice eliminates several potential failure points: oxidation, misalignment, bent pins, or friction points prone to wear. By removing these constraints, the Vortek System gains robustness and longevity.

Induction Heating

Induction is key to fast heating. Each hotend can be heated very quickly. Temperature regulation synchronizes the heated zone with the heatsink, preventing thermal overshoot and allowing precise transitions between sensitive or demanding materials. This heating method also ensures stable performance in warm environments without risk of temperature drift.

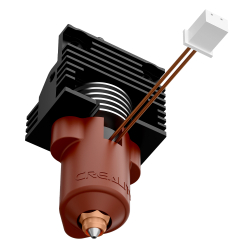

Dedicated and Compact Hotends

Each nozzle is designed as an independent tool: lightweight, compact, and optimized to reduce inertia. One nozzle = one material (up to 7 materials). This approach enables instant changes and eliminates one of the main drawbacks of classic multi-tool systems: cross-contamination. Dedicated hotends ensure full control over successive deposit quality.

Vortek System: Automated Nozzle Change Process

The change sequence is automated and follows an industrial-grade, highly precise protocol. The system selects the appropriate nozzle, detaches the current one, retrieves the next, locks it in place, and validates the setup using various sensors.

Steps of Automated Change

- Identify the required nozzle.

- Automatically detach the current nozzle.

- Retrieve the new nozzle from its holder.

- Verify alignment and communication.

- Resume printing immediately without purging.

This sequence, repeated thousands of times, highlights the importance of contactless communication and mechanical miniaturization. The transition time becomes negligible, greatly improving productivity.

Benefits of the Vortek System for Users

The advantages of the Vortek System impact both the final print quality and overall process efficiency. These benefits are tangible and technical rather than marketing claims.

Key Benefits

- No purge waste: clean transitions with zero material loss.

- Truly independent materials: no cross-contamination between colors or properties.

- Easy maintenance: a faulty hotend can be replaced without complex disassembly.

- Automated management: no manual intervention between steps.

- Reduced downtime: almost instant changeovers.

- Compatibility with heated enclosures: essential for demanding materials.

- Extended lifespan due to absence of contact pins.

Vortek System: Multi-Materials and Advanced Color Management

The Vortek System allows managing up to seven hotends without purging. This means you can combine seven distinct materials, properties, or colors in a single print while maintaining the quality of each area.

Zero-Purge Operation

When avoiding waste is a priority, simply assign one material per nozzle. Transitions are completely clean, with no residual filament, as no material needs to be purged between tools.

Extended Options for Highly Colorful Projects

For complex projects requiring more color variations, the system can go further with software strategies. The idea is simple: use minimal purging only when necessary, enabling up to twenty different shades. This compromise is advantageous when visual output is a priority.

The new Bambu Lab H2C represents a milestone as it natively integrates the Vortek System. This machine introduces a completely redesigned multi-material approach, fully leveraging nozzle change capabilities without purging.

Thanks to its optimized architecture, it allows the use of up to seven dedicated thermal tools while maintaining remarkable stability. The Bambu Lab H2C thus becomes the reference platform to explore the full potential of this innovative technology.

Vortek System: Field Feedback and Practical Applications

Early feedback emphasizes consistency: the reliability of nozzle changes is the major strength of the Vortek System. While some multi-material systems may be sensitive to alignment or cleaning, this one works as an independent tool, ready to use. Workshops running long production cycles highlight:

- drastically reduced downtime;

- better repeatability between parts;

- less manual intervention on nozzles;

- the ability to integrate multiple functional materials in a single geometry without mixing risk.

Where this system truly stands out is in ease of use despite its sophisticated architecture. Automatic changeovers become a reliable routine rather than a stress point.

Conclusion

By completely rethinking material management, the Vortek System provides an elegant and durable solution to a longstanding problem: how to switch from one material to another without purging, without loss of precision, and without human intervention. The modular approach, contactless communication, and induction heating form a solid technical foundation designed to last and adapt to advanced workflows.

This technology opens the way to new, cleaner, faster, and more versatile workflows. For demanding users, whether experienced individuals or prototyping workshops, it represents a genuine advancement.

✅ Why Choose Polyfab3D?

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

Contact us now for a personalized recommendation tailored to your needs, budget, and ambitions.