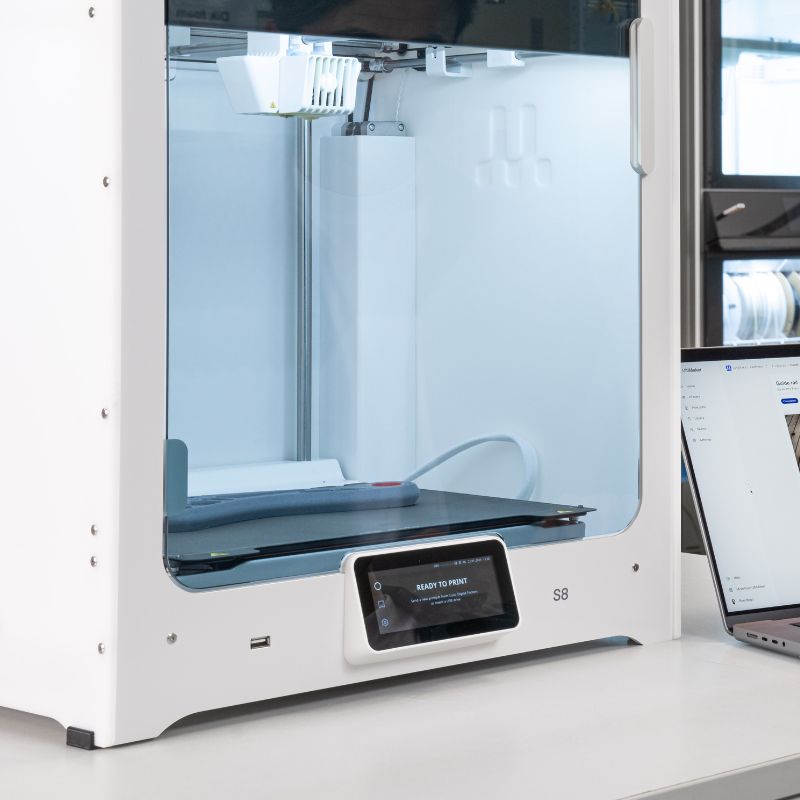

The UltiMaker S8 3D printer offers increased productivity thanks to its advanced UltiMaker Cheetah motion planner, new high-flow print cores, and improved feeder. It can print complex multi-material parts with exceptional precision and speed (up to 500 mm/s).

Designed for reliable performance 24/7, it integrates into the UltiMaker ecosystem and is compatible with a wide range of materials. With a build volume of 330 x 240 x 300 mm, the UltiMaker S8 is the ideal tool for professionals seeking speed, quality, and flexibility in 3D printing.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The UltiMaker S8 pushes the boundaries of professional 3D printing with enhanced productivity and high-speed printing. Thanks to its new UltiMaker Cheetah motion planner, high-flow Print Cores, and redesigned feeder, it achieves print speeds up to 4 times faster than previous models while ensuring flawless quality.

Its large 330 x 240 x 300 mm print volume provides increased flexibility for prototyping, functional parts, and serial production. Compatible with a wide range of materials, it ensures reliable and repeatable printing. Its intuitive interface, advanced automatic calibration, and optimized software ecosystem streamline the workflow. The UltiMaker S8 is the ideal solution for professionals demanding speed, reliability, and precision.

Polyfab3D Experts' Opinion

Certified Ultimaker and Cura Trainers

The UltiMaker S8 is the perfect choice for professionals looking for speed, reliability, and versatility. With printing up to 4x faster than other UltiMaker models, a large print volume, and a complete ecosystem, it enables precise part production in record time. Its Cheetah motion planner and optimized feeder ensure smooth and controlled prints, even with technical materials. A strategic investment for maximum productivity.

The UltiMaker S8 achieves impressive printing speeds of up to 500 mm/s, with optimized accelerations up to 50,000 mm/s² thanks to its advanced new firmware.

The combination of the UltiMaker Cheetah motion planner and the new high-flow Print Cores ensures smooth extrusion (35 mm³/s) and optimal thermal control. This technology maintains excellent resolution while significantly reducing printing times.

The extrusion temperature can reach up to 340°C, and the redesigned feeder ensures constant and precise material feeding, minimizing errors and guaranteeing an impeccable surface quality.

