The Complete Package Raise3D DF2 allows you to start professional resin 3D printing with all the necessary tools to successfully complete your projects. The DF2 3D printer offers impressive technical specifications and is a reliable choice for professional printing tasks.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 3500 products

A wide choice of products from the biggest brands

The manufacturer Raise3D is renowned for its cutting-edge FDM 3D printing solutions. Since its inception, the company has focused on providing high-end 3D printers with innovative components and operating systems, while consistently maintaining reasonable pricing for a wide range of professional users.

This commitment has propelled Raise3D to the top ranks of FDM 3D printer manufacturers, earning recognition through various international awards.

To diversify its offerings and meet the growing demand in the 3D printing market, Raise3D has expanded its product line by introducing the DF2 resin 3D printing solution.

This ecosystem, based on DLP (Digital Light Processing) technology, includes the DF2 3D printer, the post-processing stations DF Wash and DF Cure, the automatic resin feeding station, as well as 3D printing resins and the slicing software ideaMaker, specifically optimized for resin 3D printing.

Discover the many advantages of this next-generation DLP 3D printer with a unique professional ecosystem.

The 3D printer DF2 offers impressive technical specifications, positioning it as a professional resin 3D printing solution. Despite its compact dimensions of 450 x 400 x 730 mm, it provides a spacious build area of 200 x 112 x 300 mm.

Its Z-axis height allows the printing of larger parts when needed.

The XY resolution of 2560 x 1440 ensures accuracy for every print, regardless of model complexity or geometry. The printer can handle a maximum load of 10 kg on the Z-axis, with a printing speed of up to 25 mm/h (0.1 mm per layer).

The layer height ranges from 50 to 100 microns, providing flexibility in print quality. The DF2 comes with a resin tank, air filter, finishing box, toolkit, and smart build plate.

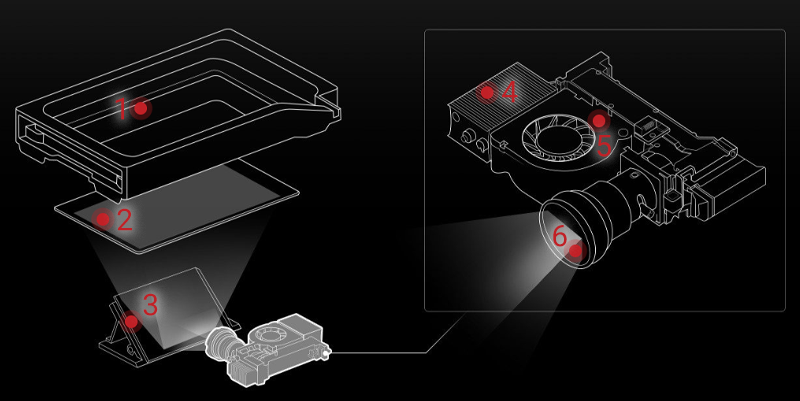

The 3D printer DF2 integrates Raise3D Air-Peel technology. Positioned between the bottom of the resin tank and the optical glass, this solution significantly reduces peel forces from 50 kg to 10 kg, speeding up layer separation during printing.

This innovation relies on an ultra-thin air film, ensuring smoother peeling, improving printing speed and the isotropic properties of printed objects.

The printer’s smart build plate integrates seamlessly with post-processing devices using embedded RFID chips.

These chips record critical information such as resin type and wash and post-curing parameters. This integration simplifies the management of wash and post-curing stages for operators, regardless of their familiarity with the produced objects.

With its smart resin management system featuring automatic resin refill, resin material auto-recognition, ultrasonic liquid level monitoring, and resin tank cleaning assistance, the DF2 efficiently manages resin throughout the 3D printing process, ensuring productivity and durability.

.jpg)

The third generation of the smart lattice support further improves print success rates, reducing operator errors. Its advanced support structure also minimizes residual marks, reducing post-print sanding or finishing requirements.

The DF2 features a 10.25-inch touchscreen (1920 x 720) with Magic Layout, allowing users to edit print layouts and duplicate prints directly from the screen conveniently.

Another useful feature is the pre-print auto-inspection, ensuring all conditions such as resin type, resin margin, and build plate or feeding station installation are correct.

The DF2 integrates industrial-grade optical components that minimize losses and eliminate scattering, ensuring sharp layer reproduction for enhanced durability and image quality.

With a XY pixel size of 78.5 μm and a resolution of 2560 x 1440, this printer ensures precise and smooth surfaces. This quality is achieved thanks to high-quality components and integrated Anti-Aliasing technology.

The DF2 solution is specifically designed to work with Raise3D resins. The Raise3D resin catalog offers a variety of materials, from general use to engineering applications.

This resin offering meets the needs of small-batch custom production for rapid prototyping, as well as advanced industrial engineering focused on functional applications.

.jpg)

In addition to its own high-quality 3D printing resins, Raise3D forms partnerships with well-known brands such as Loctite and BASF to create co-branded 3D printing resins. Moreover, Raise3D is actively involved in the Open Resin Program (ORP), allowing the use of third-party materials.

Validated materials include Loctite IND405, Loctite PRO476, BASF Ultracur RG 3280, and RG 1100 B. This open-material approach provides users with access to a wide range of high-performance resins, ensuring greater flexibility, freedom, and inclusivity in the 3D printing process.

The Raise3D DF2 features a comprehensive ecosystem. It integrates slicing software and 3D printer or print farm management tools with industrial-grade materials and custom post-processing machines. In addition, users benefit from a complete set of ergonomic components for an enhanced experience.

This washing station provides a thorough cleaning using twin turbines, simulating hand washing with a dual-fan air drying system. DF Wash offers a controllable, efficient, and easy-to-maintain solution with automatic cleaning and drainage functions.

Essential components included in the package are an electric siphon pump, washing basket, waste disposal system, and hydrometer, ensuring full functionality. DF Wash has a 14 L tank, a maximum washing volume of 200 x 112 x 300 mm, and is compatible with solvents such as IPA alcohol, water, or TPM solvent.

This post-curing station stands out as a robust solution, offering versatile UV polymerization (LED 365/385/405 nm, mixed) and heating profiles (air heating up to 120 ºC), enabling traceable and customizable processes. Heat-resistant gloves and a tray are provided to facilitate usability.

The Raise3D DF2 solution provides fast printing, smooth surfaces, high precision and reliability, meeting the needs of engineering prototyping, manufacturing aids, and low-volume production.

It is clearly a production tool that fits perfectly in a professional environment.

Unlike bulky DLP processes found in other similar systems, the smart build plate with an RFID tag and the ease of use of the machines simplify the entire printing, washing, and post-curing process, ensuring consistency and efficiency.

The widespread compatibility with proprietary, co-branded, and third-party resins enhances the value of the DF2 solution, making it a must-have ecosystem suitable for any application.

Premium Support and After-Sales Service: Starting from your needs, we will guide you to the most suitable solution and provide long-term support for its implementation and daily use.

Official Reseller: Polyfab3D is a certified reseller of top brands, ensuring you get official products, exclusive access to the latest innovations, and priority technical support.

Fast Delivery and Customer Satisfaction: Polyfab3D is committed to providing you with an optimal and fast experience. Positive feedback from our customers rewards us and proves the reliability and efficiency of our service.

200 x 112 x 300 mm

50 microns

Specifications for Raise3D DF2 Complete Package

Technology / Product

Extrusion

Polymerization / Resin

Specific equipment

Software