- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

-

- 🎯 Services dedicated to professionals

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14-day return

Applications

- -35%

- Made In France

Applications

3D filaments are the essential raw materials for 3D printing. Their technical diversity allows adaptation to a wide range of applications, from rapid prototyping to final parts for professional or consumer use.

Choosing the right filament is therefore crucial to optimize the quality and durability of printed objects.

Applications of 3D filaments

Depending on the nature of the project and specific needs, some filaments are preferred for their flexibility, others for their chemical or thermal resistance, while some meet strict standards, such as for food contact or electrical safety.

Flexible filament

Flexible filaments, especially TPU (thermoplastic polyurethane) and TPE (thermoplastic elastomer), offer excellent elasticity while maintaining good mechanical strength. They are ideal for producing soft parts such as seals, protective covers, or components requiring shock absorption.

This flexibility also enables creative applications in fashion, personalized accessories, as well as medical prosthetics and orthotics where comfort is essential. Printing requires, however, precise adjustments to avoid clogging, especially with calibrated extrusion flow and reduced speed.

Support filament

For complex parts with overhangs or delicate internal structures, support filaments are essential. These materials, often water-soluble like PVA or soluble in special solvents, allow printing shapes otherwise impossible.

They greatly facilitate post-processing by allowing supports to be removed mechanically or chemically without damaging the main part. This type of filament is indispensable for professional users seeking a high level of detail and finish, especially in engineering and jewelry sectors.

Flame retardant filament

Flame retardant filaments are formulated to resist fire spread and high temperatures. They are essential in sectors where safety is paramount, such as aerospace, railways, automotive, and electronics.

They ensure compliance with stringent fire safety standards and are used for parts that must maintain integrity in case of fire. Besides thermal resistance, they often offer good dimensional stability under heavy mechanical stress.

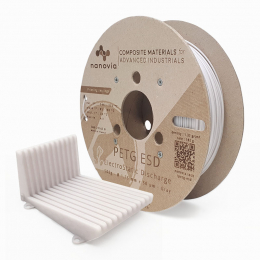

ESD filament (electrostatic discharge)

ESD filament is designed to prevent the buildup of static electricity, which can be hazardous in certain industrial or laboratory environments. These filaments contain conductive additives that dissipate electrical charges.

They are used to manufacture housings, holders, or tools that must absolutely prevent electrostatic discharges that could damage sensitive electronic components.

The use of ESD filaments is recommended in controlled environments to ensure the safety and reliability of installations.

Medical / antibacterial filament

Medical or antibacterial filaments contain specific additives that limit microbial growth on the surface of printed parts. They are particularly valued in the production of medical instruments, dental devices, or everyday objects with high hygiene requirements.

These materials comply with strict biocompatibility certifications and are suitable for prolonged skin contact or use in sterile environments. Their increasing use opens new possibilities in personalizing medical equipment and rapidly producing clinically validated prototypes.

Food contact filament

Filaments certified for food contact ensure the absence of toxic substances that could migrate into food. They are essential for making utensils, containers, or even food packaging printed by 3D printers.

These filaments undergo rigorous testing according to food safety standards, guaranteeing safety and durability. Their use enables innovation in gastronomy, personalized packaging, and functional prototypes for the food industry.

Waterproof / water-resistant filament

Waterproof filaments are designed to produce parts resistant to water and other liquids. They are widely used for electronic enclosures, seals, hydraulic components, or any application requiring long-lasting water resistance.

Thanks to their low porosity and excellent layer adhesion, these filaments provide durable and reliable prints even under moisture exposure or corrosive substances. They are the preferred choice for functional prototypes and technical parts in demanding environments.

Burnout wax filament

Burnout wax filaments represent a significant innovation in jewelry, dentistry, and industry. They enable printing precise models that are subsequently used to create molds via lost wax casting processes.

Due to their specific composition, these filaments burn completely without residue during the burnout phase, ensuring flawless and accurate reproduction of the final metal object. This type of filament opens the door to highly technical and precise additive manufacturing.

Conclusion

The variety of 3D filament applications reflects the rapid evolution of 3D printing technology. From DIY to industry, each filament type meets specific criteria to perform according to technical, aesthetic, or regulatory requirements.

Understanding these different categories enables users to choose the right material and fully exploit the potential of their 3D printer for reliable, innovative, and professional results.