The UltiMaker Cheetah motion planner optimizes printing paths by reducing vibrations and improving acceleration management. It dynamically adjusts speeds based on complex geometries, ensuring precise extrusion even at high speeds.

This advanced system significantly saves time, making it ideal for environments requiring fast production cycles without compromising part quality.

The new high-flow Print Cores of the UltiMaker S8 feature a redesigned nozzle and optimized heating to ensure faster and more consistent extrusion. Their improved design reduces material flow resistance, allowing for an extrusion flow of 35 mm³/s and higher printing speeds without quality degradation.

Available in different sizes, these Print Cores adapt to user needs, whether for technical materials or high-volume production.

The UltiMaker S8 feeder has been redesigned to meet the demands of high-speed printing. Its reinforced mechanism ensures constant pressure on the filament, reducing the risk of under-extrusion and clogging.

Thanks to an intelligent detection system, it automatically adjusts the tension according to the type of material used, ensuring a smooth and precise feed, even during long high-speed prints.

Combining high-speed performance, the dual extrusion system of the UltiMaker S8 allows simultaneous printing with two materials or two colors without compromising precision, making it one of the fastest dual-material FDM printers.

With a optimized nozzle change system and a rapid heating process, prints are completed with maximum efficiency and without time loss due to filament changes (insertion, purging).

With the UltiMaker S8, you benefit from the UltiMaker ecosystem, offering full compatibility with Cura software, the Digital Factory platform, and NFC-equipped materials. Thanks to this synergy, print management is simplified, optimized, and fully automated.

Additionally, a wide range of accessories and specialized tools ensures a smooth and efficient user experience, allowing users to harness the full potential of the printer with complete peace of mind.

Designed and manufactured in Europe, the UltiMaker S8 benefits from proven expertise and impeccable manufacturing quality. With years of innovation and experience in 3D printing, UltiMaker offers a reliable and durable machine tailored to professional and industrial demands.

This printer guarantees exceptional precision and unmatched robustness, ensuring an optimal return on investment for users.

Beyond the revolution in printing speed, UltiMaker integrates advanced features designed to optimize the user experience and that have made it famous. These cutting-edge features position the UltiMaker S8 as one of the most high-performance professional 3D printers.

The UltiMaker S8 is equipped with an integrated Air Manager that optimizes air flow management and filters up to 95% of ultrafine particles generated during printing. This system not only enhances user safety but also ensures a healthier work environment.

It also promotes thermal stability inside the print chamber, ensuring consistent and high-quality results.

The closed print chamber of the UltiMaker S8 ensures optimal thermal regulation (<50°C) by maintaining a consistent temperature throughout the printing process. Paired with a high-performance heated bed (up to 120°C), it enables printing with a wide variety of materials, including technical polymers that require a controlled environment.

This feature significantly improves layer adhesion, reduces warping, and ensures reliable, high-precision prints.

The UltiMaker S8 is equipped with a flexible PEI print bed that makes it easy to remove prints without risking damage to the pieces. This coating ensures excellent adhesion for the first layers, both for standard and more technical materials.

It features 25 magnets and 4 alignment pins: a clever design that simplifies handling and ensures better repeatability of prints, even for the most demanding projects.

The UltiMaker S8 features an intuitive touchscreen that offers smooth navigation and simplified access to printing settings. Its ergonomic interface allows for quick and efficient control of settings, even for novice users.

Additionally, an integrated camera allows remote monitoring of print progress, ensuring real-time tracking and optimized management of printing tasks.

With its automatic calibration system, the UltiMaker S8 precisely adjusts the bed and nozzle height before each print. This feature eliminates human errors, ensures a perfect first layer, and optimizes the adhesion of printed parts.

Users enjoy a hassle-free experience, with consistent results and a significant reduction in print failure rates.

With a print volume of 330 x 240 x 300 mm, the UltiMaker S8 allows you to print large parts in a single print, eliminating complex assemblies.

This capacity opens up numerous possibilities for professionals looking to produce functional prototypes, detailed models, or series of parts with great flexibility. Ideal for design offices, engineering, and industrial manufacturing.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

330 x 240 x 300 mm

60 microns

500 mm/s

PLA, ABS , PETG, PC, Flexible, Nylon, Filament Support, Composites, PVA, HIPS, ASA, PP

Specifications for Ultimaker S8

Technology / Product

Extrusion

Heated bed

Specific equipment

Software

Installation / Prerequisites